Results 1 to 10 of 38

Threaded View

-

01-16-2017, 09:44 PM #1

My first try at setting the bevel

My first try at setting the bevel

Story behind this SR:

BeeJay honed me two razors and gave me one to try out myself.

Some pics of the work done:

1) Unpinning failing as usual. This is the only picture I have where you can see how the blade was:

BJ said:

I decided to leave that work for later.Sometimes you can fix celluloid with acetone.

Acetone will actually melt celluloid. The idea is to use as little as possible so that the scales don't fully melt. Clean the area very well and put just a bit of acetone on either side of the crack with a Qtip. When the celluloid starts to soften, hold both pieces together and they will eventually harden as one piece.

It's a very strong repair if you get it right. The trick is to use the right amount of acetone.

2) Evaporust

I started using this product on every SR which has some rust on it.

Here's after 4-5hs:

The blade looks dark, but it goes away with some sanding

3) After 180-400-600 Sanding:

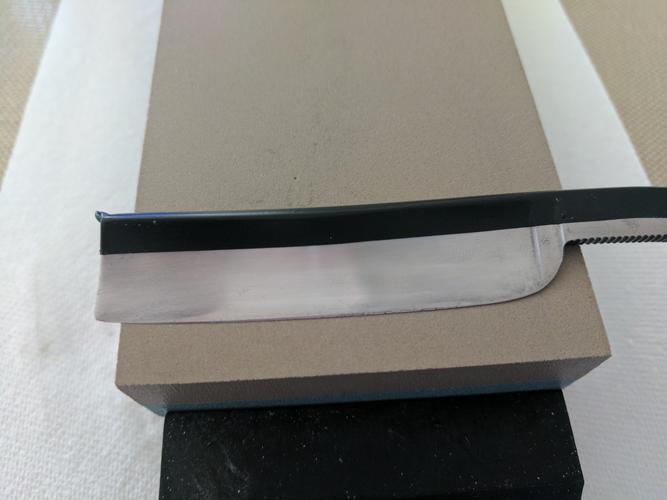

4) I taped the blade and this is what they look before:

5) After some X strokes

I doubt you can say much about the pictures but I would like to ask some general questions:

1) At the beginning, the toe and the heel were not getting a bevel at all. I guess that's my X stroke technique fault. The last strokes I put some pressure on the toe and on the heel and it got a bit better. Is that ok?

2) Does the "height" of the bevel matter? I noticed that the one I did is thinner than most of the SR pro honed I have. I was going to keep going but decided to stop and ask first.

3) The bevel I have is already shaving hair from my arm. Is that enough to stop?

4) I need to get a zoom/magnifying glass. Any recommendation?

5) What do you think it should be my next step? My stones are: 200/1k Norton, 4k/8k Norton, 12k Naniwa

Thanks for reading!

56Likes

56Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote