Results 21 to 30 of 38

Thread: Barber Hone Lapping

-

03-02-2011, 06:23 AM #21illegitimum non carborundum

- Join Date

- Jan 2008

- Location

- Rochester, MN

- Posts

- 11,552

- Blog Entries

- 1

Thanked: 3795

-

The Following User Says Thank You to Utopian For This Useful Post:

Zorro (03-02-2011)

-

03-02-2011, 06:43 AM #22

-

03-02-2011, 07:15 AM #23

+1 on clear water or perhaps a bit of lather.

Since barber hones do not develop a slurry (unless abused) I stumbled

on using a white fluoride toothpaste to "wake up the surface". Toothpaste

abrasives are mostly softer than steel so they mostly clean the surface

of the hone.

Having said this one of the ideal conditions of many barber hones is glazed

and shining. As the barber hone glazes over it hones finer and finer which

is often a good thing (up to the point where it no longer hones).

If you do sand or DMT flatten a barber hone know that the surface will need

some time or work to calm down. The surface will pick up a texture that reflects

the coarse material last used to lap it. It will take finer papers and perhaps time

to calm it down.

Different hones are made in different ways. Since they were made in vast numbers

some but not all have a middle of more common brick mud and have a thin slip surface

of carefully classified fine material. Only the carefully classified fine material is

razor hone quality so caution with an aggressive DMT is in oder.

And yes if the surface has a divot that causes a razor to jump or catch it

needs to be relieved. As for divots some barber hones are made with

dimples to hold water or whatever. So a divot that the blade glides over

is a do not care.

-

The Following 4 Users Say Thank You to niftyshaving For This Useful Post:

ezpz (03-03-2011), hope (05-13-2013), randydance062449 (03-02-2011), Zorro (03-02-2011)

-

03-03-2011, 11:24 PM #24

i appreciate niftys comments about surface texture.. my swaty became smoother after lapping on a worn 325.

-

01-11-2012, 05:51 AM #25Junior Member

- Join Date

- Nov 2011

- Posts

- 2

Thanked: 0

-

01-12-2012, 07:34 PM #26

Can you feel it if you take a bit of 500 to 1000 grit 3M wet dry

and worry the area of the scratch and relieve the edges of

the scratch.

Some but not all barber hones have a very different

center with a fine honing slip on the surface. Lapping

with a coarse DMT might quickly wash the good bits

down the drain. The problem is that you are good to

go up to the point that the good bits are gone -- there

is no warning... you have a good barber hone, lap it and the

inside is exposed and you have a bit of brick full of sand

and generally not razor friendly stuff.

Which side has the scratch, becomes the next question.

You can hone on the opposite side in most cases.

-

The Following User Says Thank You to niftyshaving For This Useful Post:

hope (05-13-2013)

-

01-12-2012, 08:01 PM #27Hones & Honing

- Join Date

- May 2005

- Location

- Saint Paul, Minnesota, United States

- Posts

- 8,023

- Blog Entries

- 1

Thanked: 2209

-

01-12-2012, 09:37 PM #28Just a guy with free time.

- Join Date

- Oct 2011

- Location

- Mid state Illinois

- Posts

- 1,448

Thanked: 247

Ok, I think nobody mentioned it, so I'll put it in here. You can lap a barber hone on another barber hone. Been an approved method since at least 1895, when some guy with thirty years experience put it in a book. Yours is already done now, but just an FYI. I did it myself, and while I can't comment on its efficacy as compared to a DMT, it's much faster and more effective than using sandpaper IMHO.

-

02-04-2012, 07:40 PM #29

Glad to see this thread.

I am looking to buy a hone off ebay and am anticipating the need to dress the surface as I see chips and so forth out of nearly all the hone edges. I had assumed it was standard practice to "clean them up" a bit.

-

08-28-2013, 03:45 AM #30Str8Faced Gent.

- Join Date

- Aug 2013

- Location

- Orangeville, Ontario

- Posts

- 8,456

- Blog Entries

- 1

Thanked: 4207

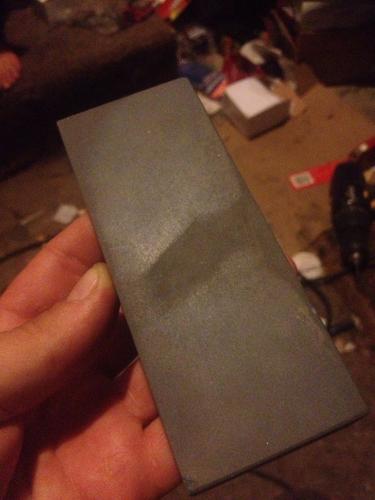

Hi all. I picked up a NOS carborundum no152 barber hone on ebay that seemed quite flat and in perfect condition..

I soaked it in RO water and have been using it for a week now, both with lather and without, but it has developed a rough spot in the middle, or the outer edges have glazed, not sure which really. All I know is you can feel it when the razor passes over the area while honing and I'm curious as to why and whether lapping is advised or not. Along the edge of the darker gray side it seems the roughness of the area in the middle of the face, but as the pics show, there is a much smoother areas on ether side that definately look glazed.

So to lap or not to lap? I always assumed the stone was the surface grit all the way through and I did start to work the surface a bit with a DMT 600, but now I'm not sure. Don't want to ruin it and the stone in one action.

Anyway, take a look and give me some ideas.

Thanks allLast edited by MikeB52; 08-28-2013 at 03:49 AM.

10Likes

10Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote