Results 1 to 10 of 36

Hybrid View

-

06-06-2019, 04:43 PM #1At this point in time...

- Join Date

- Jun 2007

- Location

- North Idaho Redoubt

- Posts

- 26,985

- Blog Entries

- 1

Thanked: 13234 Follow Up

Follow Up

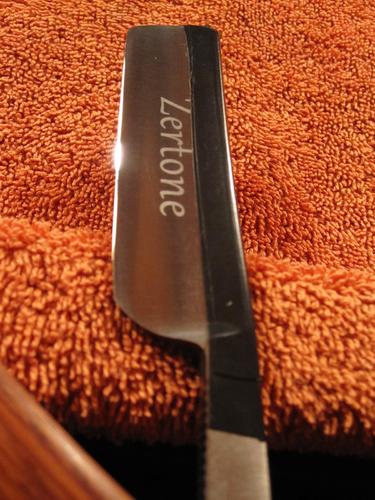

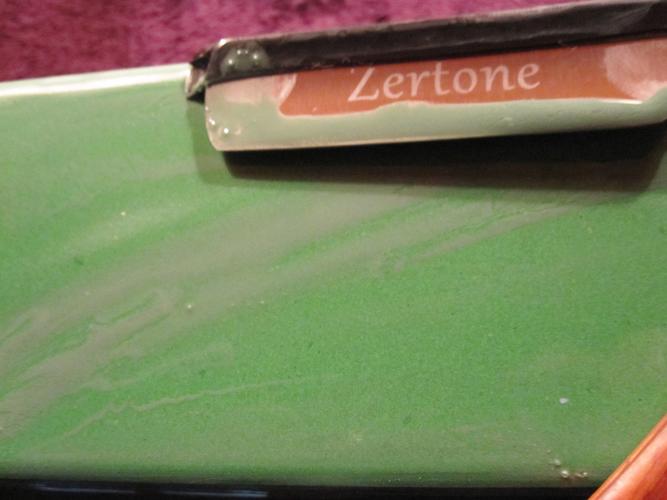

Okay so The razor arrived and I put it through the process,, here are all the results

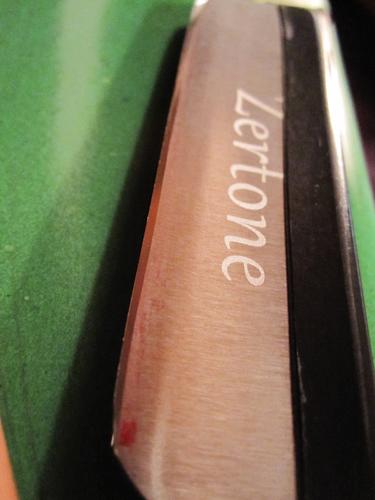

Looking at the razor in hand I think the same thing as I thought when Cory first contacted me, ZY by another name..

I am sure most of you know that you can have just about any name printed on these if you order 100 or more

Here is the first look

Note: I just automatically started with two layers of tape, I have learned things over the years hehehe

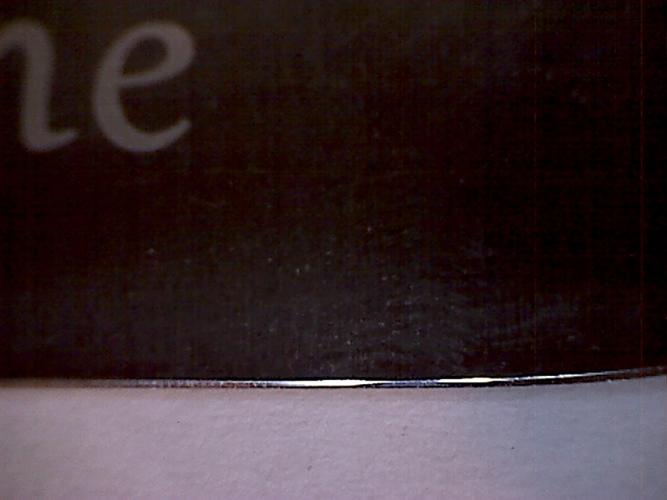

USB starting off

The Magic Marker Test showed that the bevel was set with the spine off the hone, so it had to be fully re-set to even figure out if it was going to hold

A good sign is that the razor is NOT falling apart on the Chosera 1k leaving an acceptable amount of Grey swarf and not the huge amounts of Black sludge from the Pakistani RSO's

Bevel set and passing the Arm Hair Tests and no huge glaring deficiencies

So I moved onward and upward."No amount of money spent on a Stone can ever replace the value of the time it takes learning to use it properly"

Very Respectfully - Glen

Proprietor - GemStar Custom Razors Honing/Restores/Regrinds Website

-

06-06-2019, 04:50 PM #2At this point in time...

- Join Date

- Jun 2007

- Location

- North Idaho Redoubt

- Posts

- 26,985

- Blog Entries

- 1

Thanked: 13234 Finish and SOTD

Finish and SOTD

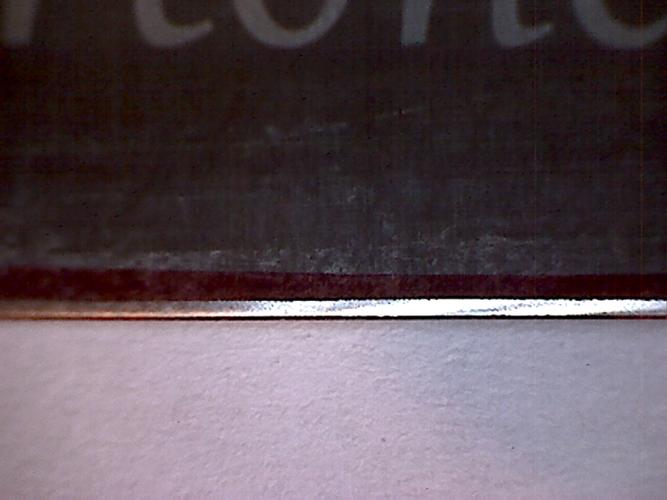

I went from the Chosera 1k t0 the 5k and 10k the edge held without any chipping or failure.

I decided on the Black Thuringen to give it a good face friendly feel to the edge,

I got a CCS from the edge, checked under Magnification for edge degradation and found none so it is ready to head home

**** Disclaimer, I am by no means recommending to go buy one, as I have no idea how long the edge will hold... All I can say for sure is that I was able to create an edge that held up to a shave***"No amount of money spent on a Stone can ever replace the value of the time it takes learning to use it properly"

Very Respectfully - Glen

Proprietor - GemStar Custom Razors Honing/Restores/Regrinds Website

-

06-06-2019, 06:34 PM #3

So like a gold dollar without the trouble of having to grind away at the stabilizer? How did you find the grind Glen? Namely at the heel and the tip.

-

06-06-2019, 08:28 PM #4Junior Member

- Join Date

- May 2019

- Location

- North Carolina

- Posts

- 8

Thanked: 0

oh wow it's looking real good. I really appreciate the work you did on it.

-

06-06-2019, 09:52 PM #5At this point in time...

- Join Date

- Jun 2007

- Location

- North Idaho Redoubt

- Posts

- 26,985

- Blog Entries

- 1

Thanked: 13234 "No amount of money spent on a Stone can ever replace the value of the time it takes learning to use it properly"

"No amount of money spent on a Stone can ever replace the value of the time it takes learning to use it properly"

Very Respectfully - Glen

Proprietor - GemStar Custom Razors Honing/Restores/Regrinds Website

-

06-06-2019, 10:59 PM #6

Good show! I am curious to give it a whirl. If they provide a decent shave, maybe they could make good freebie razors to introduce friends to the fold.

-

06-11-2019, 01:19 AM #7Senior Member

- Join Date

- Dec 2014

- Location

- Virginia, USA

- Posts

- 2,224

Thanked: 481

Little bit of research reveals the steel used in those razors is S45C - A medium carbon steel typically used for machine/structural use. The part of the description taht caught my eye:

So assuming they heat treated it properly, maximum hardness you could expect is a rockwell 46, typically for straight razors we're looking for mid 50s to low 60s. There's a bit of a trade off, at the higher end of the rockwell scale it's hard to remove material and get a working edge, on the lower end it's fast to sharpen because the steel wears faster, which leads to faster dulling as well. So it's probably a little on the soft side, and given Glen's test probably takes a nice edge but loses it faster than we would like. Slightly prettier/better ground Gold Dollar would be my guess.JIS S45C grade carbon steel is widely used in machinery manufacturing, good mechanical properties of this steel. But S45C Grade Steel is a medium carbon steel, hardened performance is not good, 45 steel can be hardened to HRC42 ~ 46. So if you need to surface hardness, but also hopes to play 45 # steel superior mechanical properties, often 45 # steel surface carburizing, so you can get the required surface hardness. JIS S45c steel are mainly used for a variety of motor shaft, automotive parts.

Which means it's serviceable, you'll just be touching it up more than a higher quality blade. I can understand why folks wouldn't want to spend $100-$200 on a newer quality carbon steel blade. But my Gold Dollar edge typically lasts less than a month's worth of shaves. About 20 daily shaves is the longest it's lasted without a touch up. Meanwhile I have vintage razors bought off ebay (for probably less than I spent on the Gold Dollar) that were made before WWII that will hold an edge for several months.

-

The Following 2 Users Say Thank You to Marshal For This Useful Post:

corybrett (06-11-2019), criswilson10 (06-11-2019)

-

06-11-2019, 01:22 AM #8Junior Member

- Join Date

- May 2019

- Location

- North Carolina

- Posts

- 8

Thanked: 0

I should have it tomorrow according to tracking. Now I do have a strop and I am lead to believe it needs to be stopped before each shave. is that correct?

71Likes

71Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote