Results 91 to 100 of 185

Thread: Learning Jnats with Microscope

Threaded View

-

02-18-2021, 11:07 AM #1

Learning Jnats with Microscope

Learning Jnats with Microscope

Hi to all SRP guys!

After posting something "random" in another thread (Hone of the day... where I got a great help from Euclid440 ) I decided to start a new one, where to put my experiences with Jnats with the aid of a (cheap) USB Microscope. Nothing new of course, but just the learning curve of a newbie, both at honig and with Jnats. Hope images, experiences and comments will be helpful to other newbies (and myself of course) to understand something more about this engaging topic.

) I decided to start a new one, where to put my experiences with Jnats with the aid of a (cheap) USB Microscope. Nothing new of course, but just the learning curve of a newbie, both at honig and with Jnats. Hope images, experiences and comments will be helpful to other newbies (and myself of course) to understand something more about this engaging topic.

First: I'm new at honing (about six months and 20some razors honed & touched up)... but wanna grow always more.

Second: Microscope doesn't hone. It's just a tool which helps to understand what I'm doing & how the stones work. It doesn't says if an edge is sharpen enough or if the shave will be smooth but, it can act as a visual aid to correlate phisical sensations to what is happening on the bevel and the edge. I.e. when we test (fingers, thumbnail test, tree topping hairs, HHT) we can try to see if what we feel is related (and how) to what we see. We can try to understand if a particular finishing aspect gives us a more or less smooth shave. Needless to say, it use is essential to share what's happening with other people. Actually I'm still working at finding the right background to put the razor. This time I used a dark blue foam pad, but was not much satisfied.

Third: Actually I've 3 small Jnats: Aiiwatani Karasu - Nakayama Kiita Koppa and Ozuku Koppa. All in the low price range, but already better than many other stones (or, at least, that's what my skin says ). Plus some Tomos & Naguras I will test day by day. Microscope will help me to understand how these ones work.

). Plus some Tomos & Naguras I will test day by day. Microscope will help me to understand how these ones work.

So, let's start with yesterday's honing session. Today it delivered a very, very close shave. It was quite smooth too.

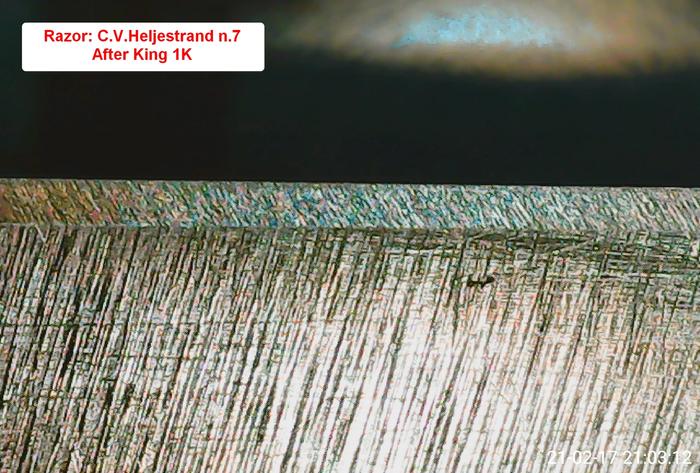

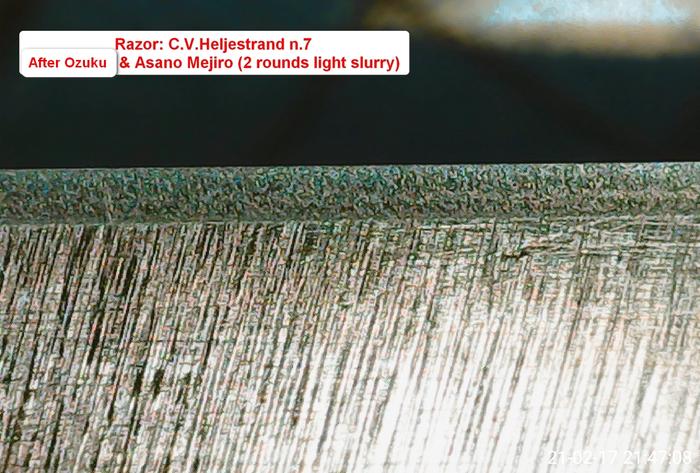

Razor: C.V.Heljestrand n.°7 - Eskilstuna - 5/8" 1/4H. I've honed or touched up it previously, but never got the right balance in keenes/smoothness.

This time I killed the edge and used (with 1 layer of Kapton Tape): King 1K - Naniwa Super 3K - Ozuku Koppa - Asano Mejiro Nagura (first time I used it) - I jointed the edge some times during the various phases.

Last edited by Skorpio58; 02-18-2021 at 11:17 AM.

I know that I don't know (Socrates)

-

The Following User Says Thank You to Skorpio58 For This Useful Post:

ischiapp (03-18-2021)

211Likes

211Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote