Results 1 to 10 of 30

Thread: Did i ruin my barbers hone?

-

08-03-2012, 04:41 AM #1Member

- Join Date

- Jul 2012

- Posts

- 39

Thanked: 10 Did i ruin my barbers hone?

Did i ruin my barbers hone?

Hi guys...

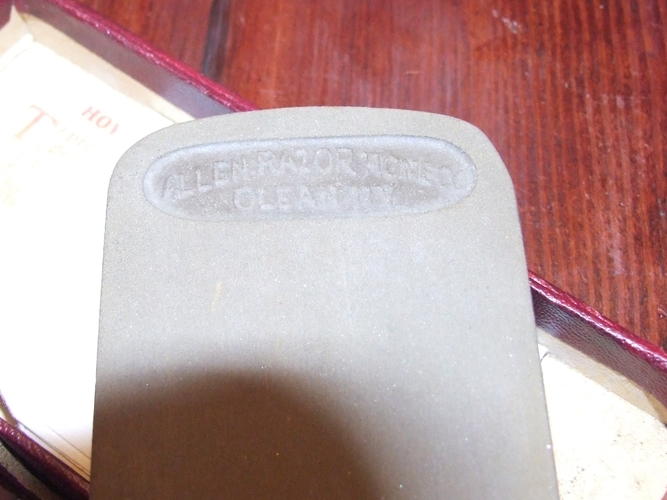

I got a combination hone made in Olean Ny today. Its about the same color as frictionite looks kinda like a dubl duck combination hone. It was filthy and way out of flat so I lapped it... Now its so soft and gritty i can slurry it with my finger! I tried lapping on 600 and even 1500 but it just keeps rapidly shedding material. Did these hones have a fire skin when made? Have I trashed what could have been an awesome hone?!

-

08-03-2012, 04:49 AM #2

James,

Try and post some photos if you can. Maybe someone will spot the reason.

-

08-03-2012, 07:08 AM #3

JamesT,

I had a English barber hone made in the 1920s (cannot remember the brand); it too had become so soft that you could mark it with your finger nail

I don't know if some of these hones were made with early resins as binders, but mine certainly did not look like it had been fired in a kiln.

Whatever it was made from had degraded in the eighty odd years.

Have fun !

Best regards

Russ

-

08-03-2012, 01:22 PM #4Member

- Join Date

- Jul 2012

- Posts

- 39

Thanked: 10

Here are some pictures. See how it just drinks up water, like nothing ive seen from a barbers before

I have been trying to get it right... thought I could break it back in, but it doesnt seem to be working. It's got a bunch of larger grit particles that are doing most of the cutting and as soon as they start to break down, they seem to bust loose and take a little crater of binder with them. I just about to dip this thing in shellac.

-

08-03-2012, 01:27 PM #5

I certainly cannot say whether it is 'ruined' or not. A member who had long experience with old barber hones posted that some of the old ones 'dry out', for lack of a better description. The binder apparently breaks down and the stone essentially will begin to crumble if used. Might be what is happening with yours. It certainly shouldn't slurry at all being a barber hone. IMHO.

-

08-03-2012, 01:29 PM #6At this point in time...

- Join Date

- Jun 2007

- Location

- North Idaho Redoubt

- Posts

- 27,038

- Blog Entries

- 1

Thanked: 13249

You most likely did nothing wrong, sometimes what has been done in the past seems to cause a complete breakdown of the binder...

If that is the problem, I have never figured out how to fix it, so let us know if something works

-

The Following User Says Thank You to gssixgun For This Useful Post:

cudarunner (08-03-2012)

-

08-03-2012, 02:08 PM #7

I did the same with a pike hone the other day.

Before lapping it was ok but after it excatly as your described symptoms "(

I need to fix this

-

08-03-2012, 02:09 PM #8

Btw i tried lapping up to 8000 and it didnt help

-

08-03-2012, 02:21 PM #9Member

- Join Date

- Jul 2012

- Posts

- 39

Thanked: 10

Ive taken it to the lab

... Im going to start messing around with some cut shellac and maybe Minwax wood hardener which is a water thin epoxy. I dont think i can get it factory but i will post what turns out even if it is a disaster. So far its promising! It helped that denatured alcohol was able to clean the gloss out of the embossing, which is what made me think about shellac...

... Im going to start messing around with some cut shellac and maybe Minwax wood hardener which is a water thin epoxy. I dont think i can get it factory but i will post what turns out even if it is a disaster. So far its promising! It helped that denatured alcohol was able to clean the gloss out of the embossing, which is what made me think about shellac...

-

The Following User Says Thank You to JamesT For This Useful Post:

earcutter (08-03-2012)

-

08-03-2012, 02:36 PM #10

20Likes

20Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote