Results 1 to 10 of 14

Thread: Out of Shape Norton

-

12-18-2011, 02:10 AM #1

Out of Shape Norton

Out of Shape Norton

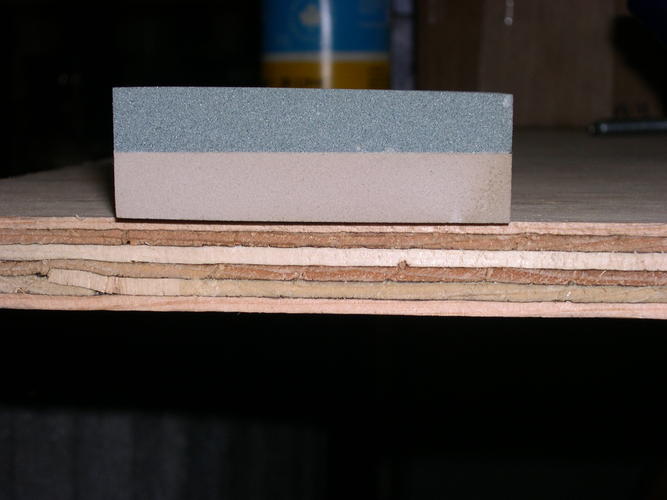

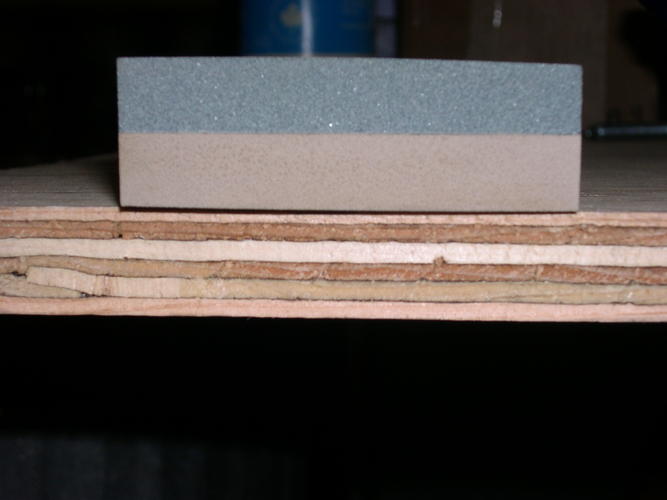

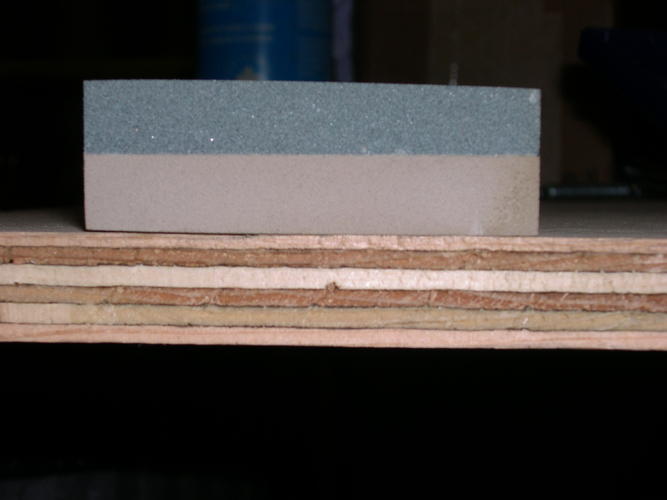

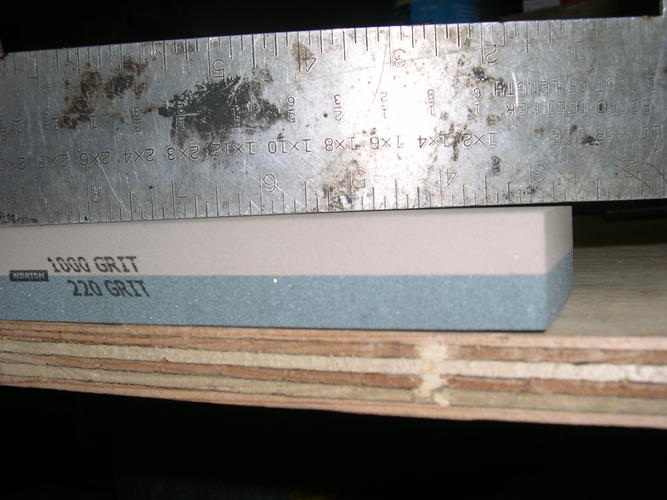

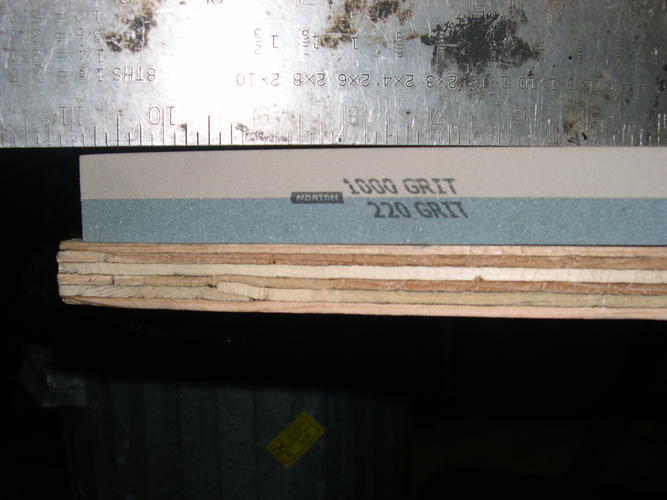

Has anyone else who purchased a Norton stone find that it is not flat? My 220/1k is off Xcorners. The 220 is quite a bit off, and the 1k a bit less, but opposite corners are sagged down. Not sure of the fact that they were made in Mexico has anything to do with it. The US made 4/8k seem to be right on, but I will have to look a bit closer. Here have a look

-

12-18-2011, 02:19 AM #2

Almost all hones need to be lapped out of the box. Sometimes you have to remove quite a bit of material to get it completely flat. It's just the nature of the beast.

-

12-18-2011, 02:22 AM #3

Did you purchase a Norton lapping stone or a DMT 325 when you purchased your Norton to flatten it?

That, as I understand it, is the usual procedure before using any waterstone, Norton included. Just to be safe, I would even lap your 4K/8K before using it."Age is an issue of mind over matter. If you don't mind, it doesn't matter." Mark Twain

-

12-18-2011, 03:21 AM #4

Yeah, I got the Norton lapping stone too. From what I have been reading, eventually I will need to lap it too. Thats alright, I got lots of sand paper at work

The worst with the 220, is that it is so pronounced. I will have to lap the sh!t out of it. As it sits now, it rocks from corner to corner, and that is with very little pressure. On the other hand, I will probably not use that side very much. But, my lapping stone will need a lapping by the time I am done. I think I will start at the top, and work down to 220. Thanks for the replies.

The worst with the 220, is that it is so pronounced. I will have to lap the sh!t out of it. As it sits now, it rocks from corner to corner, and that is with very little pressure. On the other hand, I will probably not use that side very much. But, my lapping stone will need a lapping by the time I am done. I think I will start at the top, and work down to 220. Thanks for the replies.

-

12-18-2011, 03:38 AM #5..mama I know we broke the rules...

- Join Date

- Feb 2010

- Location

- Toronto, Ontario, Canada

- Posts

- 2,895

- Blog Entries

- 8

Thanked: 993

My Norton 220, 1, 4, and 8 took quite a bit of lapping to secure a flat and lovely surface. I avoid the 220 at all costs, as it's way too abrasive and it drinks water like nobody's business. The 1k with a huge slurry is a much better restoration starter.

On the 4/8, I remember lapping about 1/8" off both grits to get to a nice smooth surface. I used the norton lapping plate, which is less than reliable as a truly "flat" surface. It took the brunt of the work, and then I finished the job with a glass plate and 3M wet/dry to 2k.

About six months later, I had saved enough money to purchase a DMT 325. It made a large difference in both 1) lapping time, and 2) stone feel. The DMT is a much true'r "flat" surface, and as the diamonds wear, the hone felt as though it became smoother.

My 4/8 is lovely, and as I recently posted, my 8K is my favourite stone to be on in the progression. I find a lot of joy when I get to move into that grit.

Lap away....lap, lap, lap away. Good luck!

-

12-18-2011, 08:18 AM #650 year str. shaver

- Join Date

- Aug 2008

- Location

- Pothole County, PA

- Posts

- 2,258

- Blog Entries

- 2

Thanked: 522

I have near 40 razor hones and I never received any that were that severely "out of flat".

Freshly manufactured hones nowadays should be finished on Blanchard type diamond bit grinders and should never be that much out of flat. I would contact Norton and lodge a complaint w/photos.

JerryJERRY

OOOPS! Pass the styptic please.

-

12-18-2011, 01:12 PM #7

I just received (yesterday) a Norton 4K stone which proudly wore a "Made In Italy" sticker which surprised me. I used the DMT325 to lap the hone. I was very happy to see that it did not take much work at all. I marked the stone with a pencil, lapped it under running water. Once the pencil marks were gone, I did it again. I would say it took no more than five minutes. Now, the Naniwa SS hones I also received took much more work. I lapped the 3K and 5K in about an hour and am still working on the 8K.

Just my 2 cents.“Two things are infinite: the universe and human stupidity; and I'm not sure about the universe.”

Albert Einstein

-

12-18-2011, 05:41 PM #8

I have never recieved a stone that was flat.

I have found that the first lap, done on a granite lapping plate with 220 grit Wet or Dry will take off that material fast, then I can take it to my DMT D8C and finish flattening. Do the checkerboard pattern with pencil and finish it on 1000 grit Wet or Dry to finish the surface.

That's what I do...

BTW I have Granite Flattening Slabs for sale on EBay for this very process.

I never freak if they are not flat. (Not like I have THAT many hones, probably around 25 or so now) Not a single one of them was perfectly flat when I recieved it.

My 2 cents!!!!

Mike-- Any day I get out of bed, and the first thing out of my mouth is not a groan, that's going to be a good day --

-

12-18-2011, 06:53 PM #9

-

12-21-2011, 10:38 PM #10

Well, it been a few days, and haven't heard anything from Norton Abrasives, but I did call Lee Valley. THey are going to get a courrier to pick up the 220/1k stone, and the guy that I was talking to said he didn't care much for the flattening stone. I told him that I even had to flatten the flattening stone. Anyway, he is going to take it back also. The sweet thing is is that he is going to get a courrier to come get the stones, and have a 1k shipped to me. Anyway, just wanted to spread some good cheer, seeing that it is Christmas..... .....Bah Humbug

PS: I just had to add, I heard back from Norton Abrasives, and they are going to send me a new 4k stone for my troubles. I am surprised, because that usually doesn't happen to me. So there you go. Sometimes it pays to complain..........er I mean point out flaws to a manufacturer.

Last edited by scaredstraight; 12-22-2011 at 01:34 AM.

3Likes

3Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote