Results 11 to 20 of 66

Thread: Coti breaking glass HELP

-

01-19-2018, 02:31 PM #11

From the coupechouclub. There have been a number of versions of it.

As to the OP's problem, what is your sequence leading up to the coticule? I too would suggest not worrying about the HHT and using water only. My sequence usually is 1k > 3k > coticule with water. The coticule edge is always smooth for me, but I always need something more afterwards, paste, Thuri, or Welsh slate. Perhaps using briefly with water after 12k might help to calm any harshness. But I haven't tried this.Striving to be brief, I become obscure. --Horace

-

The Following User Says Thank You to Brontosaurus For This Useful Post:

Gasman (01-19-2018)

-

01-19-2018, 03:30 PM #12Senior Member

- Join Date

- Jan 2015

- Location

- Apex NC

- Posts

- 535

Thanked: 90

Was your coti an unknown layer? Did you strop before trying hht? I would spend sometime trying unicot and dilucot. You will find that counting really doesn't work all the time, but will give you an idea. These methods give you a good relative theory on using these stones and you just need to figure out how you and your stone can make that theory work.

Last edited by rideon66; 01-19-2018 at 04:57 PM.

-

01-19-2018, 04:48 PM #13illegitimum non carborundum

- Join Date

- Jan 2008

- Location

- Rochester, MN

- Posts

- 11,552

- Blog Entries

- 1

Thanked: 3795

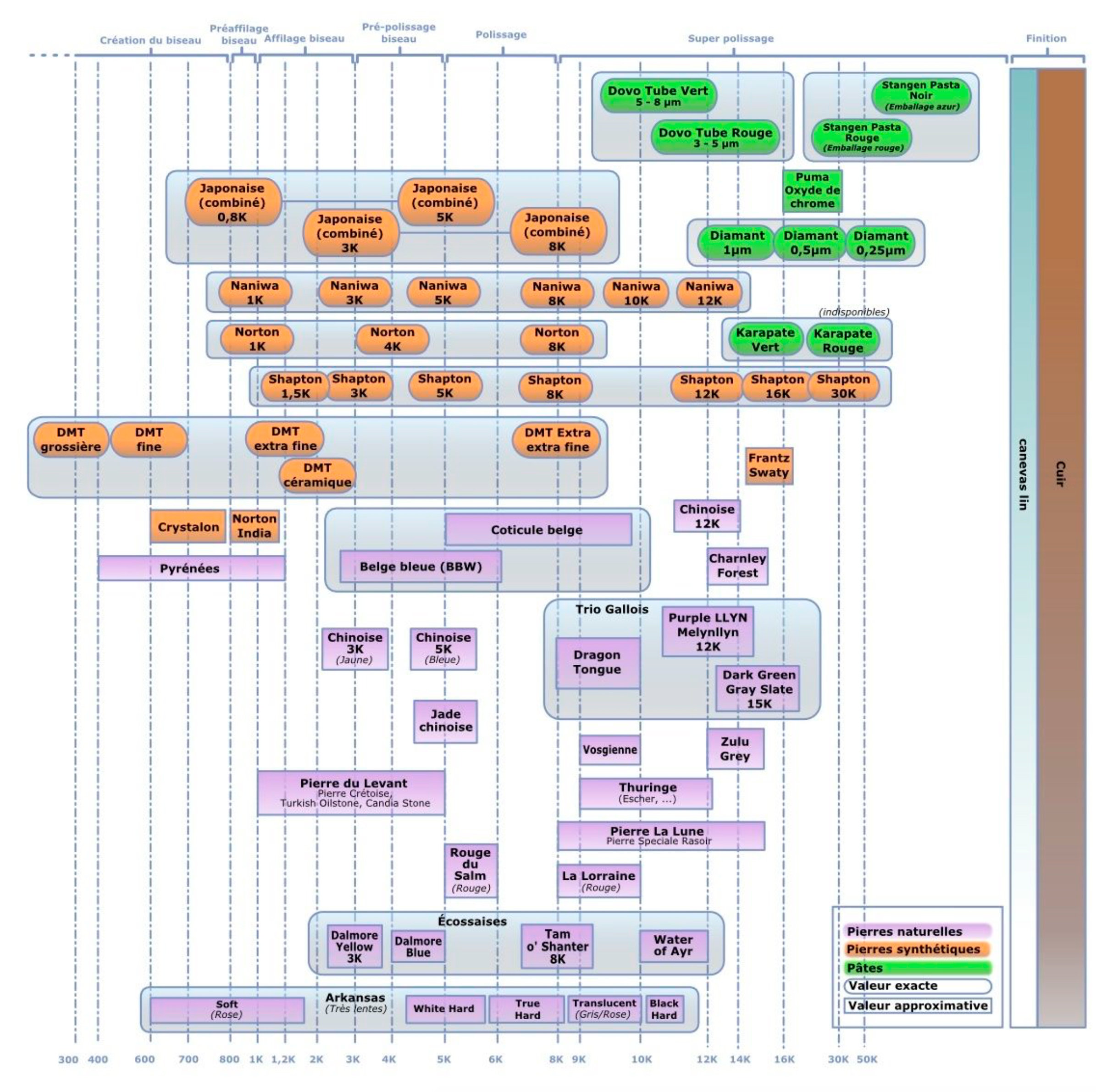

It remains utterly pointless to assign a grit rating to any natural hone. Grit rating refers to the SIZE of the grit put into the synthetic hone. Even in synthetic hones, the size is borderline useless. Consider a Swaty barber hone...

What is the "grit rating" for a Swaty? I have seen it described as ranging from 6k to, according to that chart, 16k. Now does anyone know what is the actual size of the grit in a Swaty?

It's about 600.

So how does it get called a 16k hone? It shouldn't. It isn't. There is a reason why barber hones never had grit ratings assigned to them. It's the same reason that NONE of the natural hones EVER had a grit rating assigned to them until the internet came about and too many folks decided that high numbers are better than low numbers.

So why isn't it called a 600 grit hone. It shouldn't. It isn't. Barber hones have factors to consider other than just grit size. Grit density and the binder used for the hone also matter. Most importantly, for barber hones the surface prep is one of the key determinants of how the hone performs. The surface of the hone, in which those big chunks of grit are embedded, is burnished to smooth out the cutting surface of the peaks of all of those big chunks of grit. They still are big, but their peaks are all rounded over, effectively dulling their cutting capacity. The condition of the hone determines how it cuts and that is why my Swaty does not cut like your Swaty. (My Swaty is better.)

Why did we get onto barber hones? I was ranting about natural hones...

Every natural two sided coticule is cut from the junction of a light vein and a dark vein. Those two veins have been right next to each other for millions (and millions) of years, yet they cut steel completely differently. Two sides of a cut out rock only an inch thick performs differently, yet somehow we try to assign a number to rocks that were mined meters or kilometers apart from each other. Numbers just don't tell the entire story of how a hone cuts.

What about scratch pattern? So many numbers are assigned by scratch pattern in comparison to "standardized" patterns but depth of scratch pattern varies by total pressure, pressure distribution, prior prep of the steel, the surface prep of the hone, and again, the individual characteristics of the particular hone being tested. They just are not all the same. Two rocks that spent millennia only a few inches apart can cut completely differently.

There simply is no point in assigning a grit rating to a natural hone. Coticules tend to produce comfortable shaving edges. That is how they are rated.Last edited by Utopian; 01-19-2018 at 04:50 PM.

-

The Following 2 Users Say Thank You to Utopian For This Useful Post:

DoctorNick (01-19-2018), Marshal (01-19-2018)

-

01-19-2018, 05:09 PM #14

yes,

i would like to add, it's interesting dont forget the profit that gives the mud action with these stones ( coticules)All you will do without taking the time,

Time will not respect it.

-

01-19-2018, 05:42 PM #15

Coticules are my favorite hones EVER. I love how they look perform, smell...cut..etc. But they are NOT magical hones that can set a bevel and polish a 16K edge on a razor at the same time for EVERY SINGLE ONE OF THEM. It's not possible.

Some are slow

some are fast

Some leave a very harsh edge

Some leave a nice edge for shaving.

Some create large slurry and It dulls an edge after a few passes.

Some don't dull an edge with slurry....

I really recommend you get a coticule FOR RAZORS from Maurice at the actual Quarry that manufactures and sells these hones.

-

01-19-2018, 10:21 PM #16

You caught it Utopian, why i asked where the chart came from. I dont have one of those barber hones but from all ive read, i just couldnt see one being a 16k. Thanks for bringing it up.

It's just Sharpening, right?

Jerry...

-

01-19-2018, 10:58 PM #17

I got lucky with my first coticule, I think. I bought a new La Veinette from a local seller who knows his stuff and picked this one for me. I, like you Disburden, love coticules. Too much, it would seem, as, after I went through the pain of learning how to use my LV well I then went and bought five more stones of different veins and am still to commit the time they deserve to learning to use them most effectively.

I recently had to take a razor I'd finished on a Petite Blanche I've recently picked up back to my Veinette because it wasn't shaving anything like it did off my LV after what I thought was a careful hone on this finisher. Since then, I've learnt better to use my PB and can but a good, finished edge off it. It's still not as keen as my Veinette edge and it almost definitely wouldn't feel anything like as keen as a synthetic finisher, simply because it's not that kind of stone. For some razors and shavers that could be an advantage.

I don't put much store by the HHT when I'm honing with coticules. I also have a coarse beard and can get an edge off my stones that can very nicely shave me, closely and smoothly. I love the feel of a coticule edge on good steel and prefer it to a shave-ready edge made so by synthetics. When I was building up my skill honing on my first coticule, I didn't get nearly as smooth a shave as I do now and have taken razors I learnt to hone on back to the same stone and improved the edge. The honing experience and technique is dramatically different to that of synthetic hones.

I'd keep persevering. Maybe introduce a dot of washing detergent when you get to the finish on plain water, I think it helps. If you think it's autoslurrying, then a trickle of running water in the sink at finish might help. Try finishing on a very light slurry, rinsing razor and hone, stropping, then finishing on water, see if that works. Take your time and see if you get better results. I wish you luck.Hanlon's Razor: Never attribute to malice that which is adequately explained by stupidity.

-

The Following User Says Thank You to DoctorNick For This Useful Post:

Utopian (01-20-2018)

-

01-19-2018, 11:13 PM #18

-

01-19-2018, 11:42 PM #19Senior Member

- Join Date

- Dec 2014

- Location

- Virginia, USA

- Posts

- 2,224

Thanked: 481

I take large issue with the ascribed ranges.

I've never seen anyone claim their Dragon's Tongue to be an improvement over an 8K hone for example. Mine is a side step from a Norton 8K, certainly no better. You can safely knock those ranges down 2-3K a piece and be more in line with performance. The Arkansas stones have True Hard, then Translucent, Then Surgical Black as progressive from lest fine to most fine, however all 3 have the same range of performance and I think Black Hard is in a fair position for a proper Arkansas stone. They don't call the Chinese 12K the People's Hone of Indeterminate Grit for nothing, some are damn good but 12K they are not.

And then there's the barber hone. Franz Swatys are good, I wouldn't trade mine for anything. But I don't have a single barber hone that performs in the 16K range, and I'm not aware of any Swatys that perform that well. My assessment of mine places it as a side step from Norton 8K (this is in a way arguable - the Swaty is a heck of a lot faster in spite of the surface difference.

But the chart isn't really the operative issue the OP brought up. So enough about that.

With respect to coticules...I'm still trying to figure mine out. I've played with it a lot, the last time I used it I got pretty good results. My current operative theory is that garnet laden hones behave quite different from anything else I've experienced. I suspect as someone mentioned earlier the size difference in garnet from stone to stone plays a large part in the operating issues. Larger garnets cut deeper, and in a harder binder perhaps more liable to be shattered when we scrape a diamond flattening stone across them. Someone floated that theory and I spent a great amount of time scrubbing the surface of my stone with it's rubbing stone in an attempt to smooth it out and 'undo' any potential damage done by my lapping plate shenanigans. After that it imparted a fairly good edge with nothing more than plain water, maybe some shave lather I can't recall off the top of my head.

These things can certainly be a bear to work out, and I would encourage you to keep at it. I haven't given up on mine yet, however the test razor that I set aside for coticule maintenance is not yet due for a touch up so the experimentation is at a stand still.

-

01-20-2018, 01:33 AM #20Senior Member

- Join Date

- Jan 2015

- Location

- Apex NC

- Posts

- 535

Thanked: 90

It is not a theory about shattering garenets with diamond plate. It is a magnification photo in grinding and honing the one about coticule.

-

The Following User Says Thank You to rideon66 For This Useful Post:

Disburden (01-20-2018)

90Likes

90Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote