Results 361 to 370 of 478

Thread: South African Hones....

-

01-11-2013, 05:43 PM #361

South African Hones....

South African Hones....

Hi Brook, thanks for the feed back! I was thinking I could simulate (synthetically) what's happening with friable grit stones, that as you work the slurry, it breaks down in smaller garnets or what ever, polishing further the edge, than when you start with the original slury.

I've taken two blades on a progression of 8k, 16k, Zulu gray water only, .25CBN diluted slury (like just slightly cloudy water) 25-30 X strokes, clean stone and use .01CBN diluted slury( same as the .25cbn) and do another 25-30 strokes. On the second blade I think I did more strokes. I test the progression of the edge with TPT, both side ways and along the edge to see how much it digs in an resist the thumb sliding on the edge. I also use the hairs on my thighs, or any part of my leg that still have hair(I bike, so it's a speed thing, LOL) to see the sharpness along the edge. that's how I know if an edge improve or digress after every stage, until the final test, the shave.

Things I've found, using heavy slury sets the edge back on sharpness. When I did the first blade, that's what happen, the slury was milky (with the .25cbn) and the edge degraded. After diluting, edge came right back. And that is why I would like to try the natural friable stones, like asano botan, tenjou, mejiro and tomo nagura. I don't know anything about Jnats, and I'm quoting stones from what you wrote on another thread (friable stones), because if it works, you could use the ZG as a Jnat.

I'll use this year 2013 to read on Jnats and to further get to know the Zulu Grey and the Turingians. By end of year, I'll be ready to buy a Jnat and it's respective slury stones. Then I'll try them on the Zulu and see. Who knows, maybe I'll sell all the stones and keep the Zulu with the Jnats friable stones, or sell all the other stones and keep the Jnat, or more likely, don't sell anything and keep them all. "Because edges on finishers are like a box of chocolate, you never know what you're going to get". Double O

-

01-11-2013, 06:00 PM #362I used Nakayamas for my house

- Join Date

- Aug 2009

- Location

- Des Moines

- Posts

- 8,664

- Blog Entries

- 1

Thanked: 2591

how do you know that the Zulu gray grit is not friable?

IMO people make the big mistake to count strokes when honing on slurry on naturals. The slurry will break down at its own pace depending on the base stone, the slurry type, the razor used. In this sense counting does not mean anything as the number of laps will vary. For me best way to tell when to stop is by feel, with enough practice one learns how to tell when the razor is ready.Stefan

-

01-11-2013, 06:51 PM #363

South African Hones....

South African Hones....

I don't know if it is or not. All I know is that the edges improve as I dilute the Zulu slury to water only, and from the little I have read on Jnats, people leave the slury on till they finished. Maybe it's kind of a friable slury that doesn't make it practical to leave the slury on all the way (slow friable?).

I like to experiment and see if I can take it to the next level (OCD?) I've been honing daily for the past few months. Shaving with two, sometimes three blades at a time. Testing blades out of the 8K, or just out of the Zulu after the 8k and the other out of the Zulu after the 16k. It's been crazy. Now I have added other stones, Turingians and a Turingian Hohenzollern to the mix. Yes, it's my own OCD. Lately I have been enjoying one blade at a time, because I feel I have a better control on the honing process from bevel to finish. I'm still stopping on the 8k and shaving, to make sure it has a fighting chance when I get them to the finishers.

Yes, I agree, I stopped counting strokes as a method of sharpening a little while ago. I now go by feel of the blade on the stone, TPT and hair test. It is a slow prosses for me, as I lack experience, but I'm finding that I have a better understanding what the stone and my strokes are doing to the edge, and thence having more control on how to proceed with what I have. I still count strokes (or guesstimate sometimes) for future reference. Like when I take a Sheffield wedge I know now I don't need to start feeling until at least 150 strokes, vs a solingen hollow ground, strat paying attention after maybe 40-60 strokes on the Zulu. Like when you first learn stick shift, you change gears by the rpm, later by sound and feel and much later for what ever you wanted out of the car (honemeister). Double O

-

01-22-2013, 05:53 AM #364

South African Hones....

South African Hones....

Just shaved with my latest experiment and it was a success!

I have been reading and watching videos of some Jnats honing. I have several 1" wide vintage Turingians that I have found to be slow and finicky due to the size. So I got thinking, Zulu "hard stone that don't slury by itself", Turingian, "esay to slury and possible more friable than the Zulu". So, with small Turingian in hand and Zulu on the hone holder, I raised some milky slury on the Zulu by just rubbing the Turingian over the Zulu. Using very light circles and x stokes, little water and not diluting the slury (a la Janat), I got very sharp and smooth Torry to shave in 3 passes, little touchups for 100% BBS with no alum burn.

I've done a Torry on the Zulu alone, then on the Honhensollern (yellow green Turingian) and the edge of the later, I found smoother than with the Zulu (not that the one with the Zulu wasn't smooth). Feeling this new Torry edge that I just shaved with, I would describe closer to the Turingian smooth than the Zulu alone. I like the smoothness of the Turingian and the size and easiness of the Zulu. I would do others with this same procedure to see if it was luck or science. Double O

-

The Following User Says Thank You to Double0757 For This Useful Post:

lz6 (01-22-2013)

-

01-22-2013, 10:45 AM #365

Hi Guys,

I fear this thread is becoming a bit unwieldy, but thanks indeed for all the dedicated contributions to it.

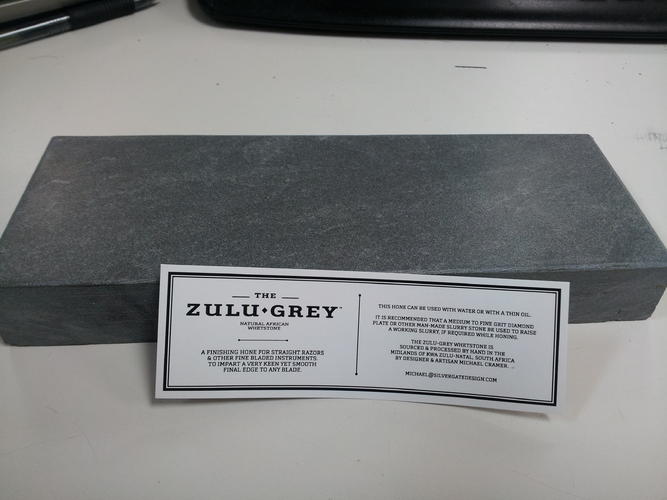

I wanted to post something a bit off topic and was hoping you guys could give me your thoughts on this.

During the cutting of these hones, I often have to trim/split bigger pieces to create as neat a hone shape as I can, but in the process there are a lot of what I call thin-cuts that are accumulating. In particular there are trimmed pieces that are about 1 inch wide x 8 inches long and they are of differing thicknesses. Now I for one feel that a 1 inch hone is very handy especially for smiling blades as they offer more control in the rolling-X action. I personally even prefer narrower hones in general as they seem to allow me more control in contacting the edge all the way along..

My question is do others also prefer narrow finishing stones? I know Neil Miller appreciates the narrow hones, but was interested to see what the general consensus was among you guys.

These thin-cuts are growing in numbers, and my thinking is that they can quite easily be lapped and mounted to small wooden paddles and put to work!

- Mike.

-

01-22-2013, 11:49 AM #366

Seems like a good idea to me. Although, I hasten to add, I am very happy with my "full size" 3x8 Zulu Grey so I don't think I would rush to buy one.

-

The Following User Says Thank You to Storsven For This Useful Post:

MichaelC (01-22-2013)

-

01-22-2013, 01:08 PM #367

Hey, I like 'unwieldy.!' It makes you hone your wieldy skills. My favorite active thread. If it gets too wieldy, it might sound like: what is your favorite side of the razor to shave with after you have used MWF ATG?

Last edited by WW243; 01-22-2013 at 01:16 PM.

"Call me Ishmael"

CUTS LANE WOOL HAIR LIKE A Saus-AGE!

-

01-22-2013, 02:26 PM #368

I'm glad I got my 3x8 Zulu, but I will say that I do enjoy honing with my little 5x1" Thuringian as well. It is an absolute joy to use, and circles/rolling x's are very easy to do on it once you get the hang of it. Here's a pic just for the heck of it:

So yes, I do think that there is a place for "thinner" stones, Michael. In fact, I like my little thuri so much that I would be tempted to add a "little brother" to my bigger Zulu at some point if they become available...

Regards,

JPLast edited by jpcwon; 01-22-2013 at 02:31 PM.

-JP-

-

01-22-2013, 07:24 PM #369

Well, after 2 months of patient waiting, I am happy to announce that the newest member of the "jpcwon HAD Team" has arrived!! It's an 8x3" Zulu Grey, and is even pretter in person! Unfortunately I am at work right now & cannot use it, but I just wanted to post pics & I will be sure to post a review of the stone as soon as I get a chance to use it. I want to thank MichaelC for making these wonderful stones available!

-JP-

-JP-

-

The Following User Says Thank You to jpcwon For This Useful Post:

MichaelC (01-24-2013)

-

01-23-2013, 01:16 AM #370

-

The Following User Says Thank You to leadingedge For This Useful Post:

MichaelC (01-24-2013)

479Likes

479Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote