Results 31 to 38 of 38

Thread: Barber Hone Lapping

-

08-28-2013, 04:14 AM #31Hones & Honing

- Join Date

- May 2005

- Location

- Saint Paul, Minnesota, United States

- Posts

- 8,023

- Blog Entries

- 1

Thanked: 2209

May I suggest you start a new thread and try for some pics without the shadow in the middle of the hone?

IMHO the carborundum hones are of uniform grit all the way thru. There is no danger in lapping them but you will find it a very slow process.

You do need to determine if the center is actually coarser then the center of the hone at the ends. The pics just do not give enough info to help. try to meet up with someone local to help you answer this.

use this search screen to find someone in your area...........

http://straightrazorpalace.com/memberlist.php?do=searchRandolph Tuttle, a SRP Mentor for residents of Minnesota & western Wisconsin

-

08-28-2013, 01:03 PM #32Str8Faced Gent.

- Join Date

- Aug 2013

- Location

- Orangeville, Ontario

- Posts

- 8,442

- Blog Entries

- 1

Thanked: 4206

Thanks for the reply Randy. Wasn't sure if this should reside within that barber hone thread or not.

I will start a new thread as suggested as I will surely have lots of thoughts and questions on the razor honing craft as I get further adept at it.

Regarding the shadow across the middle of the hone in the pics, that is actually the area of roughness I am referring too. That shadow is on the hone surface and is a rougher feel than the areas adjacent it on the face ends.

I'm going to purchase a few sheets of 240-320 wet sanding paper to work the surface with on the weekend.

Like I said, there was no mark on it when I received it and I haven't used it more than a few times. The box indicates it is quite an old stone but was new old stock and showed no signs of wear before I received it.

I did leave it and my 12000k stone in a container of reverse osmosis filtered water for the week continuously and I also tried lather on the stone as the original instructions suggested. That's pretty much the history of my trials thus far.

Thanks again.

-

08-28-2013, 05:54 PM #33Hones & Honing

- Join Date

- May 2005

- Location

- Saint Paul, Minnesota, United States

- Posts

- 8,023

- Blog Entries

- 1

Thanked: 2209

I just called a friend with a lot of experience with the Carborundum hones, Utopian.

he feels that they are solid all the way through so it would be safe to lap it. He made a distinction between the 101, 101A, 102 & 103 which are marked on the box as a razor hone. Is yours? If not then it is a sharpening stone and not as suitable for razors.

I asked about porousity and he said that the 101-2-3 are not porous but some of the others are. It sounds to me like yours is porous because it has glazed along the edges, probably from the shaving lather. Since the glazing is only along the sides it suggests that the sides are " high" and the center is "dished". This means the hone needs to be lapped flat. I suspect that the roughness and discoloration in the center is from a buildup of swarf coming from the edges when you hone.

So....I don't think you have a razor hone, just a sharpening hone (knives). I think it needs to be lapped flat to be useful.

Just my 2¢

Going out of town for a few days so I will not be able to comment further until I get back.

Good luckRandolph Tuttle, a SRP Mentor for residents of Minnesota & western Wisconsin

-

08-28-2013, 06:16 PM #34

+1....

That is not a razor hone in my experience. The commonly accepted carborundum razor hones are the models 101, 101A, 102, 103, 104, 105 and 106. Also the model 118 is a razor hone but in my experience not as 'fine' as the lower numbers. I have all of them, and IMO they are very fine razor hones...vastly under-appreciated by many. My favorite is the #102. It is a very hard and very fine Barber hone and will put a nice 'touch-up' edge on a razor. If you can find any of these model #'s you won't be disappointed.

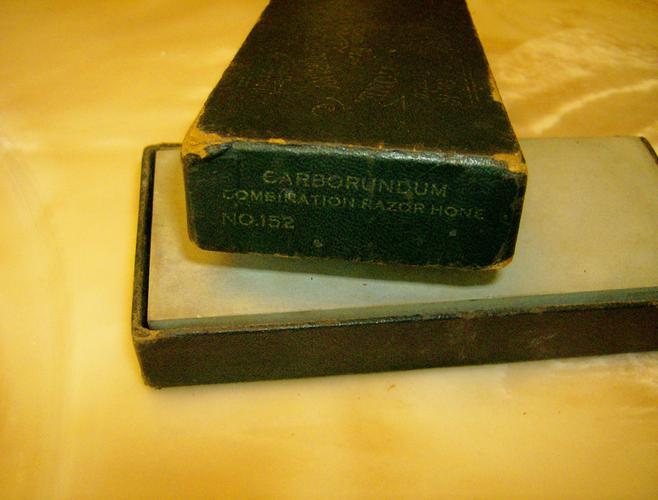

Here is a pic (courtesy of Utopian from a prior thread) of these hones:

-

The Following User Says Thank You to Wolfpack34 For This Useful Post:

randydance062449 (09-06-2013)

-

08-29-2013, 12:14 AM #35Str8Faced Gent.

- Join Date

- Aug 2013

- Location

- Orangeville, Ontario

- Posts

- 8,442

- Blog Entries

- 1

Thanked: 4206

Thanks for the replies all.

Would love to pull this string into a new thread but it works in here too I hope.

Mine is a carborundum 152 and from what it says on the box it was designated as a razor hone.

Hard to get a pic that does it justice and if the glazing is from the lather than maybe it just didn't stick it the middle area due to contamination on the stone from the years in storage.

I will try to lap it on some 320 grit wet paper and see if that areas grows or shrinks with the efforts. Will lay out a pencil line grid and define the area with pencil as well.

At the end of the day if I need to buy new honing stones and this antique 152 just becomes a collectible, not to bad based on some of the collections I've seen on here..

You mentors, veterans, and regulars really got stones, lol..

I just snagged a nice bundle on eBay with seven vintage assorted blades from three continents so I have lots of practice coming my way..

Thanks again all.

-

09-01-2013, 07:02 PM #36

Note well modern hones are head and shoulders better than almost all old school barber hones. Carborundum brand hones can be equal to the near 7k grit hones when lapped and clean. Old school tricks with lather, Vaseline can get results approaching a modern 11k hone.

If you lap it expect the barber hone to act a lot like the last thing you lapped it on for a while. Worry it smooth on flat scrap steel perhaps with the help of common white tooth paste.

An X pattern on a short hone tolerates a lot of dishing.

5 laps, strop shave test, See Lynn's video on honing with a barber hone.

-

09-02-2013, 03:09 PM #37Str8Faced Gent.

- Join Date

- Aug 2013

- Location

- Orangeville, Ontario

- Posts

- 8,442

- Blog Entries

- 1

Thanked: 4206

Morning. So I have lapped my old carbo 152 initially on 220 grit wet paper, then onto my dmt 600 in a pan of water that just covered the top surface.

Took 2 hours of circles and x's to remove the surface glazing and roughness detected.

The 220 went right dull in about 25 minutes, and I moved to the dmt with trepidation after reading on here all the folks that said they ruined their dmt's lapping their stones dry, hence why I tried the pan of water for constant flushing.

Well the results are in and it does feel much flatter for certain.

I used my learner asian blade on it and as cautioned, it did feel rougher grit initially, but rougher uniformly across the hone face.

The finer side of the hone seems to just slide across the dmt when I tried an initial lapping, even though there is evidence of it working. It just feels more slidy to the touch while lapping, not sure if that's cause I am dulling my dmt600 or cause of the grit on the stone.

Tried another honing on my vintage Boker Adonis after worrying the hone faces with my cheap asian blade and it shaves very smoothly now to my novice touch.

Cuts arm hairs at the surface easily and pops hairs mid height as well.

So I am pretty happy with the hones surface now.

Thanks for the help all. You were right that it takes a while and patience to wear these old barber hones smooth.

And while I'm happy with this stone as a starting point, and a great eBay buy at $30. I foresee some higher quality new stones in my future... As I acquire the touch and the assortment of razors that require different techniques, I see a collection abrewing,,hehehe.

-

09-06-2013, 02:04 AM #38Hones & Honing

- Join Date

- May 2005

- Location

- Saint Paul, Minnesota, United States

- Posts

- 8,023

- Blog Entries

- 1

Thanked: 2209

Just came back last nite.

Glad to see that you have followed thru with the tedious lapping and that your edges have improved.

You have been given correct advice by Wolfpack34. Utopian called me back and said the same thing as Wolfpack34. The Carborundum 101-3 series hones are a finer grade than the 152.

Good luck Randolph Tuttle, a SRP Mentor for residents of Minnesota & western Wisconsin

Randolph Tuttle, a SRP Mentor for residents of Minnesota & western Wisconsin

10Likes

10Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote