Results 261 to 270 of 478

Thread: South African Hones....

-

11-18-2012, 09:28 PM #261At this point in time...

- Join Date

- Jun 2007

- Location

- North Idaho Redoubt

- Posts

- 26,986

- Blog Entries

- 1

Thanked: 13234

I have used the Smith's Honing Solution which I use on all my oil stones and honestly I saw not enough increase in the edge to lose the feel that I get from just water on that silky slurry,,, I really like the feedback from the Zulu, I haven't done enough Sheffield razors to make a call there yet, but the German, Spanish and American steel I am loving the edges... I haven't run any Swedish or French blades yet either, I would like to try some of the super hard TI's on there to see what it does there..

I really am not a believer in "Double Finishes" ie: going to say a 12k or 16k then going to a natural finisher, I am a firm believer that there is only so much "Edge" available and I think taking it there and then running more finishers on there is not really a good thing, I go straight to every natural finisher from either the Norton 8k or the Naniwa SS 8k, keep in mind I would be totally comfortable with that 8k as a shaving edge with nothing else I have quite a bit of practice there.. So my avdivce is always to achieve a comfortable shaving edge before you hit the Naturals.. The only type of honing I change that rule on is Kamisori becasue I use a Coticule as a pre-finisher and then take it way higher with a Nakayama and slurry but that is a different type of honing. This is why I made the remark above, I doubt there is much of anything left to get sharper from a 16k Shapton, in fact if you used slurry on the Zulu, I would be more inclined to think you actually backed down the sharpness and changed the entire feel of the edge...

I have been reading about 100 plus laps, and honestly I have seen no increse in performance after 40 or so, this could be because of the starting point of the edge when it hits the Zulu I don't know yet...

I don't know yet...

I like the slurry and how it feels and works I haven't done enough work there yet to see a haze finish, I will concentrate on achieving one next but that takes the slurry to break down, and I have to work through if that is even possible, from the feel of the slurry I think it is

As one can see even after a total of about 50 razors so far on this hone I am just now scratching the surface (pun intended) of what might be possible with it..

As I said above I like this hone it is a good feeling solid finisher I love the feel of the slurry I want to mess with that aspect much more and see what I can find buried in that mud..

But I am not comfortable giving honing advice nor comparisons with it yet

Last edited by gssixgun; 11-18-2012 at 09:31 PM.

-

11-18-2012, 09:36 PM #262

-

11-18-2012, 11:09 PM #263Member

- Join Date

- Nov 2012

- Posts

- 96

Thanked: 12 South African Hones....

South African Hones....

Glen. What are you using to make a slurry on this hone?

Down there between your legs, it is like an entertainment complex in the middle of the sewage system. Who designed that?

-Neil deGrasse Tyson

-

11-19-2012, 01:09 AM #264At this point in time...

- Join Date

- Jun 2007

- Location

- North Idaho Redoubt

- Posts

- 26,986

- Blog Entries

- 1

Thanked: 13234

-

11-23-2012, 04:57 AM #265

Hey Guys,

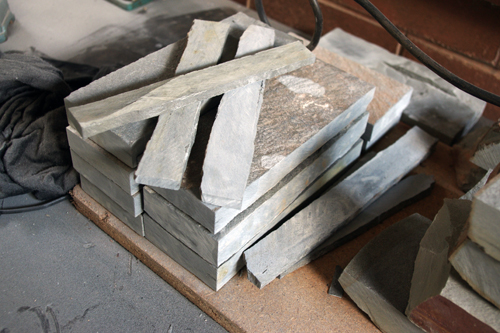

Just a little update.. I sent out 12 more hones last week and am still in the process of finishing another 13 ready to send off in the coming week. If you didn't receive a PM/email then your stone is in this last batch still being prepared. If you did receive your hone in the meantime, it would be really great if you shared your experiences in using the stone here in the thread, as many I'm sure are still keen to hear how it performs with different blades/techniques.

To share a bit of the development of this Zulu Grey adventure with you guys: I've so far invested in a pretty neat masonry cutting machine which allows me to cut the stones to perfect size - so really I can now do any dimension within 2-3mm. The tool works really well and I feel kinda silly having never thought of buying one before. I now have slurry stones for ALL my personal hones from my Norton 8k through to my C12k but of course I also have slightly shorter hones

but of course I also have slightly shorter hones  So that sorts out cutting the blocks to size. However the biggest and most painstaking challenge for me has been making the rough stone flat. Doing it by hand was gruelling to say the least so I've had to think hard about a simple but effective solution.

So that sorts out cutting the blocks to size. However the biggest and most painstaking challenge for me has been making the rough stone flat. Doing it by hand was gruelling to say the least so I've had to think hard about a simple but effective solution.

What I've done is purchase a series of Diamond cup grinding wheels (course, medium, fine) that attach to a standard angle grinder. These are used mostly for shaping/flattening concrete or granite etc. So attaching the cups to my angle grinder and going at the stones freehand worked - but precision is just not on the table.. the cup wheels really remove material quite fast, but you have to really concentrate to get it even slightly true - so basically it's a no-go to do this by hand.

So what I'm doing now is building a very simple swing-arm that screws into the head of the grinder, allowing me to set the height and then swing back and forth over the stones (secured in a milling vise) and so basically it's like a swing-arm surface grinder for stone This will PROPERLY flatten the stones and dramatically speed up processing time.

This will PROPERLY flatten the stones and dramatically speed up processing time.

Now, ADDED to that, I've also gone and got me a range of velcro diamond polishing pads - that also attach to the angle grinder(in my swing-arm setup). These little gems start from 50grit right through to 3000grit. I got 50 through to 1500 though. They work extremely well - Wow. In truth I worked a test piece up to 800grit and it is mirror smooth, truly - so I am stopping at 800grit as it is completely enough... you guys will see what I mean..

So anyway, just wanted to share some of the process with you guys that may be interested. I'll be in touch when the latest batch is shipped. And as always you guys who have been waiting are real gentleman to be sure. Sincerely appreciated.

Cheers,

- Mike

-

The Following 11 Users Say Thank You to MichaelC For This Useful Post:

BobH (11-23-2012), Cangooner (11-23-2012), CatMan (11-24-2012), Havachat45 (11-24-2012), leadingedge (06-02-2013), maddafinga (11-23-2012), Mist (11-23-2012), RogueRazor (11-24-2012), ScottGoodman (11-23-2012), tbert33 (11-23-2012), WW243 (11-23-2012)

-

11-24-2012, 07:27 AM #266

Well, I haven't been at this for very long, so my review must be taken with several grains of salt.

Yesterday, my son and I took a Clauss 5/8 ebay razor, set the bevel on a Chosera 1k, (took forever), and then to a Naniwa SS 3k, and SS 8k, with considerable care. Then, instead of the usual Escher, we used a Zulu Grey on slurry raised with a 325, diluting through about 100 careful x strokes. Then 20 strokes on plain hard felt, and fifty on horse leather. No pastes or sprays.

I shaved with it this morning, and found it to be very comfortable, smooth, and irritation free.

With the caveats above, the Zulu appears to me to be a simple, reliable, and cost-effective path to comfortable shaves.

Don

-

The Following User Says Thank You to Alaska For This Useful Post:

Martin103 (11-24-2012)

-

11-24-2012, 11:24 AM #267

South African Hones....

South African Hones....

Well, I also did some more experiments! Took an e-bay special that I had taken the time to sand and polish, put cheap pre manufactured scales because it looked fine by the edge (had a lot of active rust further up on the blade with some pitting)(first full restore). The blade is a Waterville Cultery Co., american razor made in Waterville Connecticut. Had it for a while like that and on Wednesday decided to give it a go on the Chosera 1K, then 4 & 8K Shapton glass. 30 on hard wool felt and 100 on roo leather.

Shaved, three passes. Overall it was a comfortable shave, after applying the alum there was some tingling on the neck, chin and mustache area for an 85% BBS but a very decent DFS, with no stubbles showing to the naked eye. Decided against touch ups. The ATG was fine every were but you coul feel the edge and more pronaunce on the mustache area, where felt like I couldn't go directly against the grain. Had to used scything motion on most of the mustache and not go directly ATG. Don't know if I could get more out of the 8k, but decided to shave out of the 8k for the foreseeable future before I finish a razor on anything else, just to monitor the progress of my honing and condition of the edge as I take it to a finisher.

On Thursday it was a no shave day, but on Friday, I took it directly to the Zulu (bypassing the 16K). Raised a slury, 30 circles with 10X strokes, then diluted to half the milkiness of the original slury and did another 30 light circles (lighter than the first 30 circles) fallow by 10~15 X strokes. Rinse stone and with water only did 30 circles with 20X strokes, with the last 10X being on an almost dry stone and very light (just weight of the razor). 30 on felt, 100 on roo leather.

Hardly felt the edge on the 3 passes shave for a 95~97% BBS, which I finished with touchups for a total BBS with no alum burn, with the exception of a small patch on the chin area.

The ugly duckling turned out to be an outstanding shaver! Here she Is

Next, I want to take it back to the 8K, shave, see if there is difference from first time, then finish it on the 16k, shave, then try to finish from the 16K on to the Zulu and compare. Double O

-

The Following 3 Users Say Thank You to Double0757 For This Useful Post:

leadingedge (11-24-2012), MichaelC (11-24-2012), RogueRazor (11-24-2012)

-

11-24-2012, 12:05 PM #268I used Nakayamas for my house

- Join Date

- Aug 2009

- Location

- Des Moines

- Posts

- 8,664

- Blog Entries

- 1

Thanked: 2591

-

11-27-2012, 02:36 PM #269

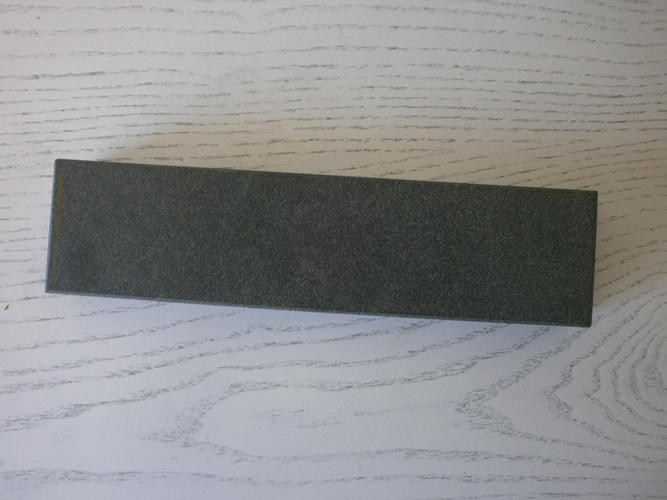

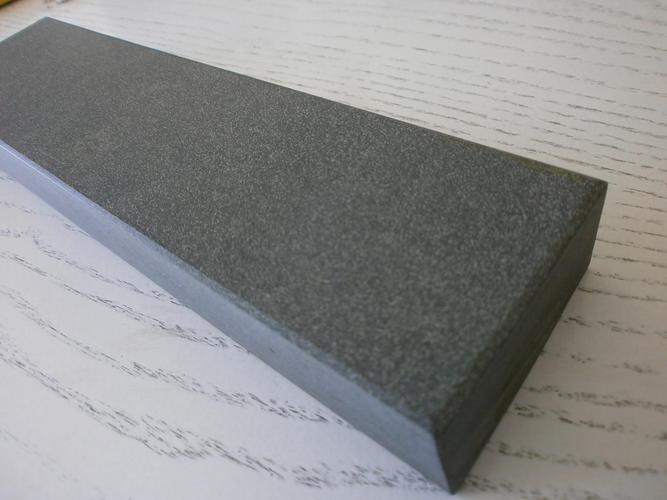

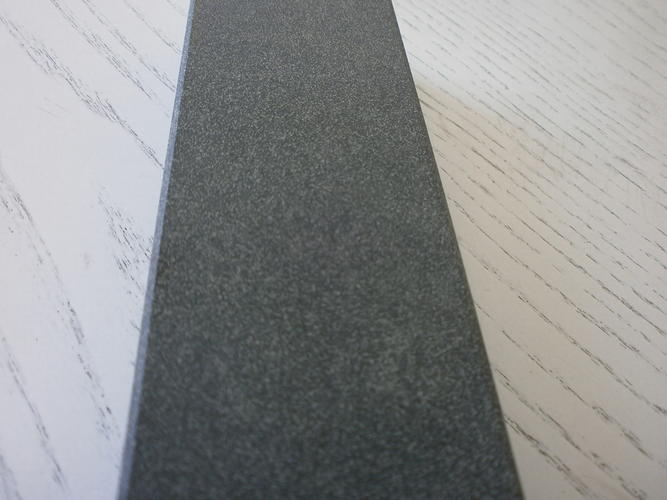

I received my stone today. 8x2", my favourite size. It looks great. On the last photo I have the razors I will hone. the one is W.H. Humphreys and the other John Clarke? Clamme? (can't read it but I have its name somewhere and it my best razor, I take it with me whenever I go) and son, both old trusty sheffield razors.

I will try them tonight and post my results.

-

11-27-2012, 05:13 PM #270

Hi Guys,

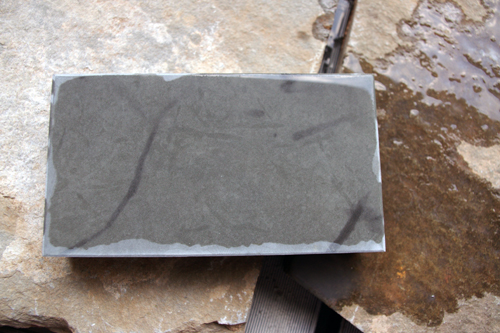

I just wanted to post some progress images. You can see a bit of my stone-surface-grinder-contraption in one of the shots. The stone you see here just has such a nice figuring that really wasn't visible until I lapped it up to 800 grit with these diamond pads. It's amazing really, how this seemingly light-coloured stone, deepens in colour and the figuring pops out as you go up in grits...

As I understand it, the dark marks are from organic matter like seaweed, embedded between layers and compressed over all that time. Rather Beautiful no?

- Mike.

-

The Following 2 Users Say Thank You to MichaelC For This Useful Post:

Havachat45 (11-28-2012), ScottGoodman (11-27-2012)

479Likes

479Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote I think I can help you out with that, Glen. I will be contacting you soon.

I think I can help you out with that, Glen. I will be contacting you soon.