Results 21 to 30 of 56

Thread: Arkansas Stones

-

06-26-2019, 01:41 AM #21

I wish I had a huge-ass stone like that. Maybe one day... You took the thought right out of my head!

There are many roads to sharp.

-

06-26-2019, 11:43 PM #22

-

06-27-2019, 12:38 AM #23

No, I wouldn't let go of an airport runway like that! I've had my 8x3" SB Ark and my smaller vintage Norton trans for a few years now, and don't imagine I'll sell them. Pretty much every finisher I try, I compare to those two for crispy surgical precision and smoothness to boot. And lay off of that 80's crack, ya hear?

There are many roads to sharp.

-

06-28-2019, 06:23 PM #24

Last night I decided to have a lapping-fest. By the time had done the Translucent I had nothing left in me. It took an age and I stuck with 120 grit instead of going down to 60 grit because im crazy.

Finished it on 600 grit SIC.

This morning I noticed something odd. I am assuming this is natural.

Have a look at the markings underneath the surface..

I have still yet to shave off them.

Notice the 3rd one along is jet black.

All four with a massive MK31 to give you a reference

-

The Following User Says Thank You to JOB15 For This Useful Post:

ScoutHikerDad (06-28-2019)

-

06-29-2019, 04:25 AM #25Member

- Join Date

- Mar 2016

- Location

- indiana

- Posts

- 54

Thanked: 9

Yup, those marks are natural. I have a 8x3x1/2 Norton Trans that looks similar on one side. If you can't feel them, then they just add character. So, so, envious of the size. Beautiful stones!

-

06-29-2019, 05:42 AM #26Senior Member

- Join Date

- Apr 2012

- Location

- Diamond Bar, CA

- Posts

- 6,553

Thanked: 3215

60 grit loose Silicone Carbide, a steel cookie sheet and grid mark with a Sharpie. Pencil will wash off with the slurry. Ink will also but you will get a good idea if you are flat.

Stay on 60 grit until you are sure you are flat

-

06-29-2019, 08:13 AM #27

A sharpie defiantly the way to go. A baking tray, that would be a bit too small for the 12" stones . I'm after some granite because I went straight through the marble.

I will start at sixty with the other 2 stones .

Also I decided to buy some honing oil instead of using soapy water . I figured they call them oil stones for a reason..

Cheers

-

06-29-2019, 11:05 AM #28

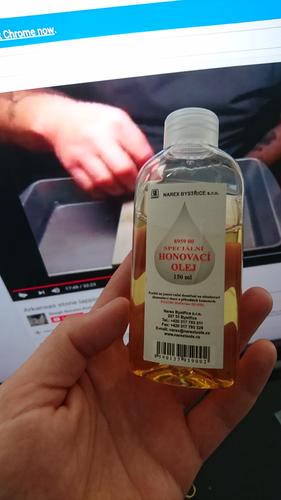

Received my honing oil today . £10 for 150ml and the bottle looked half empty ..

I gave the Sheffield 50 laps and the T.I 80 laps.

Just shaved with the T.I / Castle Forbes lime / Taylors of Old Bond Balm ..

I'm BBS with no stinging. .

These stones are gonna take time , years to understand and that depends on your understanding of the word "Understand".

An honour to use such a beautiful stone

All those white parts disappeared when I added oil to the surface ..Last edited by JOB15; 06-29-2019 at 11:04 PM.

-

06-30-2019, 12:03 AM #29Senior Member

- Join Date

- Apr 2012

- Location

- Diamond Bar, CA

- Posts

- 6,553

Thanked: 3215

Yes, that looks like a stone were the black and translucent transition, I have a small one more grey with black and white veins running through it. It is translucent and super finisher.

I use a steel baking sheet, glass and stone will abrade with 60 grit silicone carbide and at least you are losing half of your cutting power. Steel remains flat and will also contain the slurry, add a ½ teaspoon when you feel it is not cutting.

Stay on 60 grit until you are absolutely sure you are flat; the rest of the progression goes quickly.

Experiment with lubricants, pressure and laps, depending on how the stone face was finished and the stone, you can use more pressure that normal. Hundreds of laps are not uncommon.

If you use oil it will wash off easily with dish soap or degreaser to prevent going rancid.

-

06-30-2019, 12:14 AM #30

125Likes

125Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote