Results 11 to 19 of 19

-

10-05-2015, 03:46 PM #11Junior Member

- Join Date

- Oct 2015

- Posts

- 6

Thanked: 0

I have the green and blue dmt diamond stones, Norton 4k/8k. I flatten that on a sanding screens on tempered glass. I use scribbled lead lines edged-to-edge for reference. I have green hone stick, and will have a leather strop and diamond paste (down to .25 micron) this week. I've tried green hone on mdf but might try a softer substrate like balsa if you guys think that'd help. Ideally I want to keep it as simple as possible when it comes to honing. I'll send more pics. I like the 45 degree idea, provided I'm slow enough to prevent chatter, in that it seems like a quick way to straighten a wavy edge. Creating a new bevel doesn't too hard. I'll read over the material suggested and the responses here before preceding. Thank you very much everyone!

-

10-05-2015, 03:48 PM #12

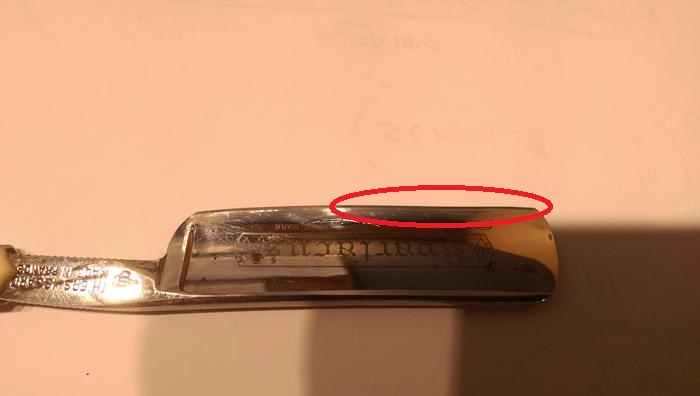

If you are the only one who has honed the razor, it appears you may have honed into the shoulder. If it was in someone's else's hands, they seem to have honed into the shoulder.

"Call me Ishmael"

CUTS LANE WOOL HAIR LIKE A Saus-AGE!

-

10-05-2015, 04:29 PM #13Junior Member

- Join Date

- Oct 2015

- Posts

- 6

Thanked: 0

That was all me. Probably did it when I was a teenager and had even less knowledge than today...which is scarey. Hopefully that's just a cosmetic issue.

-

10-05-2015, 04:42 PM #14I used Nakayamas for my house

- Join Date

- Aug 2009

- Location

- Des Moines

- Posts

- 8,664

- Blog Entries

- 1

Thanked: 2591

-

10-05-2015, 04:46 PM #15

I'd encourage you to fall back and regroup. You have a nice razor. Slow and steady wins the race. There are many threads for all levels of honing skills here, from the basic, to the level of Quantum physics, and into Mysticism. Good Luck!

"Call me Ishmael"

CUTS LANE WOOL HAIR LIKE A Saus-AGE!

-

10-05-2015, 04:48 PM #16

The bottom half of the shoulder and the scratching near the bevel at the heel. It could be the light...

"Call me Ishmael"

CUTS LANE WOOL HAIR LIKE A Saus-AGE!

-

10-05-2015, 09:02 PM #17Senior Member

- Join Date

- Jul 2011

- Posts

- 2,110

Thanked: 459

I would (perhaps this is sort of already said in total) joint the front of that razor at the tip so that it's a continuous smile. Then spot set the bevel on the jointed area until the bevel is uniform, and run through your progression.

I no qualms about jointing a spot just like you'd do with a chisel or iron to get the geometry back to proper, but it's something you'd need to do only one time ever to the razor and it's a minimal amount (at 90 degrees, the dip at the nose will disappear on a medium stone in a few strokes. It'll take more to rework the bevel at the front, but there's no reason to breadknife/joint the whole edge, only the part that needs to be removed.

Some of this stuff about changing the geometry of an edge reminds me of woodworking with hand tools. A lot of newbies to woodworking with hand tools only will want a method that they can use on every board, but eventually, being sparing and preserving what you have will lead you to work areas that need to be removed only. On a piece of rough lumber, that would mean planing the high spots off before going at it on the whole board. It's less effort and there's more wood left when you're done. Same as there will be more razor left here.

Of course, if you have a good non-abrasive linen, there's probably 200 years of shaves left in that razor, anyway. It'll be dropped or banged into something long before it actually wears out.

If you hone it heavily every couple of weeks, its prognosis isn't so good!!

-

10-13-2015, 02:11 PM #18Junior Member

- Join Date

- Oct 2015

- Posts

- 6

Thanked: 0

All is well. I straightened the edge of the blade with 45 degree movements on a 45 micron diamond stone. Used a 120 power hand held microscope to check out the bevel as I progressively honed to 1 micron (i have yet to use my diamond pastes). Shaves like a dream now. After I found my mojo, I found that honing was pretty fast. Stropped and have been shaving with it for a few days. Very satisfied with the results. The next challenge is convincing my wife I'm not completely insane.

-

10-29-2015, 10:52 PM #19Senior Member

- Join Date

- Sep 2015

- Posts

- 695

Thanked: 77

When my razor did that I changed my honing style and it stopped

10Likes

10Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote