Results 31 to 40 of 85

-

11-24-2015, 05:01 PM #31

Great thread as I am in the process of doing my first hone

Learning lots thanx

-

11-24-2015, 07:08 PM #32

So, I used the 1K, blade at 45 degree angle to do some preliminary work on the bevel.

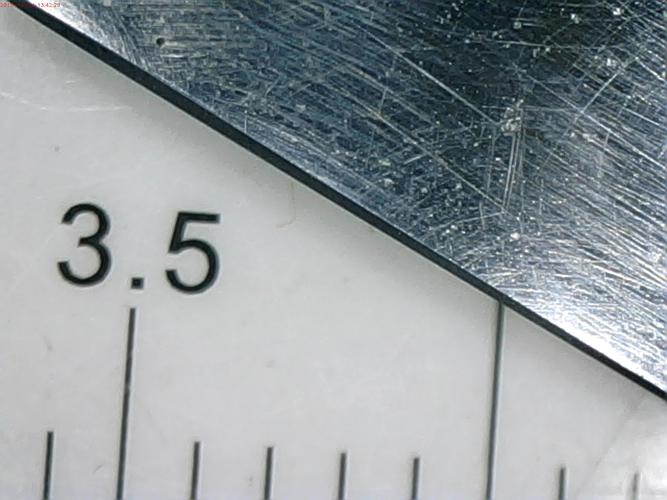

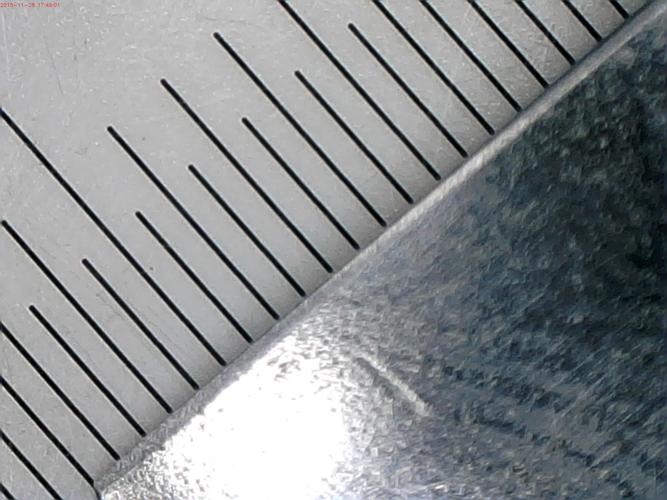

The width looks pretty even, except two places. About 1/3 of the way, from the toe, it is a little wider:

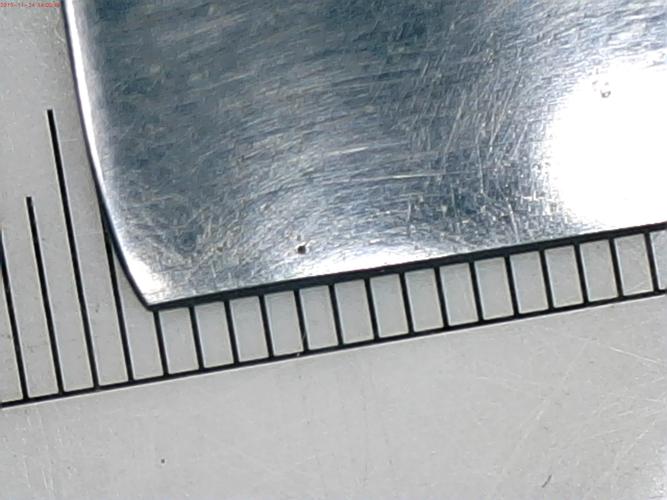

Near the toe on one side, it is pretty even, but on the other side, it is almost non-existent (some of these are a bit blurry):

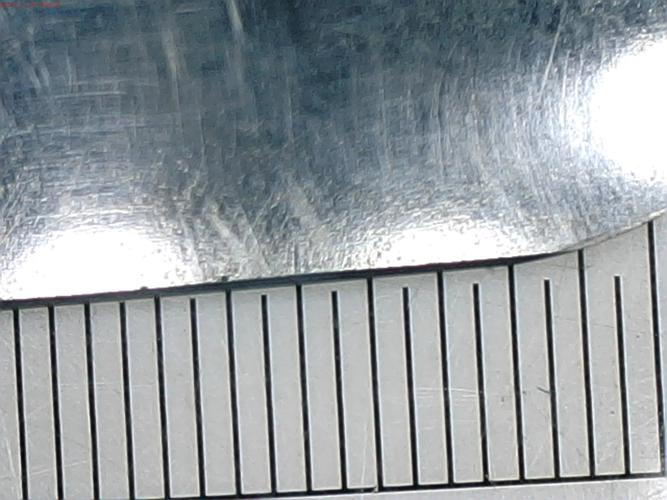

The heel seems pretty good:

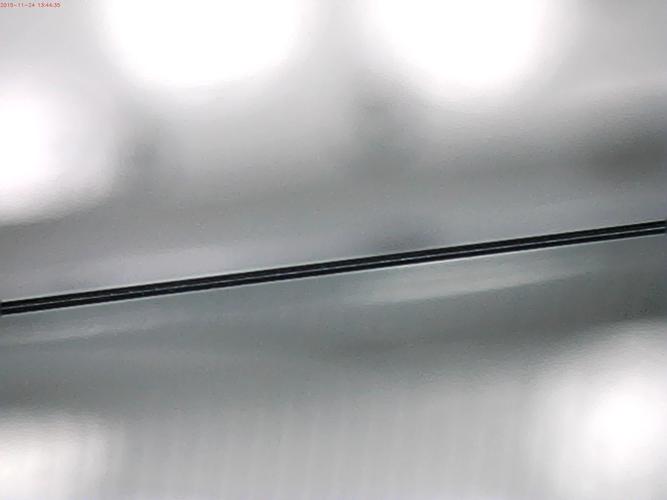

Here the edge, at lower rez. It is even in some areas, and then seems to vary a tiny bit in others, and seems off near the toe:

A few questions...

1) Should I hone longer at a 45 degree angle, or drop down to two tape layers?

2) Should I address the end of the toe not having a bevel yet on one side, and if so how?

3) Should I address the fact that the bevel is really close to meeting over most of the blade, but there are areas where there is a wider gap, and if so how?

4) Should I address the fact that the bevel is not centered near the toe, and if so how?

5) Looking for light under the edge, I do still see a bit at the toe, and a tiny bit at the heel. Do I need to flatten more?

Thanks in advance!Last edited by pcm; 11-24-2015 at 07:17 PM.

Regards,

PCM

-

11-24-2015, 07:16 PM #33

I thought, coming into this, I was just going to hone a bevel on this blade and be done. Especially since, it was cutting arm hair somewhat, when I got it.

Through the great input here, I've found that this blade needed quite a bit (to me) of repair, beyond honing out chips that I first saw. The heel needed to be shaped some, there was an uneven edge, the bevel width varied considerably, and it needed some real cleaning.

I'm learning a whole lot. Glad to see other people are picking up some things too!Regards,

PCM

-

The Following User Says Thank You to pcm For This Useful Post:

DZEC (03-30-2019)

-

11-28-2015, 11:00 PM #34

I decided to try to flatten the edge more, so I used the DMT and did more strokes, so that I really couldn't see light, almost end to end. Then, on the 1K Norton, at a 45 degree angle (spine off stone), I tried to set a "rough" bevel, getting it close to meeting. I do see that on one side, the bevel is about the same width, although a bit narrower as it goes toward the heel. On the other side it varies a bit (smaller) about 1/3 of the way from the toe.

I tried doing some strokes, with a finger applying some press at that point, while doing the 45 degree angle strokes.

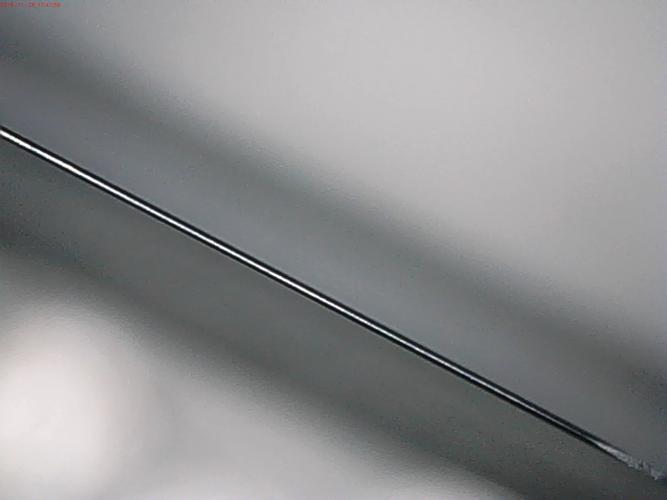

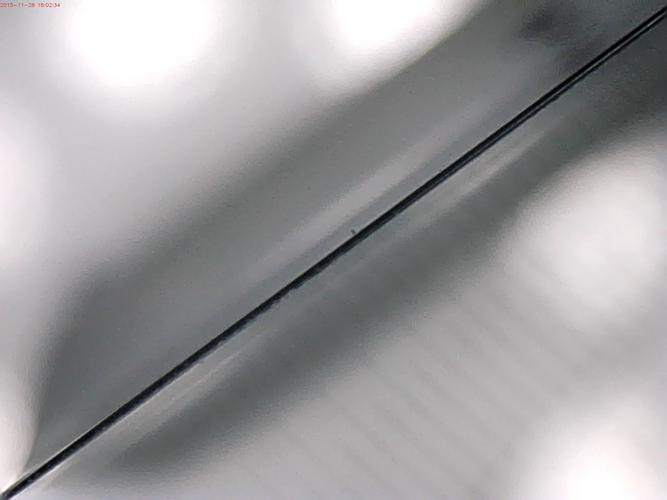

Here is what I have now, showing the edge, head on, and then the bevel on each side. The closeness (or lack of) of the two bevel meeting seems to vary some, along the length. The width of the bevel seems more consistent now, however.

Should I try to adjust the bevel width more (and if so how)?

Should I try to bring the bevels closer to meeting, using more strokes with the 45 degree angle, or switch to two layers of tape and hone with a leading heel?

Is pressing on the edge with a finger, the way to try to compensate? Will I need to do that through the whole 1K process?

Thanks in advance!Regards,

PCM

-

11-28-2015, 11:10 PM #35

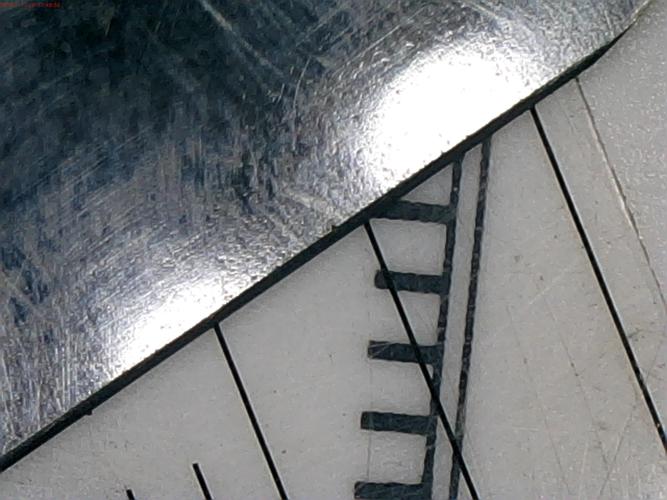

Here's another shot of the toe, as the last one was a bit fuzzy:

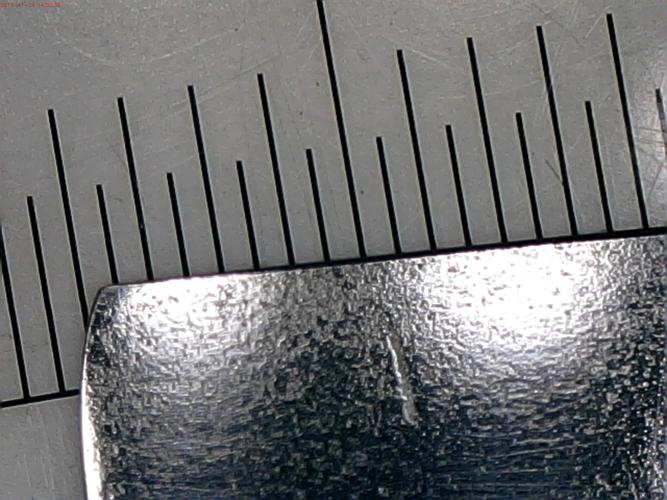

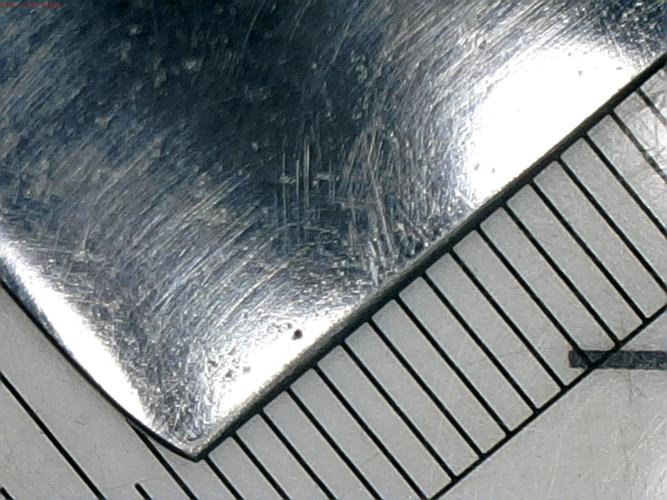

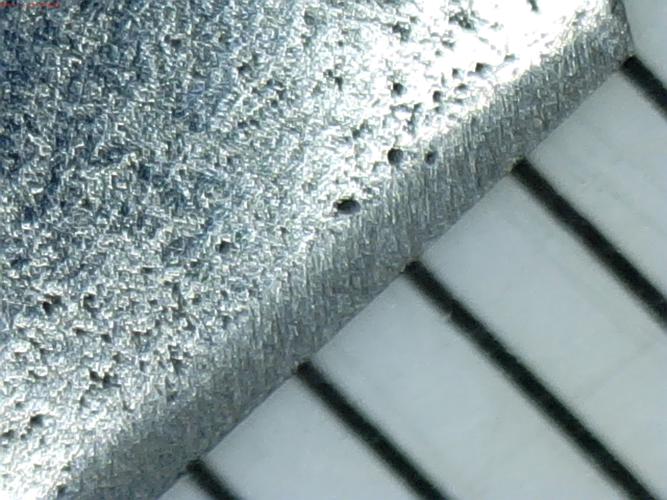

There is some old bevel there, and still doesn't seem to meet. Here is a close up of the toe on each side (hash marks are 1mm):

On the first one, I think the new bevel is far away from the edge still. Is that because the last 1/8" is still not flat compared to the rest?

Should I continue trying to flatten more, or use some other technique to try to set the bevel at the toe?Regards,

PCM

-

11-30-2015, 06:55 AM #36Senior Member

- Join Date

- Apr 2012

- Location

- Diamond Bar, CA

- Posts

- 6,553

Thanked: 3215

So, the 45 degree spine off the hone honing, is just to knock off the corner and save you some time on the 1k. The bevel will not be even or maybe not complete, you are free-hand honing and there is no guide.

Now, put it spine on the stone with tape on the bevel and hone the bevel until they are flat and complete. Some ink on the bevel will help you see your progress easier.

When you think the bevels are meeting look straight down on the edge with magnification, any shiny reflections are where they are not meeting and the bevel is not fully set.

-

12-01-2015, 06:18 AM #37Senior Member

- Join Date

- Apr 2012

- Location

- Diamond Bar, CA

- Posts

- 6,553

Thanked: 3215

So, a couple points of clarification.

Do not worry about the width or shape of the bevel, the goal is the edge. While there are gyrations you can do to adjust the bevel width or shape, it does not affect the edge and shave if the bevels are not symmetrical, especially with a vintage, abused razor.

A lot of this kind of thinking comes from knife websites, especially now with the proliferation of honing jigs and their way over the top obsession with the appearance of knife bevels.

As an aside, I have a few, one of which is the Edge Pro and it certainly capable of putting a very nice even bevel and edge on a knife, great for smaller EDC. I get the obsession, but honing a knife with a jig and a vintage razor are two different kettles of fish. I doubt many working chefs are sharpening daily on a jig, I don’t care how perfect the bevels are.

So to the OP don’t worry about how the bevel looks, yet.

The 45 degree spine-off stone honing is just a technique to knock off the corner of the bread knifed edge. Just break the corner to save some time. Perhaps it may have confuse the issue more than it helped, it is completely optional and you do not need to do it. You can just hone on the 1K and achieve exactly the same results. It is just how I do it, not mandatory.

Don’t worry about the toe and heel at this point, wait until we are honing with the spine on the stone, we can adjust contact on heel, toe or other spots with different strokes, techniques and added pressure if needed.

Don’t worry about how straight the edge is or that it is not centered, until we are honing on the stone, remember you were free hand honing the blade.

Also you do not have to breadknife, you could have just honed on the 1k and eventually straightened the edge, removing exactly the same amount of steel. The edge will straighten out when we hone it, or we could curve in in a smile depending on the stroke we use.

And remember this is not just a regular honing, there has been a lot of repair work and you are working on an old neglected blade, that is probably is not straight. But it will shave when we are done with it.

Begin honing on the 1k with 2 pieces of tape, and do circles in sets of 20 then the other side. Do sets of 20 until the bevels meet.

-

The Following User Says Thank You to Euclid440 For This Useful Post:

pcm (12-01-2015)

-

12-01-2015, 11:55 AM #38

Thanks Euclid440! I'll give this a shot on Thursday night and report back the results!

Appreciate the clarification, as I wasn't sure how "correct" I needed to get things at this point. I understand now, that we're just cutting off (sic) some time with the honing.

Fortunately, I've never honed a knife either, so I don't have any preconceived notions of how things should look or be done. Regards,

Regards,

PCM

-

12-01-2015, 12:13 PM #39aka shooter74743

- Join Date

- Sep 2009

- Location

- SE Oklahoma/NE Texas

- Posts

- 7,285

- Blog Entries

- 4

Thanked: 1936

From what I can tell, you jumped from the cliff into the ocean without knowing how to swim. Call me what you wish, but I personally feel that you will learn to hone quicker and easier if you learn to touch up a razor than try to learn on a older razor that may have issues. Touching up a razor teaches you pressure and familiarity with the stones. Lastly and most important, find a honing mentor...it will shave you a LOT of frustrations along the way. These guys will give you the right information, no doubt. Taking their written words and intent and applying it to the stones is the trick.

Southeastern Oklahoma/Northeastern Texas helper. Please don't hesitate to contact me.

Thank you and God Bless, Scott

-

12-01-2015, 11:51 PM #40

I have four razors right now. Two are new from SRD, one vintage from classifieds, and one I just bought from antique store. The Dovo, I had dinged in the sink, and did minor honing (successfully) to correct. Since then, I sent it in for the free honing.

The vintage, I've used a lot and have touched up with the 4K/8k/12k, my first real honing. It's not a perfect blade by any stretch, some minor issues, but with help through SRP, I was able to hone it and have used it about 20 times since.

The Boker, also from SRD, I've been using, until I honed the vintage. I plan on using it a bit more, and then send it in too for a free hone.

I specifically got this Henckels so that I could do a full on honing, with the hopes that it could be shavable in the end. It's a $20 experiment. I really jumped in on this one, and found out that it needed repair, so I've been diligently going through the process, with loads of help.

Maybe I'm been optimistic, but I think this is doable. I'm taking my time, absorbing the feedback, and working through things. Maybe not the best razor, but I've been learning a lot, IMHO. I'll probably never get it perfect, but I don't expect to. I'll declare success, if I get this in a shavable state, even if that is not a long lasting edge. Better this blade, than the two new ones, or the vintage, which I happens to be my favorite.

I did look for mentors at one point, but don't see any in NH, southern ME/VT, or eastern MA. So I'm trying the forum route. I'm sure hands on help would be great, just don't think that is possible in to area.Regards,

PCM

99Likes

99Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote