Results 1 to 10 of 21

Threaded View

-

05-22-2015, 03:33 PM #1

Remote assistance required - to hone a razor

Remote assistance required - to hone a razor

Hi,

I have been a member for some time and shaving every day with a straight for the past few years - something I look forward to every morning.

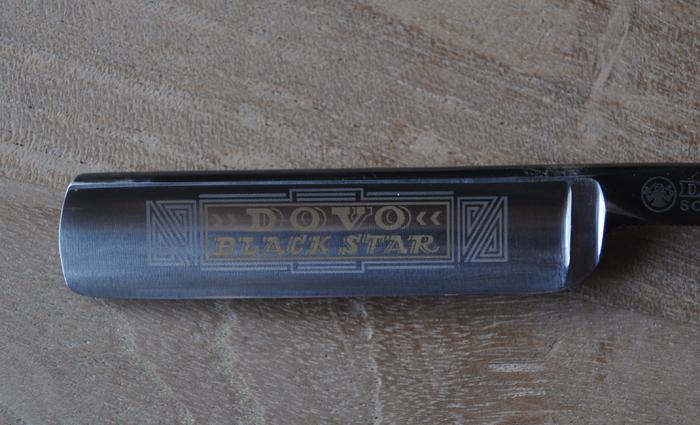

Right when I started my brother in Belgium sent me a Dovo Black Star razor - my first. Since then I acquired quite a few more and I am fortunate to shave with a different razor every day of the week.

I have never successfully honed a razor and only tried with one the Dovo (before I was a member at SRP) which I royally messed up - I am sure it will be easy to spot in the pics. Recently I got a Norton 1000 and 4000/8000 and I would like to try my hand at getting the Dovo into shape. As I live in Africa I cannot drive across to someone to assist me in fixing this Dovo.

Since I have a good camera I thought I would take some pics and request that members on the forum provide me some advice in terms of what they think I should do to set a bevel and then to get it to shave ready. I would be able to document the process as it progresses.

Looking forward to assistance from members in the forum.

16Likes

16Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote