Results 1 to 10 of 17

Thread: Phenomenon on Jnats?

-

09-09-2014, 04:43 AM #1

Phenomenon on Jnats?

Phenomenon on Jnats?

I just put my new Ohira through a half session (mid-grit nagura to mostly water several times, with a lot of slurry from the hone toward the end).

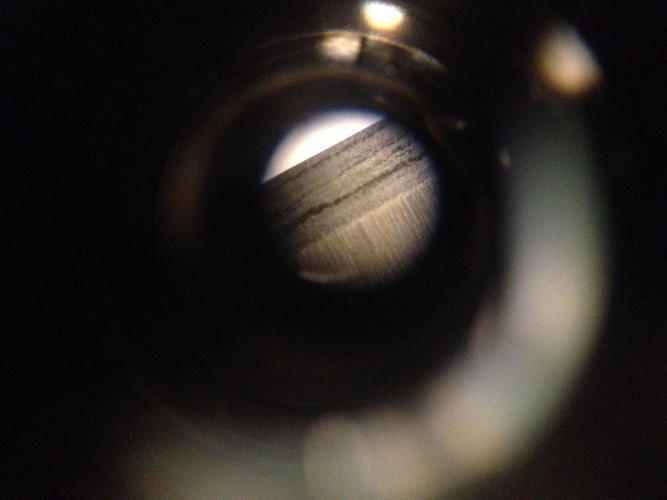

A strange thing happened... I got past the striations and ended up with a hazy polished edge (sparkly steel under the 40x hand microscope), but wavy lines emerged on the bevel... Like Damascus but this razor is O1.

Not sure if you can make it out in the pics.

Does anyone else experience this?

By the way, do Jnats generally need to be broken in? I didn't lap mine, as I only have a 220 DMT, but it strikes me that it's either getting smoother or I am getting used to the lighter passes on finishing (which I have found are easier when holding the hone in my hand-- I may be applying too much pressure when on the table).

-

09-09-2014, 01:56 PM #2

Here is the striping under crappy magnification.

-

09-09-2014, 02:32 PM #3

Can't say that ve ever seen striping like that - are you sure the bevel is clean of slurry, like a palm or leather strop stroke or two?

JNats don't need breaking in, but 220 grit is a very coarse finish that will affect the razor finish, at least initially. I usually take mine up to at least 1200 grit with a worn Atoma plate or 1200 w/d sandpaper on plate glass then burnish with a nagura, botan or a tomo.

Cheers, Steve

-

09-09-2014, 02:39 PM #4

I've no idea what could be causing that but don't think it can be the hone - purely on the basis that those lines are running parallel with the edge and you hone at an angle to the edge.

Yes it's advisable to lap any stone - natural or synthetic. You can use wet and dry paper on a flat base and work up the grits.My service is good, fast and cheap. Select any two and discount the third.

-

09-09-2014, 02:45 PM #5

Yep, I have cleaned the edge... it had me confused at the start as well.

I may go back and sand tonight. I have some w/d left in grits up to 1000 or 2000.

Fascinating stone, although somehow different than I expected.

I think I may take that blade back to my King 1200 and back up to see if the stripes happen again.

-

09-09-2014, 05:51 PM #6Senior Member

- Join Date

- Jul 2011

- Posts

- 2,110

Thanked: 459

What did it shave like? It's unusual to see layers in O1 steel unless it was hammered with something.

-

09-09-2014, 06:08 PM #7

Was the blade forged or stock removed when made? could be laminations not good. Otherwise could be alloy banding or trustite both a heat treatment artefact which wont hurt. In my experience it's best to lap your jnat and finish lap with a coticule or similar grit hone, preferably a coticule.

-

09-09-2014, 06:28 PM #8

Thanks, guys. This one was stock removal, but I did a version of ghetto heat treat with a fire brick forge and pencil torch into warmed cooking oil.

I haven't shaved with it properly but will try after I lap and bevel set again.

Thanks for the note re using the coticule to lap. I like the sound of that, and will wash both hones thoroughly after.

-

09-09-2014, 08:25 PM #9

Here's a thought: did you strop your edge before that pic was taken, & have you recently treated your strop w/ anything? That could be residue coming off the strop. I had something similar one a razor once shortly after treating an old strop w/ lexol. It was just strop residue.

As far as lapping your hone goes, no, a coarse stone surface will not cause patterns like that on steel. Depending on how worn your DMT is, the 220 may indeed be a little coarse, but if using slurry, most of the scratches will get filled in anyway. If you have a 325, you could use that to smooth the surface. I personally am not a fan of lapping hard naturals w/ other hard naturals. The risk of scratching is too great to be worth it IME & it takes forever. Plus, if your stone is thinner & the 2 stones get stuck together, you could break it trying to separate them.

-

09-09-2014, 09:06 PM #10

Nope. Clean bridle leather. I'll also see if the coti produces a similar look.

2Likes

2Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote