Results 1 to 8 of 8

Threaded View

-

01-29-2025, 05:25 AM #1

Sharpening My First Gold Dollar Razor

Sharpening My First Gold Dollar Razor

Hello! I am back after a year-and-a-half long hiatus. When I left off, I was struggling to get a good shave out of my Dovo Colonel Conk, and having similar trouble with an expertly honed vintage razor which was gifted to me by @PaulFLUS. Thank you Paul for the razor!

In the mean time, @CrescentCityRazors shipped me a couple blocks of acrylic as well as some lapping film, which is not available for purchase where I live. Thank you Crescent for the finishing stone!

While we're at it, I should also shout out @gssixgun for a zoom lesson some time ago. It was really insightful! My apologies for taking this long to get back to honing.

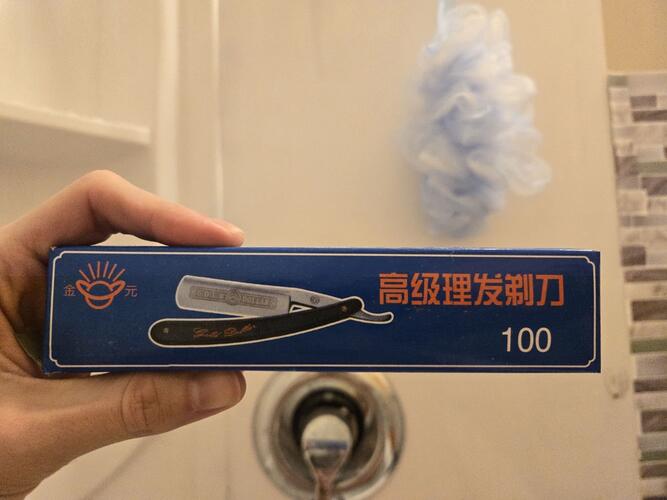

The last thing I did before I left off was order a stack of dirt cheap Gold Dollar straight razors from Aliexpress.

Now, when I say dirt cheap, I mean dirt cheap, I ordered them for approx. $10 CAD per razor, and then during checkout they got randomly discounted to around $1.50 per razor. They must have really wanted to get rid of them! I can see why:

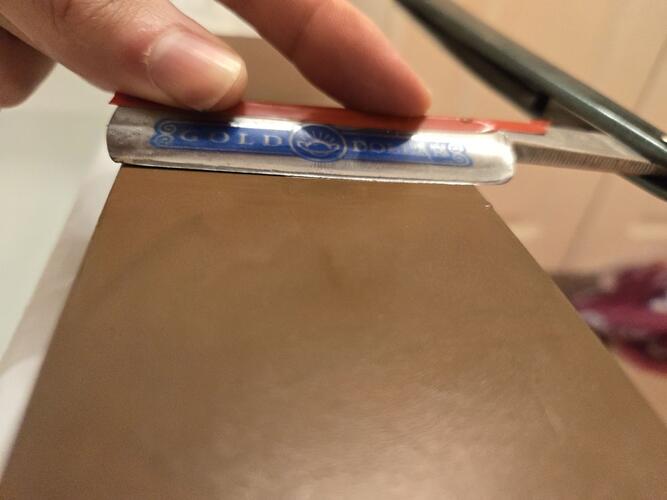

This thing was jagged. You'd probably be better off shaving with a bread knife, frankly. The deepest chips looked to be approx. 1/32" in depth, and there was a lot of them

At least it seemed to sit pretty flat on the hone (that is, only if leaning on the blade, if sitting on the spine it was quite uneven indeed.

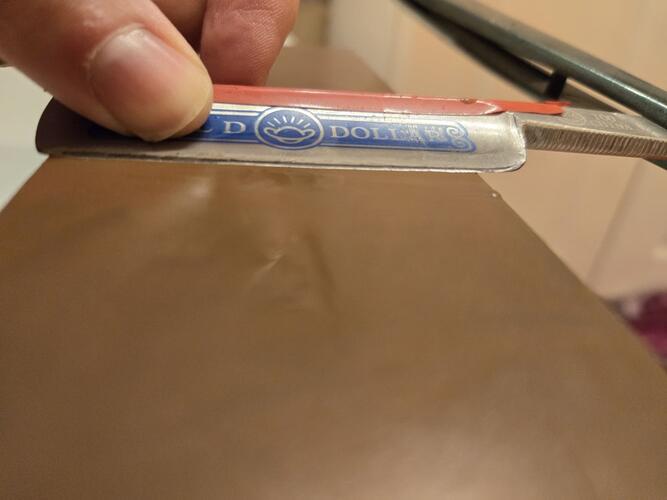

I wrapped the spine in a single layer of electrical tape, painted the bevel with permanent marker, and went back and forth for a few strokes. It seemed to wear pretty evenly across the length of the bevel, however it was readily apparent that these chips were not going to disappear without a fight.

I tried breadknifing against the corner of my hone, which in hindsight doesn't seem to make a lot of sense to do. I think to quickly get chips out, you would probably want to swipe it back and forth against a flatter and rougher surface, like a 220 grit diamond hone perhaps. It did not seem to do anything to make the chips go away. After doing some quick googling, I saw multiple people suggest that you should stop breadknifing once the chips are at approx. 1/32" depth anyway, as you would be wasting metal if you go any further than that. Since my chips were already there, I decided to simply hone them out the long way.

I set a stopwatch and did rolling X-strokes until there were no longer any visible chips. It took approx. one hour at my speed to get them all out. That said, I am inexperienced and was going quite slowly at first, using a technique involving both hands, rolling light pressure from one hand to the other as I went down the hone. As the hour progressed, I made up my mind that this technique is not ideal, as it seems to have a high risk of cutting one of your thumbs open every time you rotate the blade, not to mention the temptation to lean on the razor a bit, applying far more pressure than necessary. By the end, I was using a one-handed technique, quickly swiping back and forth across the hone in a sort of rainbow motion. This feels much faster and lower risk, though also less accurate.

After some time, I tested the length of the blade against my arm hair, all the way down on both sides. It seemed to be doing an okay enough job in all areas, so I moved onto the 4K. This time, I continued honing until the relatively deep grooves from the 1k disappeared. I could not really tell if I was done or not, as it seemed to have a bit of a double bevel, which would make sense considering the electrical tape on the spine. I'm not sure whether or not it actually did have a double bevel, as by the time I finished on the 8k, most of the blade seemed quite shiny.

Upon closer inspection, there did seem to be a lot of scratches left. My eye is not well trained, but they appeared to be mostly 4k scratches with the odd 1k scratch leftover.

After finishing up on the 8k, I went on to the microfinishing film (please don't kill me if that's the wrong word for it, as I recall there being many very similar looking films with different names, some of which are not appropriate for straight razors.) I lapped it while holding the block in my hand for approx. 5 minutes, then went on to the canvas strop, then the leather strop, skipping the pasted strop in the process.

I'm not sure how great of a job I did overall, but it seems to shaving down my arm quite effortlessly all the way down both sides of the blade, so for now I'll call this mission accomplished!

The real test will be in a couple of days when I try shaving my face with it for real. Time will tell whether it is my ego or only my face which gets beat up

Thank you for reading!Last edited by rickytimothy; 01-29-2025 at 05:29 AM.

8Likes

8Likes

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote