Results 1 to 10 of 24

-

07-01-2017, 04:41 AM #1Senior Member

- Join Date

- Jul 2011

- Posts

- 2,110

Thanked: 459 Recent Jnats - A thread of new stones

Recent Jnats - A thread of new stones

I have been whining about the price of jnats lately, and the surge of junk stones now being purpose sold. Someone somewhere is boasting about their "market making".

This is at the top of my mind because I have been buying a huge pile of jnats. I'll post them as I get them. This one I got tonight. I don't know how to get a stone like this cheap. It's about a 1.5 KG stone, so not small. it's a bit misshapen, but almost white with black renge in the middle, and even though the arrangement isn't perfect compared to a bright white perfectly square stone with uniform renge from top to bottom, I still had to pay $325 for it when all was said and done. Don't tell my wife!!

It is incredibly strong cutting and smooth - not billowy smooth like a soft stone, but very firm and smooth. These pictures came from the seller, but tonight I tried it on a vintage english chisel, a japanese chisel and a chinese high speed steel chisel. It cut all of them fine and made an incredibly bright edge. It is the finest combination of fine and strong cutting that I have gotten in any stone, but I have learned to spot them (which is not hard when you've bought the wrong thing enough times).

This would not be an ideal knife stone, but it is very ideal for the fine side of suitas for tools, which is why I got it. I'm sure it would easily finish a razor, but I won't chance guessing at that - I've got razors coming also, so I will see if that's the case.

I also got an ohira renge suita about the same time, about the same price. It will be a coarser stone than this. This one would peg around 9 fineness on aoki takeshi's scale, and less fine only than the finest green stones. I may see (time permitting) if i can get stria from these on a microscope.

This one breaks the ice. I have gotten other stones from dealers in japan, but not directly off of an auction. The cutting power and fineness of this stone is pretty rare - a very LUCKY purchase, because from this distance, it could've ended up being coarse and scratchy and I just have to lump it.

No clue on mine, but would speculate okudo or okunomon. It doesn't matter. I'm keeping this one unless i go broke.

-

The Following User Says Thank You to DaveW For This Useful Post:

Hirlau (07-09-2017)

-

07-02-2017, 07:58 PM #2Senior Member

- Join Date

- Jul 2011

- Posts

- 2,110

Thanked: 459

I was a bit wrong about shipping of other stones. It'll be a few days before I get more, but I should have 10 or so, maybe 15 coming (I can't remember) over the next couple of weeks.

I broke out a razor that I got directly from japan in a group. I didn't notice in the picture that the tip of the razor below made it look like the whole thing was dropped or something was run into it (surprise damage that explains the low price). So I ground the end off (only about 1/16th), reshaped it quickly and honed it on a washita and then finished it on this suita. This is far and away the finest fast cutting suita I've come across. An excellent shave, one weeper, otherwise as comfortable and sharp as any finisher I've used - better than a thuri, much keener than coti, but the bevel is bright without any stray scratches to the eye and not the slightest hint of cloudy finish. As far as honing a razor, the bevel set and hone was probably about 4 or 5 minutes, then another couple of minutes on a vintage linen followed by horse leather. Tanifuji knew how to finish razors, and they are extremely easy to set up. Washita sets the bevel and leaves it almost finished all at once - it's almost too easy.

I realize that sometimes people get online and say they bought things that they didn't, so I put something that can't be attributed to anyone else in the background - a norris no 6 copy that i finished a week ago and then gun blued

https://s16.postimg.org/rrwm8qt1x/013.jpg

https://s16.postimg.org/nk1tzzrmd/014.jpg

(just looked at the uploaded pictures. Not much in focus as far as the razor goes. I need to go look at a few listings to reshape the end a little bit to look more stock. The stone is yellowish more than the auction because the swarf is yellow/orange once it dries. Overall, an expensive stone for one of this shape, but a very good one. The next suita coming in the mail is a big ohira suita - it looks nicer but I doubt it will be as good).

-

The Following 2 Users Say Thank You to DaveW For This Useful Post:

Hirlau (07-09-2017), Toroblanco (07-09-2017)

-

07-05-2017, 10:59 PM #3Senior Member

- Join Date

- Jul 2011

- Posts

- 2,110

Thanked: 459

What I believe to be an ohira suita with some renge. Not a stone for someone who doesn't like lines!

Big (45mm thick) and not particularly expensive for what it is. I could tell from the listing that it might be a bit soft for my taste, so I have bought three. The others have yet to arrive. The price was good enough that I can get out of the trial without a loss.

-

The Following 2 Users Say Thank You to DaveW For This Useful Post:

Hirlau (07-09-2017), Toroblanco (07-09-2017)

-

07-07-2017, 05:25 PM #4Senior Member

- Join Date

- Jul 2011

- Posts

- 2,110

Thanked: 459

Not that it's important, but the above suita will also finish a razor. I suspect that I'm buying these stones from is a dealer and he's not using the same name elsewhere for reasons I'm not sure of. But the stone above showed up with a mirror finish on the surface, which seems unusual to me for a suita. I am hoping that it will actually lose some of that fineness once I work through it, as a fast stone a little less fine is much more useful for day to day tool work.

I think the dealers who deal in stones like this (like takeshi kuroda) would call the fineness something like 8.8 and the hardness, we'll have to see after the skin wears off. It will release particles when jigane is involved, but still put a 90% polish on hagane. The first stone at the top will put a bright polish on hagane, but at the same cutting speed. It is a little bit better of a stone and I suspect it's not ohira as the second one is.

Both still lovely stones, and this one strong cutting and fine for an ohira - much better than the tomae stone that is sold from ohira by the tool dealers in the US for an inflated price ($400 for 30 type and $900 for 24 type). Both stronger and finer cutting, even if it loses some fineness.Last edited by DaveW; 07-07-2017 at 05:28 PM.

-

The Following User Says Thank You to DaveW For This Useful Post:

Toroblanco (07-09-2017)

-

07-09-2017, 01:42 AM #5Senior Member

- Join Date

- Jul 2011

- Posts

- 2,110

Thanked: 459

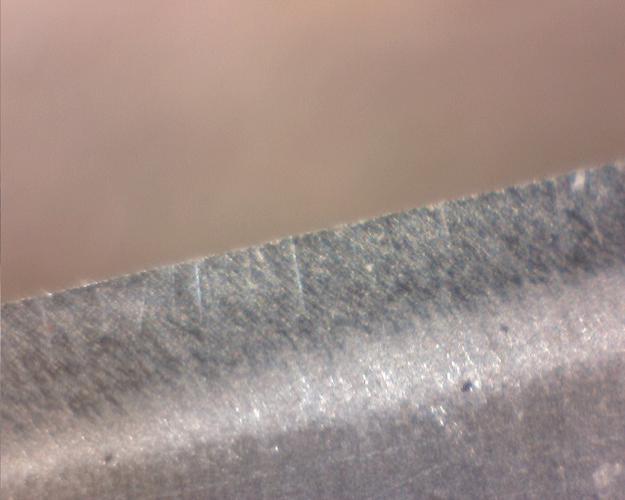

Pictures of the edge from these stones. I have a bunch more stones on the way, just haven't tried them yet, so I'm treading water.

This is the edge from the ohira suita (the second one above). It's on a henckels carbon steel razor (#13). I haven't shaved with it yet, but it looks very uniform and should be comfortable and reasonably sharp. bevel appears to have been rounded by the prior owner due to pressure, which isn't surprising given that the primary bevel looks a bit too large to the naked eye. That will eventually work itself out in future honings.

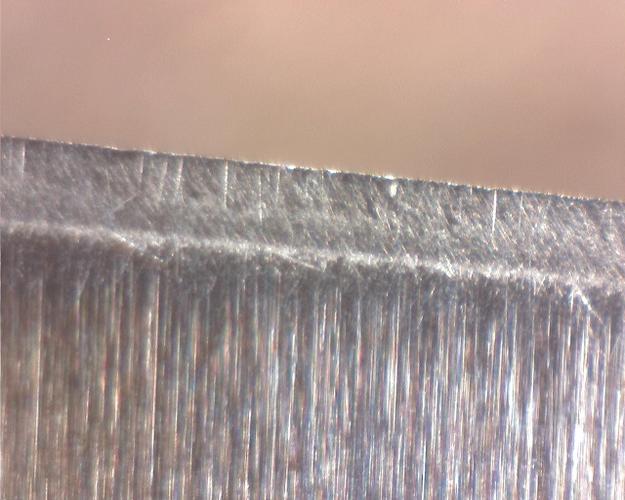

This is the edge from the misshapen stone at the top, I'm going to guess it's Okudo, but who knows? It could be anything. I have seen stones with coloration like that form Okudo, though. Open to any guesses. This is a stainless friodur. The edge looks pretty rough, and I wouldn't have guessed it because the shave was comfortable today with it. I think it takes a beating from the linen. I always guessed that these razors were 440C and down a step or two in hardness vs. carbon steel to make it so that they wouldn't be a bear to sharpen on natural stones. I'm still guessing that's true. I will hit the hones again with this one. Neither of these razors got more than 10 minutes of attention from bevel set to hone, linen and strop. There are some defects in the edge on this under the microscope at various spots, which will mean that I should get a look at the edge after the stone and before the linen and then after the linen to see if what I suspect is true. That said, the shave was great, and HHT is passed easily at 4. I could see that the edge wasn't perfect just using the naked eye - after the linen, that is, but I have reasonably good eye sight - not surprised to see it looking a little rough close up.

If the prominent scratches are from the washita (only used two stones), then that would suggest a little more time on slurry on the suita is in order. I have a bunch of razors to set up, and want to get this streamlined and quick, but evidence leans toward a few more minutes being in order.Last edited by DaveW; 07-09-2017 at 01:48 AM.

-

The Following User Says Thank You to DaveW For This Useful Post:

Hirlau (07-09-2017)

-

07-09-2017, 07:49 PM #6Senior Member

- Join Date

- Jul 2011

- Posts

- 2,110

Thanked: 459

Following up, all with the friodur:

A picture straight off of the ohira stone - visible scratches (stone is on the hard side and doesn't release anything on clear water):

Then off of the okudo stone:

I can't really tell too much about the stones, though I think the misshapen one is a bit stronger cutting with finer grit.

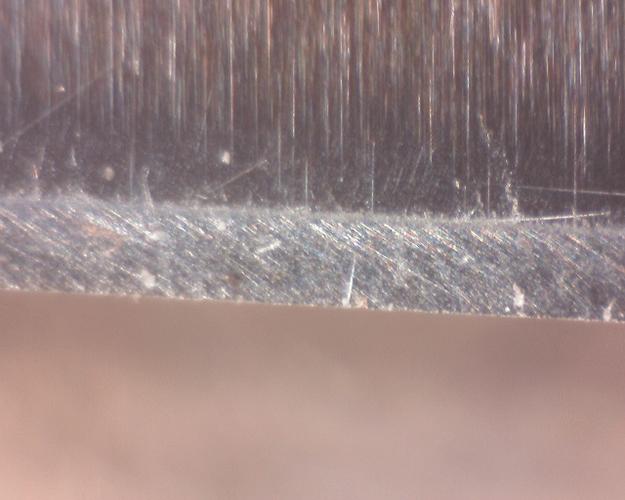

Stropping on both was leather only to avoid the linen. The edge is "quieter" looking.

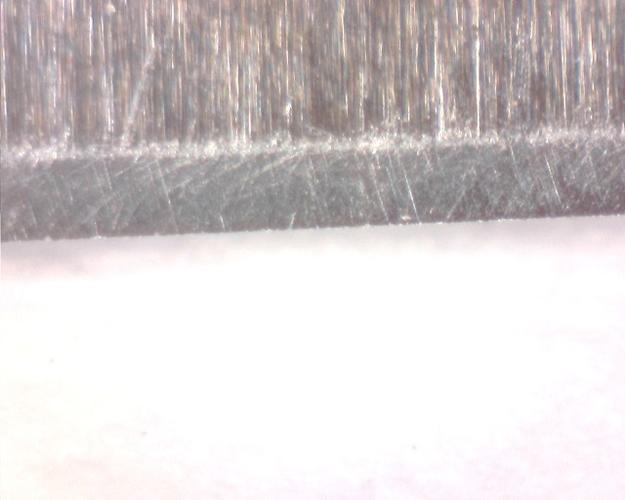

Then with the linen:

The edge does look a little rougher from the linen. This is the first razor I've looked at where that occurs. I suspect softness, but who knows? the carbon steel razor at the top, same maker, also hit the linen, and briskly, too. It shows almost no effect, which is what I'd suspect - I think hardness, though alloy could have something to do with it. Friodur razors were some of the first cryo treated goods as far as I know, which is supposed to tie the carbides into the matrix more evenly and prevent large grain failures, but from what I know of tools, even the finest powder metal alloyed stuff still fails at the edge a little more roughly than does good plain carbon steel. I would suspect that the friodur might have better wear resistance than a carbon steel razor, but we don't really ever test that shaving - we test impact, I would guess - like you'd see with a chisel. And chisels do best with carbon steel.

That said, the friodur is very very slow to rust, and despite the look of the edge, it seems to give a really nice shave. The grind on this one is wonderful, like as good as I've seen anywhere if you like a delicate grind.

In each case above, the total work is approximately 2 minutes, timed, plus another minute of linen and leather. 1 minute on slurried suita and then one minute on the suita discussed here on clear water or very close to it.

-

The Following User Says Thank You to DaveW For This Useful Post:

Toroblanco (07-09-2017)

-

07-09-2017, 08:03 PM #7Senior Member

- Join Date

- Jul 2011

- Posts

- 2,110

Thanked: 459

Curiously enough, the top razor that looks the best falls a little short when it comes to an actual shave. It shaves and doesn't pull, but it's just not quite there.

You just never know, I guess. Back to the hones for it to give it a touch up, and maybe a little back and forth on the linen and hones.

the friodur, still retaining a tiny bit of sparkles at the edge, shaves as well as I've had with anything short of stepping it up past my comfort level (meaning, if it were any sharper, I'd start to get weeps).

I've gotten more than one "razor" stone that falls short of these two suitas. At the same time, if I was at a job site 100 years ago, I might find them a bit too fine and hard to be practical in the cycle of carpenter's work.

-

The Following User Says Thank You to DaveW For This Useful Post:

Toroblanco (07-09-2017)

-

07-11-2017, 02:15 AM #8Senior Member

- Join Date

- Jul 2011

- Posts

- 2,110

Thanked: 459

Another stone arrived today. Hatanaka box, but I'm not so sure about the stone itself. It has developed a small crack at the surface and on the side.

Green, very hard, and aggressive. Not large particles, per se, but aggressive cutting.

Very possible that there's things I don't know about HTK, like a box like this without other labeling may be used for stones that don't measure up. And also very possible that the box is not for this stone.

It was finished smooth, but I lapped it, anyway, as I couldn't tell if the surface was truly flat or if it was just polished. Usually, it's easier to tell. A progression with ozuku tomonagura and diluting until clear water gets to here. Looks relatively uniformly polished to the naked eye, but the microscope shows scads of tiny scratches. Been a while since I had anything other than suita, so I will defer. Funny things happen with a cheap microscope like this and any aggressive stone, though - reflectivity sometimes exaggerates things. The edge looks decent. A linen and leather and I will shave with it tomorrow.

I would call the feel and slurry of this stone about the same as 8.9-9.0 particle size on takeshi aoki's scale. I like the white suita above better.

-

The Following User Says Thank You to DaveW For This Useful Post:

Hirlau (07-11-2017)

-

07-11-2017, 02:27 AM #9I used Nakayamas for my house

- Join Date

- Aug 2009

- Location

- Des Moines

- Posts

- 8,664

- Blog Entries

- 1

Thanked: 2591

-

07-11-2017, 02:30 AM #10Senior Member

- Join Date

- Jul 2011

- Posts

- 2,110

Thanked: 459

It is stamped only on the end. It's been used, though. I don't know how deep the original stamps would go.

I haven't seen a box without a stamp, either.

I have to try some tools on it. It's a very even stone, but aggressive. I'm so used to suitas, and it doesn't have that buttery feel that suitas have.

16Likes

16Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote