Results 1 to 9 of 9

24Likes

24Likes

Thread: SYNTHETIC STONE LAPPING 101

-

03-23-2020, 10:28 PM #1Senior Member

- Join Date

- Apr 2012

- Location

- Diamond Bar, CA

- Posts

- 6,553

Thanked: 3215 SYNTHETIC STONE LAPPING 101

SYNTHETIC STONE LAPPING 101

Synthetic Stone Lapping 101

So, your edges are not what they once were, nothing has change in the stones, but something has in the edges.

First, look at your stones when you have a honing issue. Are they smooth and flat? Maybe, maybe not as flat and smooth as you think.

Ok, letís check. First get a diamond plate in the 300-400 grit range or lower. Chef Knives to Go has a great 140 grit lapping plate for $30, money well spent if you do a lot of lapping. Low grit plates work faster, but you can lap easily with ANY 300-400 plate. They all work, and all are about the same flatness.

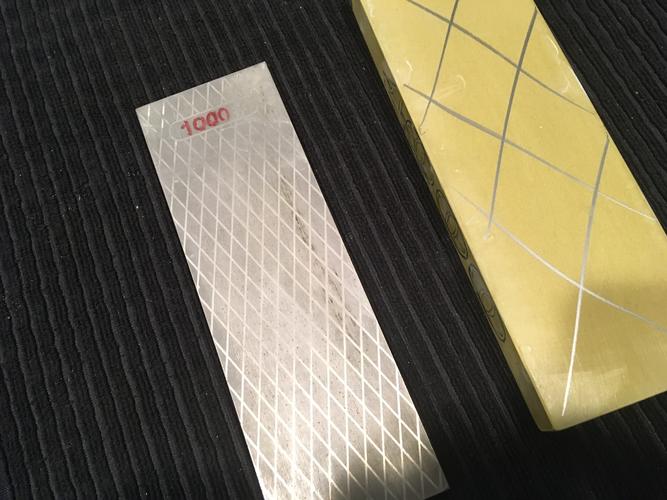

For this experiment I will use a CKTG 400/1000 grit plate on a 4k Nubatama stone, because most will be using a 300-400 plate.

Dead flat is not that important, and even if you do get a stone dead flat, it will quickly go out of DEAD flat with the first honing.

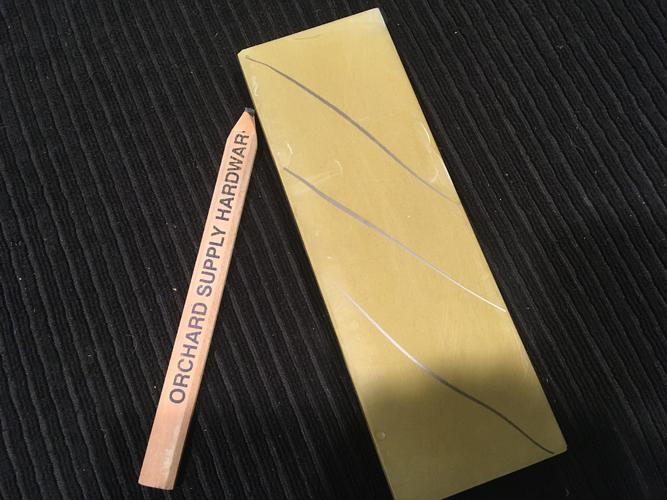

Mark a grid on your stone with a no. 2 pencil, I like flat carpenter pencils, about 25 cents from any hardware. Mark 3 grid lines from corner to middle, opposite corner to middle and one between the two. Do the same in the opposite direction, so you end up with a 1inch grid pattern.

Photo 1&2

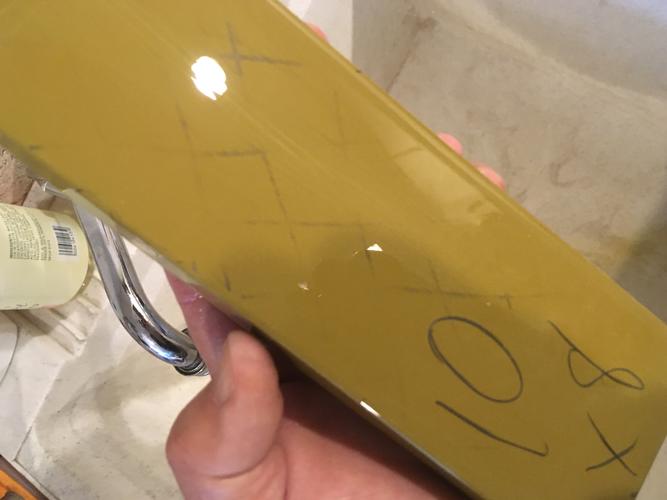

Under running water, just a little or under a pond of water, do 10 laps from end to end. Stop and look at where the marks are not removed, most likely you will have low spots in the center of the stone and the middle between the ends. The center is where the tip is worked and the middle is where most folks hone, (pressure). Photo 3, 10 laps.

If you watch honing videos, you will see most folks hone with the middle 4 inches of an 8-inch stone.

Lap until 50% of the grid marks are removed, then spin the stone 180 degrees.

DO NOT use added pressure. Adding pressure loads up/clogs the diamonds and will rip them from the plate. Use lite pressure under running water and occasionally run the plate face under running water or if using a pond, scrub the plate face with your fingers under water.

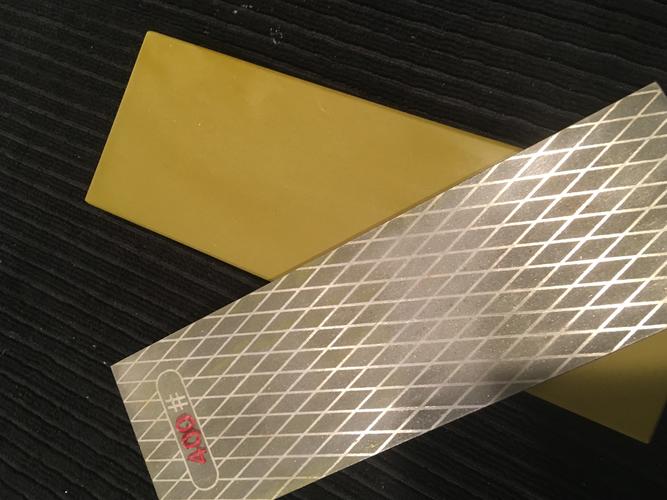

Once 90% of the grid marks are removed, re-grid mark the stone, Bevel the edges and corners about a 1/8th inch bevel. Most of the material that will need to be removed will be at the edges, beveling will quickly remove the highest material and prevent the edges from chipping. Photos 9&10

Re-lap under running water, do 10 laps and check again where the low spots are. Spin the stone when 50% of the grid is removed.

Continue to grid and lap until you can remove 90-100% of fresh grid marks in 10 lite laps or less.

It took me about 30 laps to remove the grid the first time and 9 courses of about 20-14 laps each. On the 9th course, most of the grid was removed in 10 laps. Photo7 is the 8th course, 9 and 10 were improve over photo 7 almost all grid was removed by lap 10.

Do not be tempted to use more pressure or short cut the process, stop early, thinking because you removed all the grid with 30 laps, the plate is flat. Use lots of water and let the diamonds do the work.

If your stone is way out of flat or super hard and not making progress, e.g. SG20ís are harder than Chinese Algebra. Get a sheet of 60 or 120 grit wet and dry and any flat surface, I use a steel cookie sheet from the dollar store on a plastic cutting board in the bottom of the sink and use the same process of marking and lapping until flat, then smooth and finish smooth with a 300-400 plate. It will take you several sessions to get to flat.

Again, donít use too much pressure, you will rip the grit from the paper.

For your final grids, mark as described above but add lines between each line, so you have about a1/2-inch grid pattern. Photos 4,5, &6.

I took a lot more photo, but because my hands were wet, most of them were short videos. I marked the number of laps and how many courses on the corner. I switched to the finer Ĺ in grid about halfway, because I had a low spot on one side near the middle and I wanted to track it.

The whole lapping process took about 20 minutes, but most of the time was stopping to dry my hands and take a photo. It should take you 10-15 minutes total, but it takes what it takes.

The bottom line is, you can not grid a stone and remove the grid once or twice and get a stone flat. Slurry will build up, even under running water and you may think you have lapped the stone flat, but really the slurry is removing the pencil grid and the stone is not close to flat.

Once 95-100% the grid was removed in 10 laps, I re-gridded the stone and repeated the process and one more time to make sure. A total of 10 grid and lapping sessions.

Now hone, see if your edges improve. As a stone wears from honing, rough spots develop, (the low areas). As the edges wear those rough spots hit the honed smooth edge with each stroke and impact the edge leaving rough spots on the edge. It can be almost self-defeating.

The goal is a smooth stone surface, flattening the stone face leaves a smooth surface. If you surface your stone frequently you can minimize dishing, but even then, a thorough lapping is a good idea, and eye opening.

-

The Following 10 Users Say Thank You to Euclid440 For This Useful Post:

AlanQ (03-24-2020), DZEC (03-24-2020), Gasman (03-24-2020), Geezer (03-24-2020), JBHoren (04-23-2020), lloydw (03-24-2020), markbignosekelly (03-23-2020), MichaelPz (03-24-2020), ScoutHikerDad (03-24-2020), sharptonn (03-24-2020)

-

03-23-2020, 11:53 PM #2Senior Member

- Join Date

- Dec 2012

- Location

- Egham, a little town just outside London.

- Posts

- 3,849

- Blog Entries

- 2

Thanked: 1082

Thank you, nice write up. Do you soak your hones first before lapping? I tend to soak a thirsty synthetic prior to lapping, just as I would prior to honing. I'd never bother soaking my Gok 20 though.

-

03-24-2020, 12:08 AM #3

I dont think you could get a gok20 to suck up water if your life depended on it. Damn things are super hard!

Nice write-up Marty. Im sure it will help a few new to this magic we call honing.It's just Sharpening, right?

Jerry...

-

03-24-2020, 12:39 AM #4Senior Member

- Join Date

- Apr 2012

- Location

- Diamond Bar, CA

- Posts

- 6,553

Thanked: 3215

No, I don’t soak it is under running water almost the whole time, so it gets plenty wet. A King 1k, I would soak for a few minutes.

One other thing to look for is the feel.

You will feel the diamond plate stick to the stone. I suspect, it glides over the valleys and stick to the high spots. As the stone flattens, the feel gets smoother until there is no more grabbing, and the face is smooth.

I suspect that a lot of issues that new honers have may be directly related to the quality of lapping.

-

03-24-2020, 02:18 PM #5Senior Member

- Join Date

- Apr 2012

- Location

- Diamond Bar, CA

- Posts

- 6,553

Thanked: 3215

If you want to prevent the slurry from going down your drain, or to collect the slurry powder, get a large tub and lap over the tub with running water running on the stone and plate into the tub.

The tub will fill with water, but the slurry is heavy enough most will fall to the bottom. You may have to stop occasionally and let it settle then pour off most of the water, then the slurry into another container.

Pour off the water and pour the remaining slurry onto a clean cookie sheet and set in the sun on warm cement. It will dry in a couple hours and you can harvest the powder. Make sure to mark the container or Zip lock bag and use a clean tub to catch the slurry so it is not contaminated.

Years ago, I saved a bunch of slurry from different natural stones and experimented pasting sailcloth and Pellon strops. You do not need to collect a lot as you can paste with less than a ľ teaspoon. It can be interesting, mixing slurry powder. If experimenting, paste cardboard.

It also keeps it out of the pipes, though I have lapped hundreds of stones and never had an issue with my pipes, I do make sure to flush with lots of running water when done.Last edited by Euclid440; 03-24-2020 at 07:37 PM.

-

03-24-2020, 06:51 PM #6Member

- Join Date

- Dec 2019

- Location

- Fl

- Posts

- 40

Thanked: 7

I find lapping after honing tends to be the most efficient method for myself.

The stoneís already wet, in some cases softer, and ready for lapping. Said stone is then ready for honing next time you need it.

This method, however falls flat on its face if your in a hurry to get a quick edge.

-

03-24-2020, 07:43 PM #7Senior Member

- Join Date

- Sep 2015

- Location

- Boise, Idaho

- Posts

- 315

Thanked: 38

A question I have never seen answered: I have a Nanniwa 12k and Vermio for finishing. I touch up my razor on a 7-8 week interval; maybe 10-20 xstrokes on the 12k, if I think it's needed, and 100 xstrokes on the Vermio. Light finish strokes. How often should I need to relap the stones? Yearly? If someone takes the time to lap a hard ark, and then burnish it, shouldn't it last a lifetime for a self-only honer? More than one question I know... Last, since I don't have a hard ark, is my Vermio of similar hardness? Will it ever need to be relapped?

I don't post much but am always here listening. Thanks.

-

03-24-2020, 07:48 PM #8Senior Member

- Join Date

- Apr 2012

- Location

- Diamond Bar, CA

- Posts

- 6,553

Thanked: 3215

The stone in the post is a Nubatama 4k, a fast, smooth cutting 4k. It is lapped before each use and before the finish strokes on the stone. So, it is lapped twice during each use, but it is not grid marked each time and lapped .

When I grid marked it and lapped it 10 laps, I was surprised how out of flat it was. After removing all the grid marks, it was still not flat.

It took 10 gridding and lapping sessions to get it flat and smooth, so the grid would come off completely in 10 lite laps.

That is the point of the thread.

Your stones may not be as flat as you think. I only tested my 8k when I had an issue and was no longer getting the finish off it that I once was. That is what started me looking at all my stones.

So, give your stone 10 lite laps, if 90-95% of the grid does not come off, your stone is no longer flat and smooth.

-

04-23-2020, 05:13 AM #9

I have noticed that when lapping, it sticks to the high spots but as it is getting flatter, it glides smoothly over the lapping plate. I just lapped my GMN-200 20k & it was taking forever so I tried some Dawn dishwashing soap on it and it felt like it was cutting better. I started getting somewhere then and I had it submerged just enough to barely have water on top of the lap which helped the soap stay on the rock longer. I was able to finish it quicker after applying the Dawn a few times. I used my DMT 8" Dia-Flat 95 Lapping Plate on this one. If I want a finer finish I can now use my Shapton or Atoma. With those ya have to take many breaks from it. I lap my stones after honing each razor so they are ready for next use. I lapped my 20k because it had sat on the rubber base so long it had a large purplish/black stain on it & I didn't like it. It had to be the rubber base.

Last edited by engine46; 04-23-2020 at 07:52 PM.

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote