Results 1 to 10 of 144

Thread: Dovo’s honing method

Hybrid View

-

04-29-2021, 06:19 PM #1Senior Member

- Join Date

- Sep 2020

- Location

- Austin, TX

- Posts

- 653

Thanked: 56

Yall all know that I don't claim to be an expert in this in any way. But what it seems like razorfranken81 is saying is that Soligen razors have always been ground and honed on a concave stone to make a convex edge. But also that the masters of the craft have all retired and are not producing the quality that they did in the glory days. It kinda seems like the argument is the level of quality degradation.

There is a small debate about the edge shape, and I certainly don't know the science of the flat, concave, and convex bevels. But I would think that with the microns we are dealing with, a fine shaving edge (at least for 99% of us) can be produced flat, concave, and convex. So here again, it seems to come back to whether or not the edge is shave ready regardless of shape. If I pulled out my first razor out of the box and it tugged, pulled, and hurt I would have thought "I guess that's why they don't use these any more" and had a fancy letter opener and a Mach III razor or stuck with the beard.If you're wondering I'm probably being sarcastic.

-

04-29-2021, 06:41 PM #2At this point in time...

- Join Date

- Jun 2007

- Location

- North Idaho Redoubt

- Posts

- 26,987

- Blog Entries

- 1

Thanked: 13234

Last edited by gssixgun; 04-29-2021 at 06:45 PM.

"No amount of money spent on a Stone can ever replace the value of the time it takes learning to use it properly"

Very Respectfully - Glen

Proprietor - GemStar Custom Razors Honing/Restores/Regrinds Website

-

04-29-2021, 06:58 PM #3Senior Member

- Join Date

- Sep 2020

- Location

- Austin, TX

- Posts

- 653

Thanked: 56

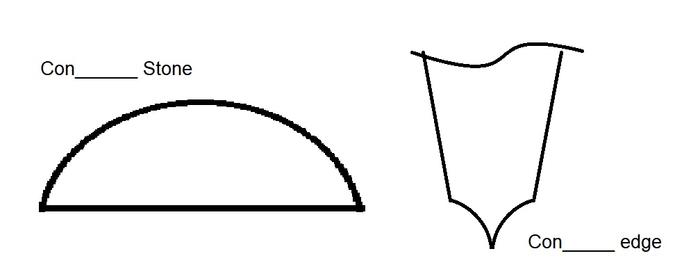

See, I clearly don't know how concave and convex is defined. After reading so many of these I am not entirely sure there is agreement.

I totally understand the commercial aspect of the plates/stones/etc. Which is why I find it interesting, but for my face will use flatish stones that start to dip in the middle with use until I can't get a comfy edge and flatten it again.If you're wondering I'm probably being sarcastic.

-

04-29-2021, 07:16 PM #4At this point in time...

- Join Date

- Jun 2007

- Location

- North Idaho Redoubt

- Posts

- 26,987

- Blog Entries

- 1

Thanked: 13234 "No amount of money spent on a Stone can ever replace the value of the time it takes learning to use it properly"

"No amount of money spent on a Stone can ever replace the value of the time it takes learning to use it properly"

Very Respectfully - Glen

Proprietor - GemStar Custom Razors Honing/Restores/Regrinds Website

-

04-29-2021, 07:34 PM #5Senior Member

- Join Date

- Mar 2012

- Location

- Thunder Bay, Ontario, Canada

- Posts

- 17,251

Thanked: 3222

Personally, I don't care how a razor maker hones the final edge so long as my face says it is shave ready. I also don't care if the razor comes with a shave ready certificate from the maker for the same reason. When the consensus in the shaving community says your edges are sub par then they probably are. The only way to fix that is correct the problem at source and supply decent edges. If you can't do that then you'll eventually lose business no matter how you whine on about honing.

BobLife is a terminal illness in the end

-

04-29-2021, 07:44 PM #6Senior Member

- Join Date

- Sep 2018

- Location

- Palm Harbor Fl

- Posts

- 371

Thanked: 48

The most ridiculous part of it all imo is someone saying these guys "know" what theyr doing and we are not smart enough to realize we are wrong. Show me the money! Is what I say. Lead by example then and put a decent edge on. Or say they need honing before use as has been proposed by many as well.

-

04-29-2021, 08:09 PM #7At this point in time...

- Join Date

- Jun 2007

- Location

- North Idaho Redoubt

- Posts

- 26,987

- Blog Entries

- 1

Thanked: 13234

Just to clarify

There are two issues being discussed here,,

#1 Dovo and most other Production razors are simply NOT shave ready, nor have they really ever been, in the last few years Dovo has become so bad that they are sending out Frowned razors .. This is unacceptable considering when a new guy sends his razor out to be fixed it voids their warranty.. They also don't see this as out of spec and won't replace the razor if the new guy tries.. I have even gone so far as to give these new guys' the pics of their razors with the frowns to send to Dovo before I fixed them to see if they would replace it..

I made a point of it a few years ago, at that point in time Jarrod took it upon himself to defend Dovo and attack me, using my name to garner hits on his site and YouTube

Basically he was saying "Don't believe your lying eyes" as to what the Dovo Honing vid was showing between the Platen grind and the Convex hone

#2 Jarrod once again doubled down by making his junk science claims about Convex Honing and used my name along with Steve and Marty to garner more hits to sell this idea, Basing it on this statement "The Solingen Masters have been using this technique for years"

I fired back with "If and when those "Masters" can produce a Shave Ready edge and no frowns I MIGHT start to listen" Until then Learn to hone and stop the BS...

Now we all of a sudden have Mysterious German guys hitting the shave fora with the same style of writing and same junk science

As I explained earlier no more nicey nice... I am going to call it as I see it.."No amount of money spent on a Stone can ever replace the value of the time it takes learning to use it properly"

Very Respectfully - Glen

Proprietor - GemStar Custom Razors Honing/Restores/Regrinds Website

-

04-29-2021, 07:42 PM #8Senior Member

- Join Date

- Sep 2020

- Location

- Austin, TX

- Posts

- 653

Thanked: 56

Honestly, only kinda. I mean, I think you experts know what the definition is, but I am not sure everyone on the internet does.

The way a razor is discussed it usually seems like in my little picture it would be a convex stone with a concave bevel. And, the way you describe Jarrod's plates, I think you would agree with that, right? But, I have a pair of scissors with a "convex bevel" that seems to be the opposite of that.

Edit: Per Steve's picture I guess I don't even know which way you con____ the hone. I should have just listened to me yesterday and stayed out of this. Sorry.Last edited by planeden; 04-29-2021 at 07:48 PM.

If you're wondering I'm probably being sarcastic.

-

04-29-2021, 07:00 PM #9Senior Member

- Join Date

- Sep 2018

- Location

- Palm Harbor Fl

- Posts

- 371

Thanked: 48

-

04-29-2021, 07:25 PM #10At this point in time...

- Join Date

- Jun 2007

- Location

- North Idaho Redoubt

- Posts

- 26,987

- Blog Entries

- 1

Thanked: 13234 "No amount of money spent on a Stone can ever replace the value of the time it takes learning to use it properly"

"No amount of money spent on a Stone can ever replace the value of the time it takes learning to use it properly"

Very Respectfully - Glen

Proprietor - GemStar Custom Razors Honing/Restores/Regrinds Website

327Likes

327Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote