Results 21 to 29 of 29

Thread: Jnat bevel setter?

-

12-31-2009, 04:46 PM #21

Ok, I have read those threads and realized I have no clue (my kids know this already) where I read that the Iyoto dishes easily.

OTOH, I have done some reading on various sword polishing sites including "3 Raven's Metalcraft" which has this in his blog:

What is Iyoto…

By 3ravensmetalcraft Leave a Comment

Categories: Uncategorized

Tags: Toishi

Iyoto stone comes from the area around Iyo in the Ehime Prefecture in Japan. Records show that iyomeshime has been used for polishing blades since the Nara Period, but there appears to be some anecdotal evidence that it was in use nearly 400 years earlier. (The Nara Period is around 700AD, so the recorded history of Iyoto stone spans over 1300 years!)

The mines were closed for a period of about 30 years in the last century, but were reopened and new material is slowly working into the marketplace.

Some varieties of Iyoto, of which there are several, were used as the final stone in sword polishing for about 500 years, until the Honyama mines around Kyoto became active. In the present day, and I hope someone will correct me if I’m wrong, Iyoto stones are part of the final series of stones foundation polishing (EDIT: looks like they might be part of the chu-nagura as well as the koma nagura).

Like all of the Japanese natural polishing stones, it is very difficult to pin down what the grit size is in order to give an accurate description of the material. The natural world didn’t provide uniform grains when these sedimentary rocks formed, unlike modern, manufactured stones that are composed of finely graded abrasives. In the case of Iyoto, the best that can be done is to provide a range of grit sizes that might be present in any given stone.

That being said, for comparison’s sake, Iyoto is somewhere between 800 grit (JIS) and 1500 grit.

The curve ball is that there are Iyoto that push into the 3000 range. For another trick pitch on top of the curve ball, that 3000 grit might come from the stone you bought as an 800 and have been using for the past few years.

The abrasive agent in Japanese water stones doesn’t break down uniformly, and the cementing particles in the lithic structure aren’t uniform either. Call it “The Miracle of Nature” or “God has a sense of humor,” but this is part of the reason why these stones are so wonderful and mysterious… You never know if the so-so rock you bought might not turn out to be the treasure of your collection as time goes on.

Many people who are familiar with synthetic or natural water stones know about the Nagura stone. It is a stone used to raise up the abrasive on fine grit water stones. It provides, with water, a thick “milk” on the surface of your stone that lubricates and polishes as you use it.

Iyoto can be used as Nagura, as well as for polishing blades. I have found that Iyoto (white and Arinoki) make a thicker paste than Nagura, and polish even better.

I just received a small shipment of Narutaki and Uchigumori stone, and I absolutely can’t wait to see what my Iyoto slurry stones will add to polishing with such fine grained stones!

2009 September « Three Ravens Metalcraft

-

The Following User Says Thank You to Pyment For This Useful Post:

Jasongreat (01-01-2010)

-

12-31-2009, 05:15 PM #22Hones/Honing/Master Barber

- Join Date

- Aug 2009

- Location

- Waynesboro, PA

- Posts

- 997

- Blog Entries

- 6

Thanked: 199

I know this is kinda off topic, but anyone ever come across ANY natural bevel setter? Doesn't have to be Jnat. Was just curious if anyone found a decent one that would work for razors

Like a poster above, I am curious about the white amakusa...maybe it will work better than the red

Maybe when I get some money, I'll try it unless someone beats me to it

-

12-31-2009, 05:36 PM #23

Nice quote on the source of Iyo stones or Iyoto. Iyo is on the island of Shikokyu near the town of Matsuyama, a beautiful town with tons of history and host (youtube it) of the Matsuyama mikoshi samuri battle festival. Matsuyama is also known for their porcelain ware. In the mountians behind Matsuyama and Iyo are the mines that produce the raw materials for porcelain, kaolin. The stratas of kaolin and those stratas producing material for Iyo sharpening stones are very similar and close together, not only in Iyo but in other areas too of Japan. This is why every once in a while you will hear of a chef who sharpens his knives on the back rims of porcelain dinner plates.

Alx

-

12-31-2009, 06:05 PM #24Senior Member

- Join Date

- Aug 2006

- Posts

- 882

Thanked: 108

I'm getting surprising results from my Turkey stone, but am still to early in my experiments to say anything definitive. I will say this: their reputation for brittleness is earned. Mine is two inches thick and two inches wide. Of its four 6" x 2" surfaces, only one is crack-free.

-

12-31-2009, 06:13 PM #25

Hi Pyment, heh that was 5 pages and didnt have time to read t this morning myself. I'll get to it later. Maybe it was japanese tools forum where we had a brief discussion on coarse nats. It was not the Iyo that dished easily. All stones dish so where's the issue is what I think.

-

12-31-2009, 07:31 PM #26

Kevint,

then the impression is that the Iyo dish no more than similar grit stones?

The other question is, do you get an Iyo that is all white for consistency or with all the colors because they look cool?

(I believe looking cool to be an important function of natural stones).

-

12-31-2009, 10:50 PM #27

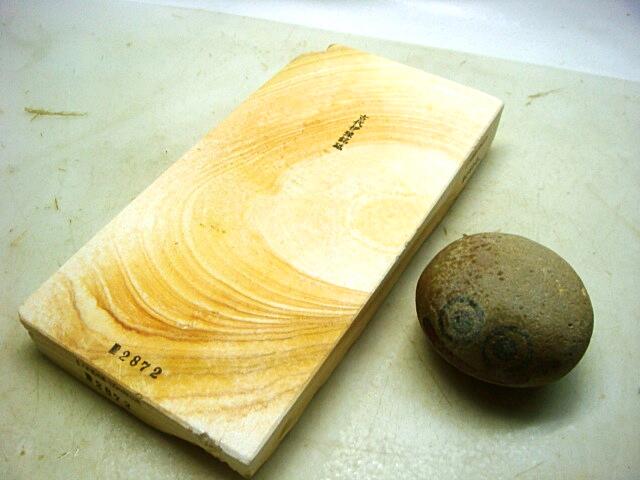

py I don't have a lot of them. It is for sure harder than aoto. harder than norton 220.

The woody ones are cool looking, perhaps fetching a premium for that reason.

I didnt price them; i just bought a cheap one on ebay, i have nothing to compare it to. I like it though and should probably pursue some stock for future use. a nice big chunk.

-

01-01-2010, 02:01 AM #28Rookie

- Join Date

- Nov 2009

- Location

- Delta, Utah

- Posts

- 372

Thanked: 96

Thanks to everyone who has posted so far, each and every point has given me something to think about. I am sure the smart move would be to follow gugi's advice and get more experience under my belt before venturing beyond my limits, but I always let my curiosity get the best of me. I do have a couple pro-honed razors to compare edges against, one by Lynn and one by cedarfurnitureman off ebay. I can see IanS view of faster is better and going the DMT route but I am looking more for feel than speed, I am not too impressed with the feel of my nortons while honing. I wish I would of started with gugi's advice since I bought a Jnat finisher that feels so much better to hone on I find myself leaving the nortons behind before I should, and my finisher(if it even is one) does have its problems, which I could of waited to tackle until I had more experience to draw from. That though is why I love this forum so much, there is a vast field of experience to inquire about. Memorael stated that the naniwa's have a great feel to them, since that seems to be the main reason I am looking for a different bevel setter maybe that would be the solution that would work for me. It is just that I seem to have too much free time right now, I read through the forums then hang out on ebay and other sites looking for stuff to buy, I cant remember whos sig line says it but it says newbies stay away from ebay, I always seem to find good advice only after the bug has hit me that the advice would have prevented. Oh well, live and learn. Kevint, if I remember right you said your iyo is amost pure white and harder than aoto. I think 330mates description said that the pure white are the least abrasive and the grainy ones are more abrasive. Have you tried the grainy structured iyo, do they seem to follow the grit pattern as 330mate explains it?

Thanks again for all the help.

-Jason

-

01-01-2010, 03:43 AM #29

that's good to know Jason; i had not seen that. I have been using it today just a short time ago. It is certainly on the slow side.

I've never found a reason to doubt Nakaoka's knowledge of his wares. I just accept the fact that I am not getting a hidden gem.

It has been cut up for nagura and scrub stones. One of the things i've changed in my honing is to use a scrub stone to keep the surface clean after an initial lapping on dia,plate.

I don't want to sound like I wouldn't wish it more aggressive if possible. Nevertheless with an aoto and suita I can do most anything but take out a chip, but those two are not the best pair for lapping each other. Add the Iyo in there and they can all be kept pretty flat.

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote