Results 31 to 40 of 56

Thread: Arkansas Stones

-

07-01-2019, 10:31 AM #31Senior Member

- Join Date

- Jan 2019

- Location

- north florida

- Posts

- 125

Thanked: 10

I am not understanding the purpose steel the baking sheet?

I’ve always used a granite tile, or counter top cutout, confirmed flat with straight edge.

-

07-02-2019, 01:30 AM #32Senior Member

- Join Date

- Apr 2012

- Location

- Diamond Bar, CA

- Posts

- 6,553

Thanked: 3215

Years ago, I used glass and granite countertop cutoff, available from Habitat for Humanity for a couple dollars.

I started using a steel baking sheet primarily to contain the slurry and found unlike glass and granite it does not abrade easily. Glass and Granite abrade quickly under 60x Silicone Carbide.

Flat is really not the issue, flattish is good enough. At 60 grit you are hogging off material, the goal is to remove any un-lapped pockets that will surface later as the stone wears.

If you are grinding the stone and the substrate you are reducing the effectiveness of the grit. A steel baking sheet from the Dollar store solves all 3 issues, contains the grit, stays flat and is not a braiding the substrate, just the stone.

I have been using the same sheet for years and have tried it both ways, I lap a lot of hard stones and steel is faster, you can feel when the grit stops cutting aggressively and just add a bit more.

Here is an interesting post by Tom Liptonís, OX Tools on precision lapping granite lapping plates. The calibrating technician says that plates go out of flat because of air borne dust and tools repeatedly dragged across them. So, if airborne dust can make a granite plate go out of flat, (admittedly, very little, microns) surely 60 grit silicone oxide can do the same or more. Food for thought, talking about airborne dust, how clean is your strop?

He uses a steel lapping plate with 60um Diamond flour, (about 250 grit) to surface the granite, and says his lapping plate continues getting flatter with each use.

I am more concerned with speed, if I can contain the slurry and get flatness for free, itís a no brainer. ()

-

07-02-2019, 05:03 AM #33

I did look for extra large cookie sheets and didn't have much joy . It was cheaper for me to go to a place that works with granite and get a piece for free.

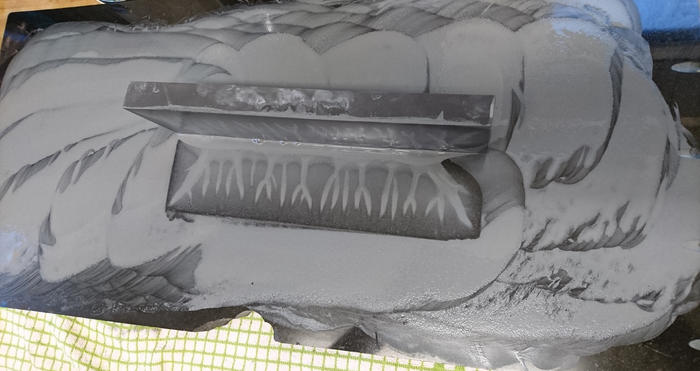

Yesterday I got a large piece of very hard granite from some helpful guys and spent over 2 hours lapping one of my Surgical blacks.

The marble I had used previously was a waste of effort leaving my stones far from flat.

After hours of lapping last night and most of that time was spent on the 60 grit, the granite has lost its polished surface but still seems nice and flat.

This weekend I will do the Translucent.. I'm making my way towards that Gok 20

-

07-02-2019, 07:33 PM #34Senior Member

- Join Date

- Apr 2012

- Location

- Diamond Bar, CA

- Posts

- 6,553

Thanked: 3215

Here is an interesting video about Precision Ground stones by Rob Renz, that demonstrates Diamond grinding a pair of India stones the results are similar to what we are trying to achieve by burnishing Ark stones.

While a pair of machinist precision ground flat stone are used for a completely different purpose, removing burrs from machined surfaces, they are $15-20 Silicone Carbide/ India Aluminum Oxide stones, 150 & 400 grit, capable of producing a near mirror finish on steel, because of how they are finished ground.

About half-way though the video Rob demonstrates the stria pattern the stones produce, out of the box, then machines them flat with a diamond wheel on a surface grinder.

The Precision Ground stones from Precision Instruments sell for about $500 a pair.

Burnishing does much the same thing on a lapped hard Ark stone, as grinding on a surface grinder, though with much less precision and flatness. Which is to flatten the grit. It is impressive the finish he is able to get from a 400 grit stone.

It would be interesting to surface grind a Black or Translucent stone with a diamond wheel, to see what kind of surface and edge it can produce.

()

-

The Following User Says Thank You to Euclid440 For This Useful Post:

ScoutHikerDad (07-02-2019)

-

07-02-2019, 07:52 PM #35The First Cut is the Deepest!

- Join Date

- Feb 2010

- Location

- Upper Middle Slobovia NY

- Posts

- 2,736

Thanked: 480

Oh, and go to the local postal depot with your stone, and ask them nicely to put it on the scale to weigh it. They will (normally) be more than happy to, as they are asked often for such services so people can determine shipping charges. Postal scales will provide a close and accurate weight you can use to determine density. When I did mine, I used a vernier caliper for the dimension measurement, as I didnt have a 6" micrometer available for the utmost accuracy. But as has been said elsewhere..."we aint building a rocketship here" ��

-

07-03-2019, 04:57 AM #36

-

07-03-2019, 03:06 PM #37

There is a formula for determining the specific gravity of a stone using its volume and weight, Joshua. I don't have it handy and have never messed with it; my well-burnished arks give up glorious edges, which is all I care about. But the idea is that, due to the unique nature of how these ultra-hard novaculite stones polish steel edges, the more dense stones (true hard arks, surgical blacks, translucents) have a higher SG. I believe that the usual claim is that these fine finishing grades are generally in the 2.5 to 2.75ish SG range.

When you're too tired to lift your arms any more from flattening those parking lots you have acquired, here is another rabbit hole to fall down on the issue: http://https://sharprazorpalace.com/...sas-stone.htmlThere are many roads to sharp.

-

07-03-2019, 04:15 PM #38

Cheers, I will have a butchers when I get home.

-

07-03-2019, 05:02 PM #39

You may also have already discovered Dan's website; here is their page on stone grades and related SG numbers: https://www.danswhetstone.com/inform...ne-grades-101/They are considered some of the world's foremost experts on Arkansas novaculite, as that is their family business. We have even had members make a pilgrimage to their site (which I wouldn't mind doing if I didn't have to go to Arkansas to do it-maybe on my next Western trip).

There are many roads to sharp.

-

07-08-2019, 09:13 PM #40Senior Member

- Join Date

- Dec 2014

- Location

- Virginia, USA

- Posts

- 2,224

Thanked: 481

Mine lives in it's wooden box and rarely sees the light of day. When I DO break it out, I literally use about half the stone. Honestly most of my 8" x 3" bench stones I only use about the center 6 inches of. I can't recall the dimensions of my other huge-ass Arkie, I want to say 10 x 2, but it never leaves it's box either. My 6" x 2" stone is my go-to.

I don't envy anyone in the process of lapping and surfacing a 12" x 3" Arkie. I've done it once, I'll pass on ever doing it again.

125Likes

125Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote