Results 1 to 10 of 85

-

11-15-2015, 11:53 PM #1

Second try at honing...seeking opinions/suggestions...

Second try at honing...seeking opinions/suggestions...

Hi, I picked up a JA Henckels razor that had a reasonably sharp edge, but lots of dings and such. I mentioned it here http://straightrazorpalace.com/razor...ggestions.html

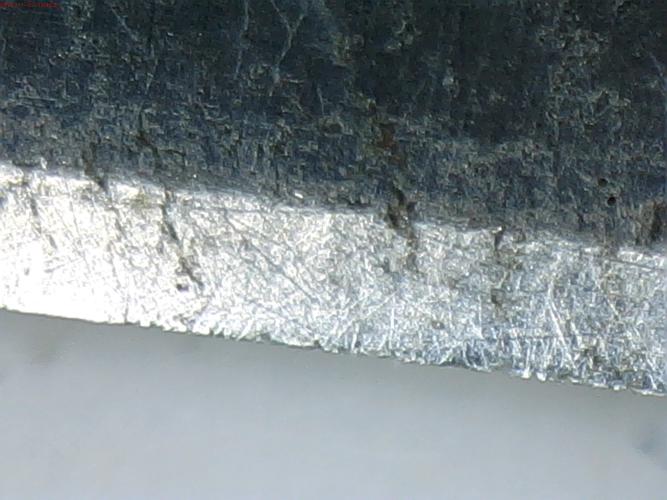

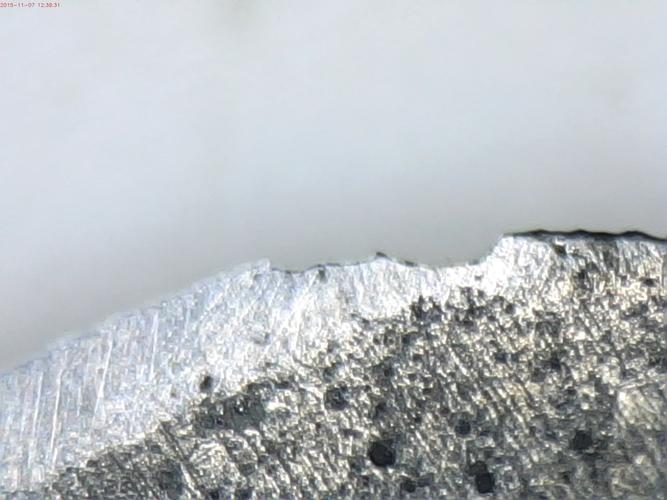

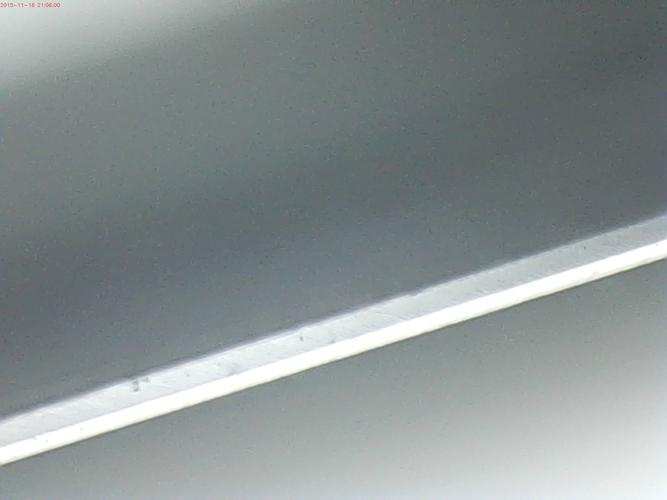

Here are some original condition pictures of the bad spots:

The bevel was about 1.5mm wide. The heel had the worst ding, about 2mm long. Same with the divot seen. It cut arm hairs on the front half of the blade. But lots of nicks. It has some black spots, several on the bevel.

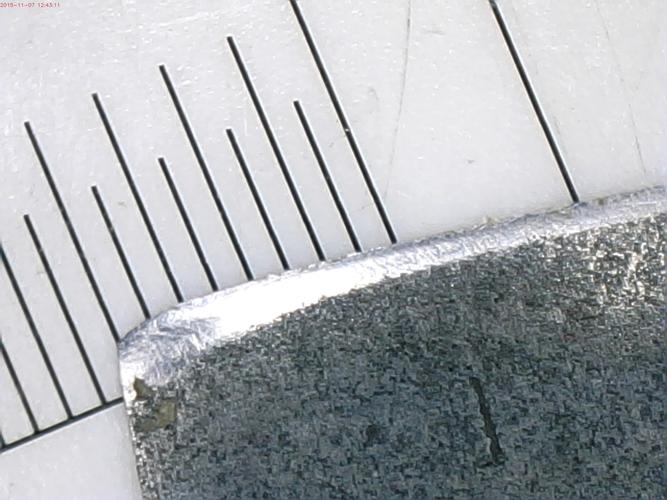

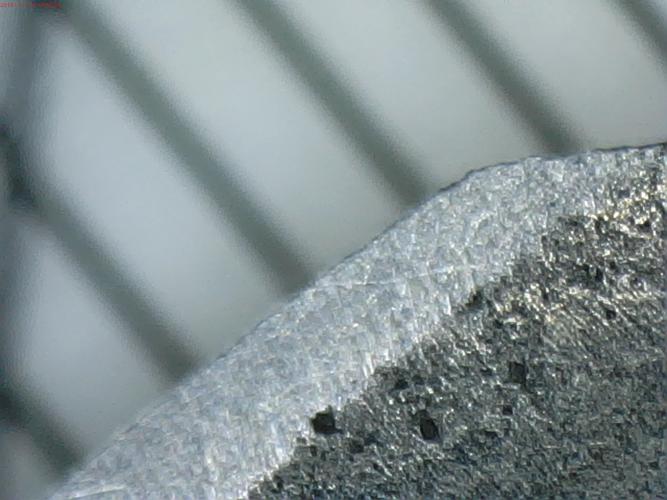

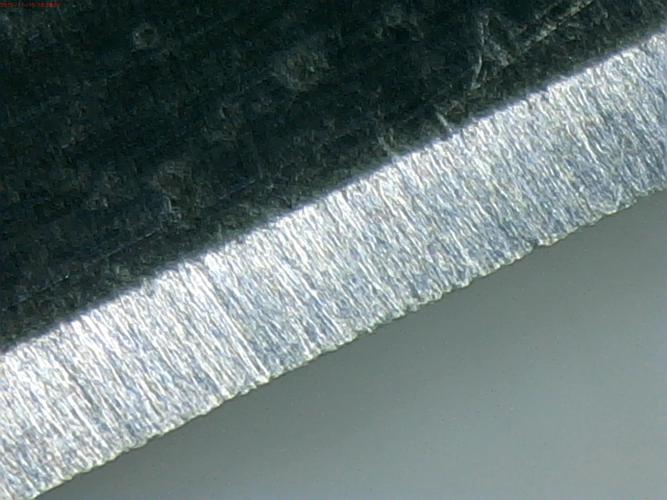

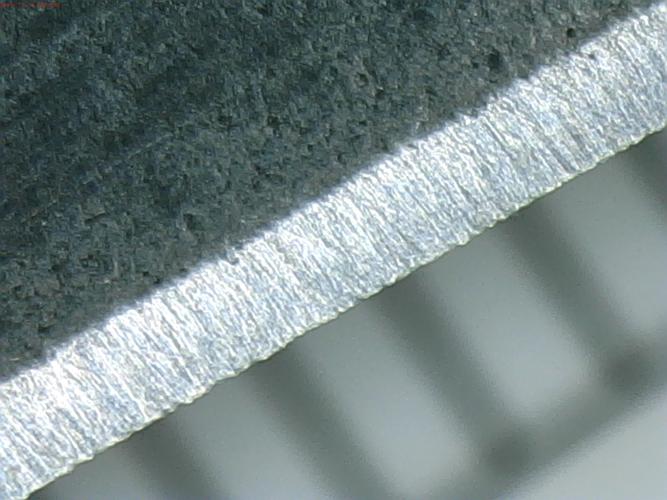

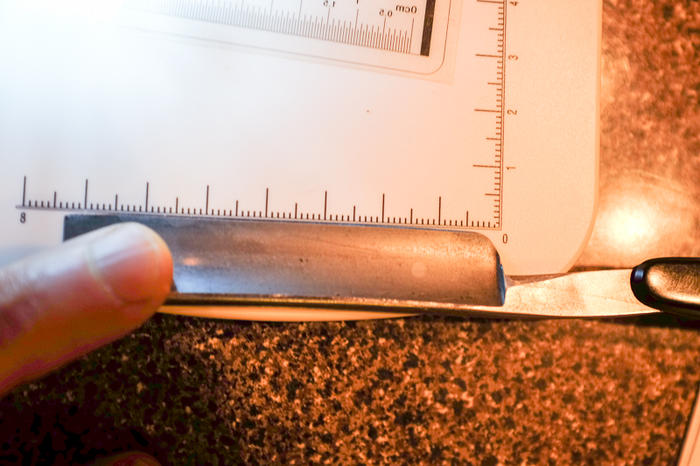

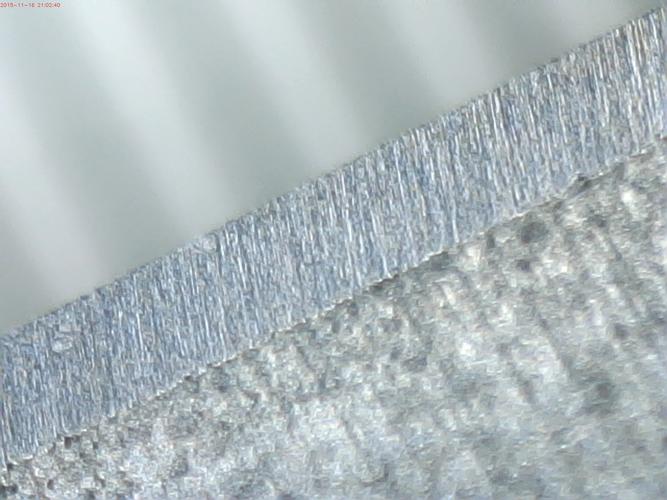

This is the second razor I tried honing, with the goals to be practice honing, and possibly get it in a shaveable state. Per some suggestions in the original thread, I put on 3 layers of tape, and did circles on the 1K Norton, until the dings were out. The one on the heel was still there a bit, so I switched to one layer of tape and honed more. Here's what I have so far:

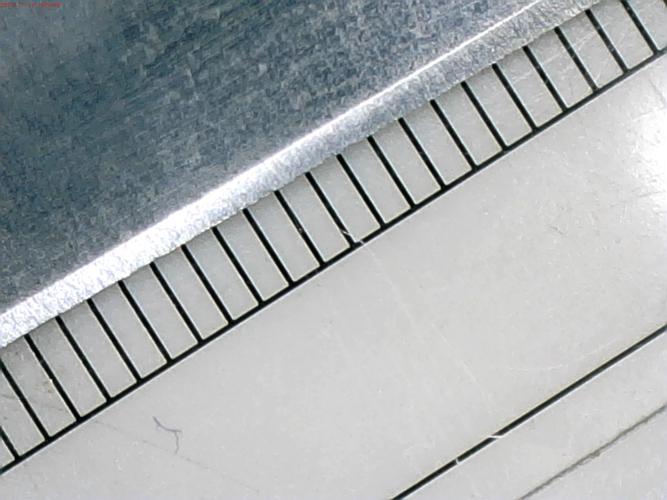

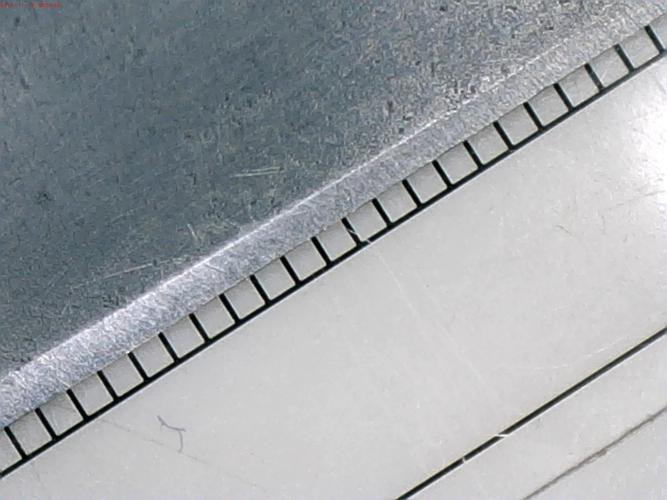

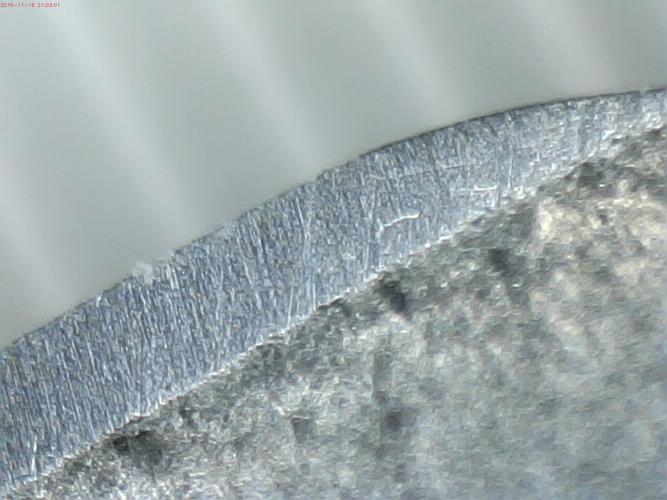

The bevel width on one side is pretty even. A bit narrower at the heel and wide at the toe, except at the very toe, where the old bevel was pretty wide. The new bevel hasn't reached up that far. On the other side, the bevel seems even, except near the toe, where it gets a bit narrower, and again the old bevel is wide at the very end.

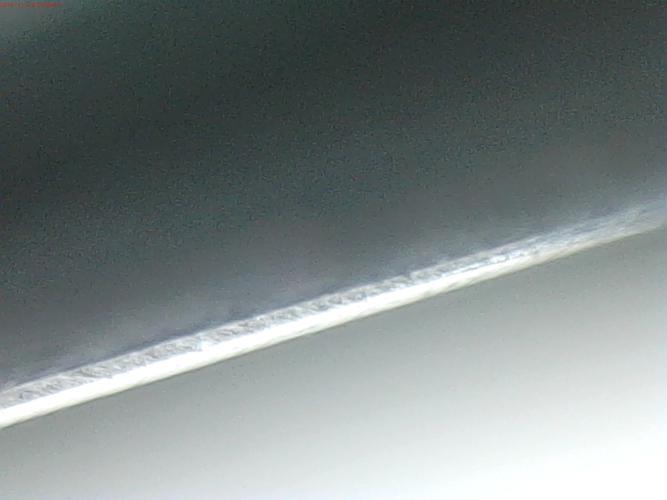

The heel (first shot) seems pretty good, somewhat of a divot left, but I think it is past the edge. The middle looks pretty good, maybe a bit jagged? It's pretty high magnification. The toe (middle, and last two), you can see the new bevel is not as wide.

Thoughts on the bevel?

Looking at the edge head on, it seems to meet well. I don't see any shiny spots along the edge.

Should I proceed to 4k/8k, and then 12k, or do I need more work here?

Thanks in advance!Regards,

PCM

-

11-16-2015, 04:05 AM #2Senior Member

- Join Date

- Apr 2012

- Location

- Diamond Bar, CA

- Posts

- 6,553

Thanked: 3215

Do the bevels meet? You move up when the bevels meet, are flat from heel to toe and you have an even stria pattern. Get the stria all going in one direction.

What are you honing on? The stria pattern looks rough and does not look like you are honing to the edge at the tip. Try inking the bevel.

You are using tape on the spine, right?

You will have to reshape the heel.

You may want to clean that razor, all that rust will end up on your strop.

-

11-16-2015, 11:25 AM #3

Thanks for the comments!

The bevels seem to meet. I'll check the stria pattern across the whole edge, but mostly, it is the same. The toe is one area where the previous honing is much wider that what the new honing is.

I'm using a Norton 1k right now. I tried a little added pressure at the toe end, but not sure if I did it long/hard enough. Will try inking. Any suggestions there?

I had 3 layers of tape for a while, whent he new bevel was about 1/2 way up from the old bevel and then switched to 1 layer and honed until the bevel was as wide as before and it seemed like the dings were gone (all but a tiny amount at the corner of the heel.

Can you elaborate on "you will have to reshape the heel"? Not sure how to do that.

Yes, it was suggested to use 0000 steel wool and then metal polish. I did a bunch of rubbing with steel wool last night (after the photos). I had some stainless steel polish, but it doesn't look like what I need. It is for cleaning appliances and is a form. I have to look around more for some polish. I think I have chrome polish (for car). Any suggestions here? Doing all this by hand.

Thanks!

PCMRegards,

PCM

-

11-16-2015, 04:43 PM #4Senior Member

- Join Date

- Apr 2012

- Location

- Diamond Bar, CA

- Posts

- 6,553

Thanked: 3215

Did you lap you stone flat and bevel or round the edges. The scratch pattern does not look like a 1k pattern.

You may want to re-lap it.

The heel has developed a corner and will turn into a hook either way it will cut you, shape it to look like it did before you started, tracing a dime or penny on the heel with a sharpie is a good template. You will have to re-hone the heel.

You can re-shape with a diamond plate or file or low grit stone. The bottom side of your 1k will work if you have nothing else.

Some photos of the razor, spine and heel close ups, may show some other issues, something is going on, other than technique.

Put some ink on the bevel, you are not honing to the edge.Last edited by Euclid440; 11-16-2015 at 04:46 PM.

-

11-16-2015, 11:41 PM #5

I lapped the 1k Norton, using the diamond plate, before starting. I haven't rounded the edegs. What should I use to do that?

The heel, before I started, is shown in the first set (photo 5) and had a 2+ mm long ding that was about 1/2mm deep, right on the corner of the heel. With honing I've got it down to the first photo, in the second set.

I have a 220 (other side of 1k Norton) and the diamond plate. Do I file it right on the edge of the blade?

I'll check with marker, but it does seem to hone right to the edge of the bevel (as I notice it change from 3 layers to 1 layer and move up, with a different look to the newly honed area), except at the very toe. That had a large bevel (photo 2 in first set). It is not honing that area hardly at all, and I'm not sure what to do there.

I'll do more photos. The spine had some wear, and there were several dings, with the heel the worst. There was a divot, about 1/3 from the toe, shown 3rd in first set, that seemed to hone out.

There numerous spots of black, largest near the toe, on one side.

My goal here is to use this blade to practice honing, and hopefully, bring it to condition to shave with. It it ends up with a lasting, reasonable edge, great. If not, it was a $20 learning exercise.

I'll ink and hone and then post (hopefully tonight).

Thanks for the comments/suggestions!Regards,

PCM

-

The Following User Says Thank You to pcm For This Useful Post:

beluga (06-14-2018)

-

11-17-2015, 12:12 AM #6Senior Member

- Join Date

- Apr 2012

- Location

- Diamond Bar, CA

- Posts

- 6,553

Thanked: 3215

So there is no reason to believe it will not take an edge, and should shave just fine, again some photos of the whole razor may give up some more information.

Either bevel the edges at a 45 degree, an 1/8 in bevel is fine, angle or round them over with the diamond plate, use lite pressure. If you donít bevel or round the edge, each lap as the edge slides over the edge, you will undo all the even honing you are doing on the stone face and bevel.

Yes reshape the heel with the diamond plate in the rounded shape it was in before the chip. Take your time the metal is actually pretty thin. Have you honed on the diamond plate?

If not, donít, it will only cause you more issues down the road.

No matter how many layers of tape you are using, you still have to hone to the edge. Some of the photos show stria that is not reaching the edge, and you need a flat bevel from heel to toe and from the edge to the top of the bevel, and that meet at a sharp edge, that is a fully set bevel. Until then you will be wasting your time moving up to the next stone.

This thread, ďMy first honingĒ is packed with good information and post 41 has photos of the edge, looking straight down on it with magnification. There are photos of the edge almost set and fully set. Until you can look at the edge and not see any shiny reflections, your bevels are not FULLY meeting.

-

11-17-2015, 12:49 AM #7

I've never honed with a diamond plate. Here's what I did so far tonight...

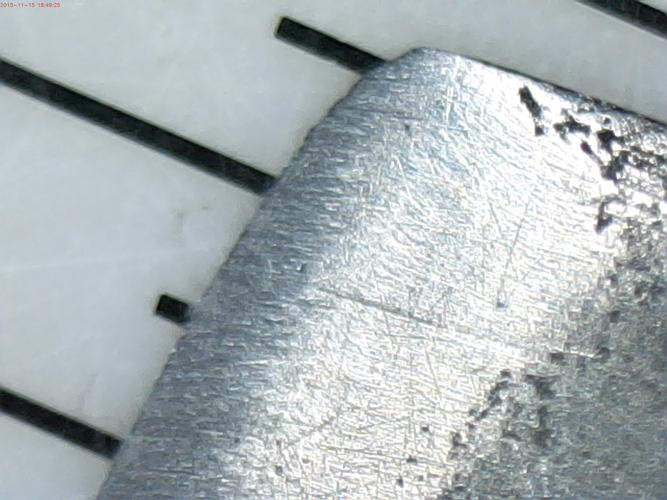

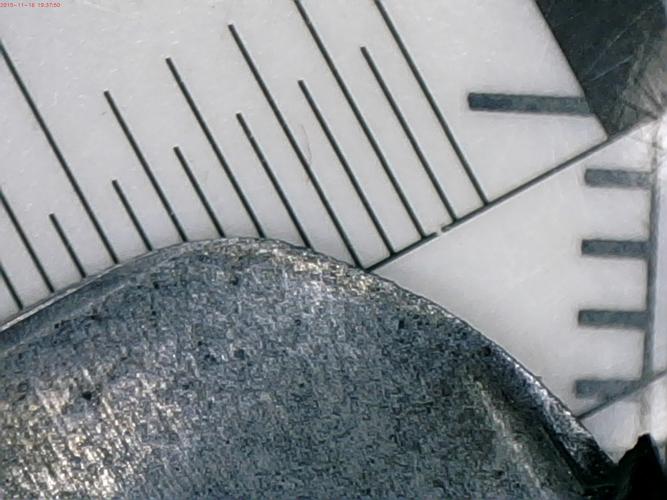

Did more steel wool (0000) and found some silver polish we had to try to clean it up some. Then, took the side of my Norton 1K and worked on rounding the heel. Here's what I have now (marks are 1mm):

I took some pictures of the blade, so you can see the curve of the spine, the wear, and the curve on the blade. It is tapered on each end. It's a little blurry on some shots (shooting one handed), the black spot in the middle of the blade was tape that I didn't wipe off:

How will that affect the stroke I need to use?Regards,

PCM

-

11-17-2015, 01:02 AM #8

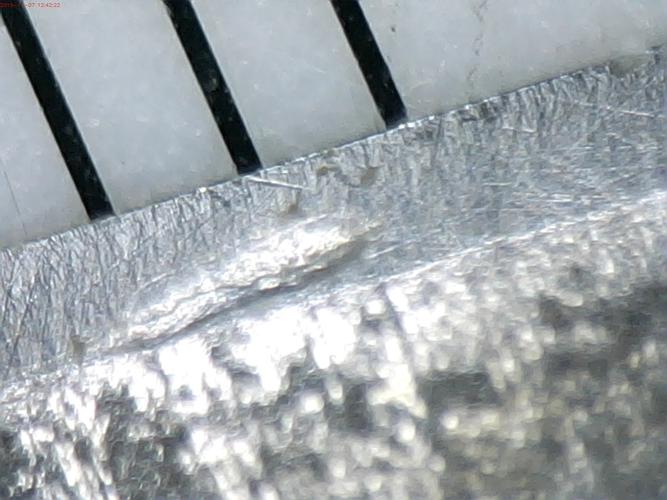

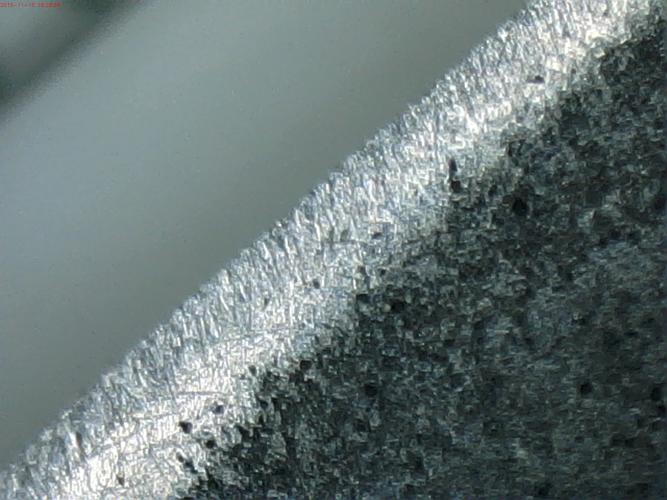

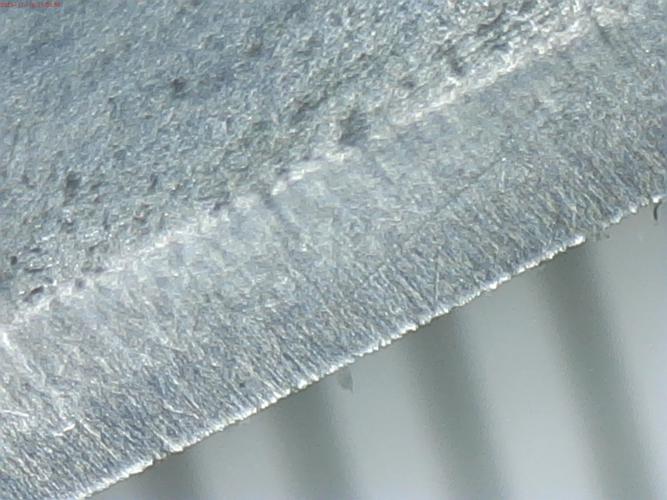

Here are views of the edge on each side, at lower magnification, after the first honing passes I did yesterday, and after I cleaned with steel wool (so I may have perturbed the edge a bit). It looks like there is a parallel scratch towards the heel.

Regards,

Regards,

PCM

-

11-17-2015, 01:17 AM #9

Oh, I relapped the Norton 1k again. It seemed pretty good, just a little higher on the outside edges. I had an old knife hone and I did a bevel on the edges of the 1K (will do that on the others)

I put on 3 layers of tape and did some X strokes with the 1K. I can see the different angle, about 1/2 way up the old bevel, but not at the toe of the blade. Probably 1/2-3/4" has almost no coverage.

Suggestions on how to proceed with that condition?

Thanks!Regards,

PCM

-

11-17-2015, 02:18 AM #10

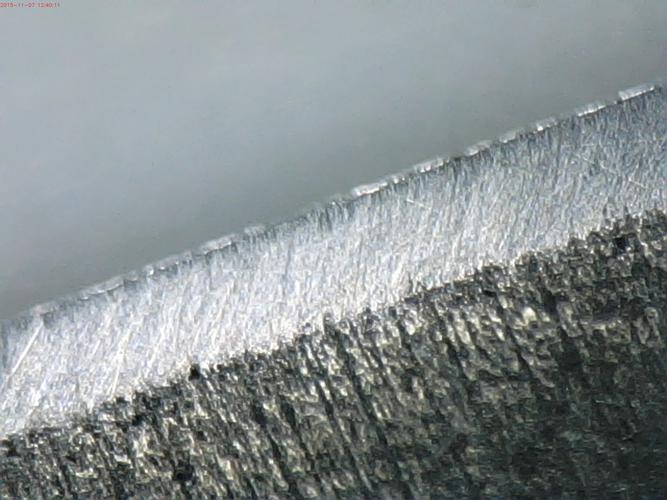

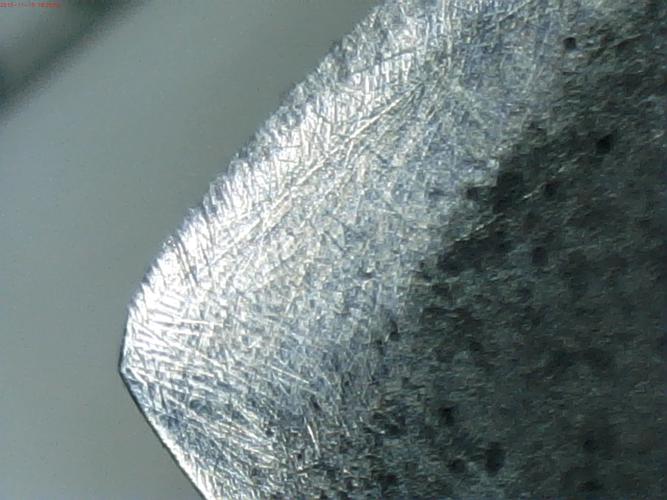

I honed with 3 layers (started with circles, then did X pattern with moderate pressure, and finally lighter pressure) and looked at the edge. Was able to get rid of the large parallel scratches I had before easily. There are a few from the circles. Most seems OK. The toe is the only part where there is little bevel. Looking down on the edge, it seems to meet pretty good for all but the toe.

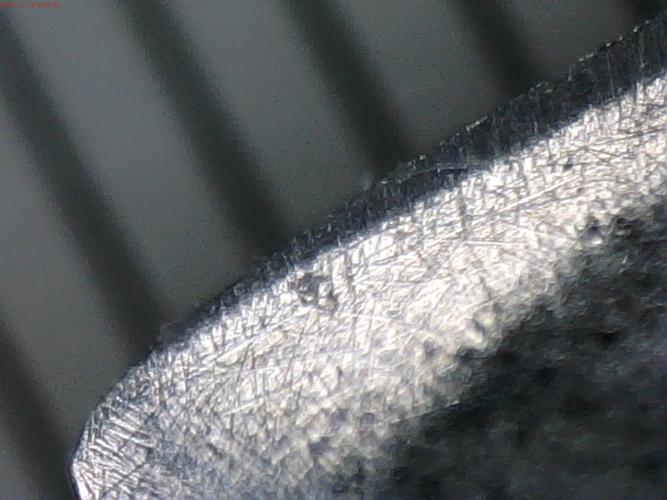

Here are some shots at high resolution:

Edge (middle is near toe) ^

Mid ^

Toe ^

Heel ^Last edited by pcm; 11-17-2015 at 02:23 AM.

Regards,

PCM

99Likes

99Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote