Results 21 to 30 of 49

-

12-10-2013, 03:50 PM #21Senior Member

- Join Date

- Apr 2008

- Location

- Essex, UK

- Posts

- 3,816

Thanked: 3164

-

12-10-2013, 04:01 PM #22

Simple answer,,,it's a guy who likes leeches,,

A leech guy is an individual who is certified to house, maintain & sell leeches. He is also an authority on leeches. A woman can be a leech guy also, in this case she would be referred to as a leech gal.

Just keep in mind that a leech guy does not make a lot of money, so never leech off of a leech guy.

-

The Following User Says Thank You to Hirlau For This Useful Post:

Neil Miller (12-10-2013)

-

12-10-2013, 04:18 PM #23

Your barber hone(s) must be of a vastly different breed than mine.

Either that, or defective.

The ones I have will restore a dulling edge in 5-10 laps most of the time, and never more than 15.

I have done razors on them, including bevel set using both sides, and the entire process was not even close to 1500 laps.

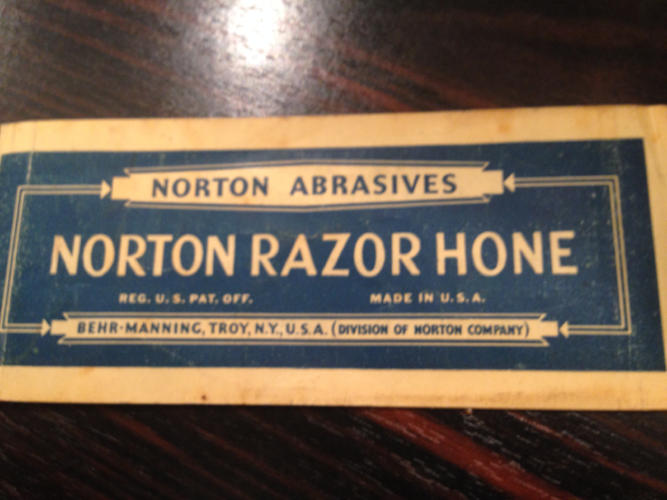

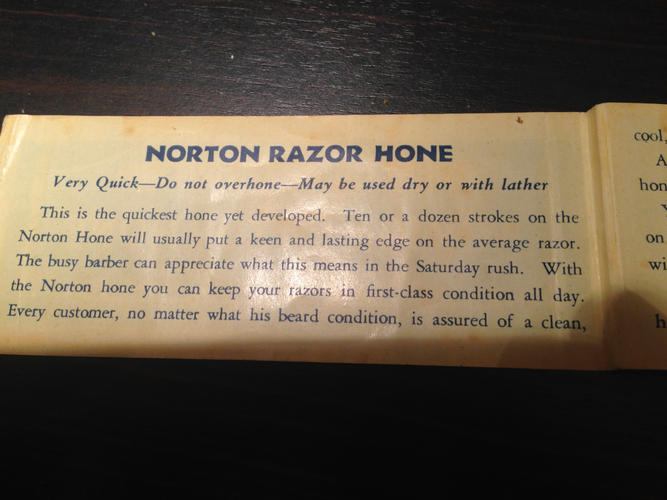

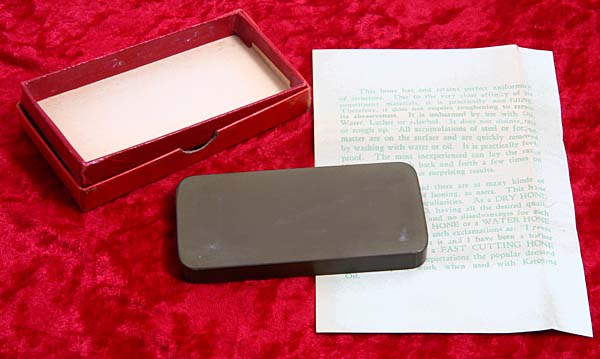

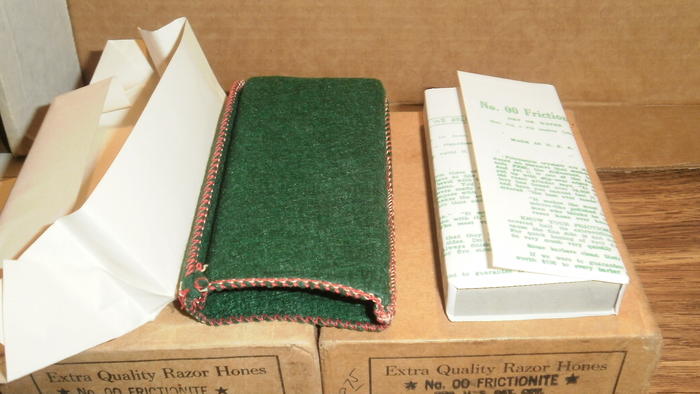

Here is a picture of the user instructions on one of mine, indicating something similar to what I wrote above.

I'm not sure what is going on with your results there at all, but I thought I would post my findings on my barber hones to avoid people trying to copy those 1500 laps and basically grind away their razors

If their barber hones are anything like mine that is!Bjoernar

Um, all of them, any of them that have been in front of me over all these years....

-

The Following 5 Users Say Thank You to Birnando For This Useful Post:

crouton976 (12-12-2013), Hirlau (12-10-2013), jmercer (12-08-2015), souschefdude (12-12-2013), Wolfpack34 (12-10-2013)

-

12-10-2013, 05:08 PM #24Senior Member

- Join Date

- Apr 2008

- Location

- Essex, UK

- Posts

- 3,816

Thanked: 3164

I must say Bjoernar's post echoes my experience:

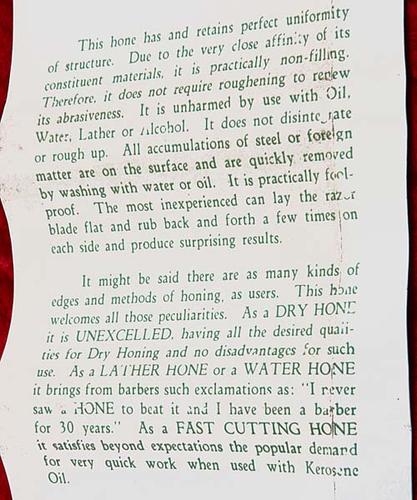

The above is a no-name barbers hone which surprisingly advocates rubbing the blade up and down on one side for a few strokes then flipping and repeating on the other side.

The Raven, above, only took 5 to 7 laps.

The Primo, above, says to use just "a few" strokes.

With regard to excessive wer being caused by barbers hones, that is probably due to too many laps or over use of the coarse side of a combo hone:

The CMon is shown coarse side up - the other side is brown and is the finisher.

Regards,

Neil

-

The Following 3 Users Say Thank You to Neil Miller For This Useful Post:

crouton976 (12-12-2013), jmercer (12-08-2015), Wolfpack34 (12-10-2013)

-

12-10-2013, 05:17 PM #25

If I understand, I'm reading here you would place the blade on the hone and rub it back and forth 7-10 times then flip the blade over and do the same?

I have a Boker Barber's hone, supposed to be a dry hone, and am wondering do I place the blade flat and do an L strop 7-10 times in only one direction, then flip it over and do the same?

Thanks!

-

12-10-2013, 05:41 PM #26Senior Member

- Join Date

- Apr 2008

- Location

- Essex, UK

- Posts

- 3,816

Thanked: 3164

I'm not sure, Phrank.

The instructions with the no-name hone say to "lay the blade flat and rub back and forth a few times" then flip it over and repeat. Rubbing up and down a few times probably equates 4 up-down movements, so say if you used it conventionally that would be 4 laps.

I never used one like that, although thats exactly what I do in some stages of conventional honing - I believe they call it 'half-laps' for some strange reason!

Regards,

Neil

-

The Following User Says Thank You to Neil Miller For This Useful Post:

Phrank (12-10-2013)

-

12-10-2013, 06:00 PM #27

-

12-10-2013, 06:39 PM #28Senior Member

- Join Date

- Jul 2013

- Posts

- 444

Thanked: 18

It's a great questoin. Especially since the barber's livelihood is about processing customers. Time sharpening was surely going to be seen as a necessary waste, not the 'hobby' we see today.

There are a LOT of dished stones on the market that are fairly old. That gives us some indication of practical requirements vs modern fastidiousness.

-

12-10-2013, 06:41 PM #29

Birnando is correct IMO...

Barber hones were designed for Barber's (or individuals) to periodically refresh a blade. This kept the razor serviceable for a much longer time between actual honing sessions...especially for Barbers that might shave many several different faces and beards daily. Most instructions that came with them indicated as much. As few as 4-5 strokes on some...as much as 15 strokes on others.

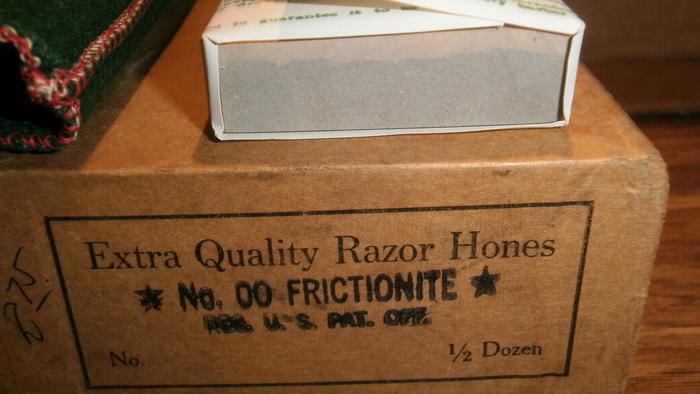

They (some) do make very nice finishers as the final stone to use after an 8k or even a 12k. Using water of lather usually increases the fineness (or 'feel') of the particular Barber's Hone being used. The ones that say to use 'DRY' are usually more aggressive cutters. Swattys, Aparts, Nortons (Pike's), Frictionites, and many many others were as fine as 12-15K.

That is not to say that you cannot use them as a regular hone. I have used 'only' a Barber hone to completely repair and finish more than a few EBAY junkers and have gotten many a BBS shave this way. One thing to keep in mind however when purchasing one of these older hones is the condition of the hone. Over time many of them have degraded to the point that they have become very unreliable. They were after all 'manufactured' from ingredient compositions. Some, not all, would degrade or 'break down' due to over exposure to heat, sunlight, acidic soaps, etc. and also just the passage of time. The vaunted Frictionite '00' ...in MHO in the TOP TWO of Barber Hones...came with a warning that stated as much.

One thing to be careful of when purchasing these old Barber Hones is the presence of 'holes' or 'pits' on the hone face, which would be indicative of a breakdown of the hone's composition. Also...excessive 'crazing' will indicate a degraded condition.

Just MHO...YMMV...

WP34

Last edited by Wolfpack34; 12-10-2013 at 06:46 PM.

Lupus Cohors - Appellant Mors !

-

The Following User Says Thank You to Wolfpack34 For This Useful Post:

Neil Miller (12-10-2013)

-

12-10-2013, 07:07 PM #30Senior Member

- Join Date

- Apr 2008

- Location

- Essex, UK

- Posts

- 3,816

Thanked: 3164

I think the way they breakdown and to some degree the fineness, depends on how they were made. There seem to be 'hot' barber hones that were baked and 'cold' barber hones that were left to set. The binder used plays a part, too. The later production hones used either an 'earth' binder or a 'resin' binder. Earlier ones used shellac as a binder, some even used potassium dichromate and gum - pot. di. hardens gum when exposed to ultra violet life.

I would suspect that the gum-types (which must be quite rare now) and shellac ones would eventually soften up, and that earth binders that were baked would last better than resin binders that were left to set-up. Some that give reasonable results as-is often fail dramatically after an attempt has been made to lap them, perhaps because the finer layer of surface aggregates has been lapped away - you find this in cast concrete - the 'laitance' collects at the sides and top and looks very fine and shiny - chip it and the particles look much coarser.

Just an idea - I don't know exactly one way or the other, except that they are man-made and all man-made things seem to succumb to the ravages of time sooner or later.

Regards,

Neil

PS: you lucky so-and-so, Wolfpack - a carton of half a dozen pristine hones - who did you hold up?

-

The Following User Says Thank You to Neil Miller For This Useful Post:

Wolfpack34 (12-10-2013)

61Likes

61Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote