Results 1 to 10 of 34

Thread: Japanese natural hone help!!!

Hybrid View

-

08-17-2011, 04:27 PM #1

Bright

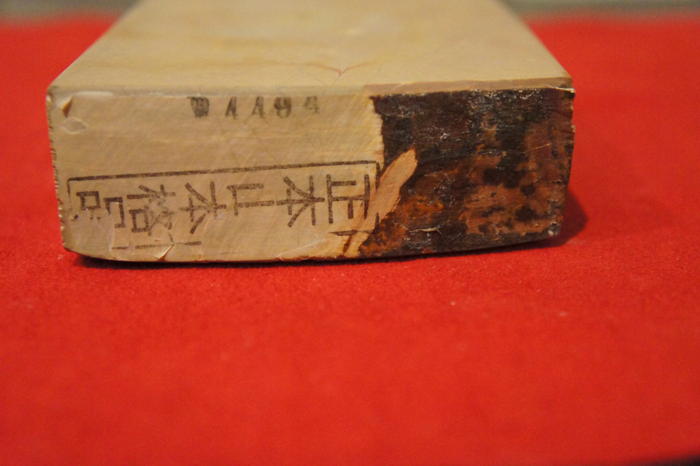

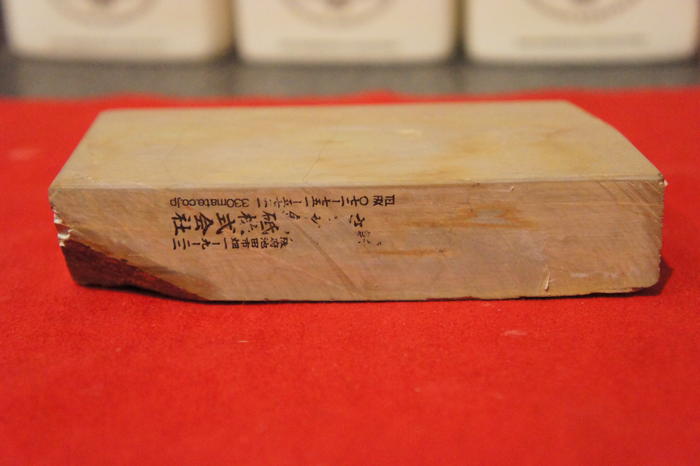

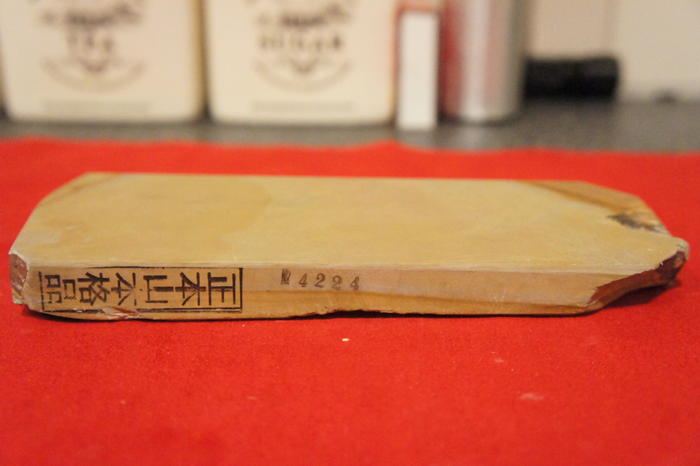

I would like to see a clear photo of the back of the stone if possible and from one side at least. The stones mined around Kyoto for sharpening are sedimentary formations that have been hardened by compression and indirect exposure to volcanic heat. The unique nature of sedimentary stone is this stratification or layering of material, and the miners are well aware of the attributes of following the natural stratified grain when prying out and wedging the distinct layers or strata free. The dozens of distinct stratafied layers within the mine are not blasted out or dug out with a shovel but are instead peeled away from each other with picks, bars and wedges. This is done carefully so that the pieces come out as large as possible and all the while following the grain of the stone and never against it.

Every time the stone gets picked up and handled by the miner it gets smaller, beginning within the mine where it is judged, tapped, sounded. And while any hard skin "kiwa" or softer fleshy stone is knocked off with a type of hatchet the grain is always followed. By the time the stone gets to the mine entrance it is half the size, and the trip down the mountainside finds the stone even more refined, shaped and smaller. Usually no sawing is done on the mountain side, only chisels and picks and hatchets are used.

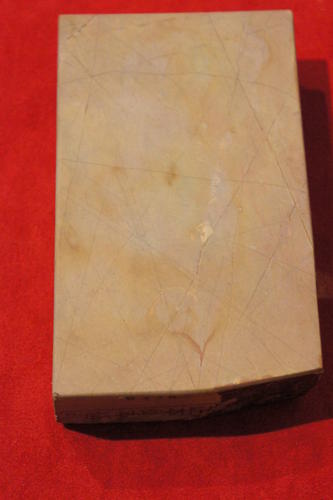

The stone you have if I am not mistaken was cut on all 6 sides by a saw, and instead of following the natural grain of the stone, it was instead mapped out and cut on the bias of the grain, like at an angle to the grain. Doing this exposes the stratification at its weakest, the end grain. And depending on the angles, the end grain will flake off at all kind of angles in little chips. The chips will look wedge shaped and somewhat flat, again depending on the angle.

Processing a stone in a manner like this is obviously going against the natural geometry, and was probably done in order to fashion and salvage the largest possible finished stone from an odd shaped piece of raw stock. In not taking into account the inherent qualities of the stratification the processor ended up with an inferior large product, where as he/she maybe could have ended up with a smaller superior product if the grain had been followed.

I am suggesting that if your stone was indeed cut on the bias then you will continue to have this flacking problem flare up from time to time. If the stone is cut on the bias the granular consistancy on the working surface of the stone will represent many different layers of compressed material sticking up as end grain, and thereby providing spotty and unpredictable sharpening qualities at best, and flacking at worst.

Su lines are not bad in and of themselves and are usually the result of an intrusion of water borne minerals transported as seepage at some time early in the stones formation. I have some stones in my collection with these tight fine lines that are epic finishers, but when coupled with a bias grain or converging lines these su lines can become liabilities. On the other hand if the stone was cut with the grain in mind then the su would be represented as an intrigual part of the overall homogeneous working surface.

The really great stones are homogeneous from side to side, end to end and front to back. Of course not even e-rays can see the center of the stone regarding granular make-up, core samples are out, but with some training and handling deductions can be made. All the above is in regards to consistancy, cutting qualities are a different matter. The actual cutting qualities of a stone can not be enhanced or mimicked. Someone might suggest that diamond dust or fairy dust from Tinkerbell can make a dynimite stone from a fake. If that is the case then you might just as well use a factory flattened ceramic tile from Home Depot with you magic dust rather than an imported natural no matter from which country.

If the stone was not that expensive you might keep it as a sample and a reminder. good luck. AlxLast edited by zib; 08-21-2011 at 04:22 PM.

-

-

08-17-2011, 04:53 PM #2

Thanks Alx, How is this?

-

08-17-2011, 05:15 PM #3

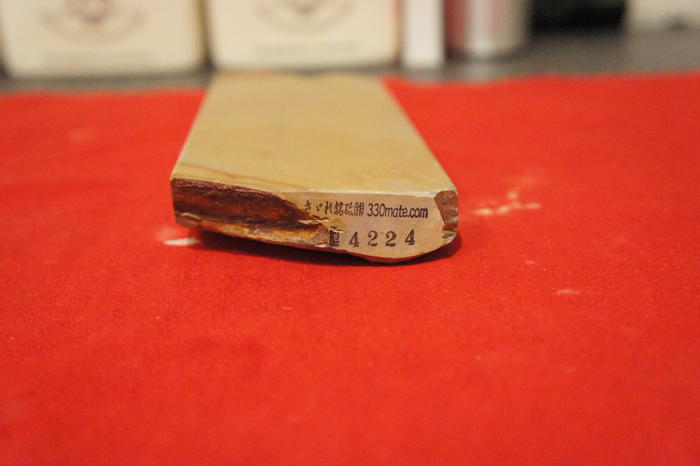

Could you also have a look at this one i got off the same seller? Thank Alx!

-

08-17-2011, 05:22 PM #4

They went cheap stone, that's for sure! I could have purchased a full shapton glass set for the same price. Or 2 of the cheaper stones \ 1 good stone from the site you provided. or 1 good stone from the site mainaman provided (maxim207's site).

But whats done is done and im not going to kick my self over it, and they seem to be doing what they are supposed to, for the moment. As said before i will use one of the two sites provided next time.

The second stone actually gives the best mirror finish out of all my stones, including my cheap, good, natural and synthetic. So i'm not disappointed with that one at all.. well not unless you tell me its cut wrong or something hehe

If you need any high definition shots of sections, zoomed shots of sections etc let me know and i will organize one.Last edited by Brighty83; 08-17-2011 at 05:30 PM.

-

08-17-2011, 07:29 PM #5

Excellent photos. The stone looks better than I thought, having the skin on the back is a good sign, and the sides too, but I can see the curved nature of the strata from the side with no skin. This is what I was talking about and I am pretty sure that from time to time the flaking may be an issue, hard to tell too far into the future. but good luck with it. Alx

-

The Following User Says Thank You to alx For This Useful Post:

Brighty83 (08-18-2011)

13Likes

13Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote