Results 1 to 10 of 32

Thread: New member - challenged honing

Hybrid View

-

08-04-2010, 12:34 AM #1illegitimum non carborundum

- Join Date

- Jan 2008

- Location

- Rochester, MN

- Posts

- 11,544

- Blog Entries

- 1

Thanked: 3795

-

08-04-2010, 12:44 AM #2

eddy when you say it looked good after 1k did it look like that?

I bet you have a good bit more corrosion to get through.

while waiting for 4k spend some time correcting those chips

-

08-04-2010, 12:57 AM #3

Ron i agree with you .

In your case 8k stone hasn't done it is job yet .

he should stay in 8 k longer he has been.

In any way the picture which says after 8k is not looks like 8k edge.

There is no way we could say 100% what is the reason until he gives us more information what he has done how many strokes on each stone, how much pressure etc.

difficult way to go.

i think the best will be he gets 4 k and properly honed blade.

watches the edge how should be and hones his own blade.

i hope he is not changed temper on the blade while he was cleaning with Dremel

.

-

08-04-2010, 01:12 AM #4

Man you are taking a VERY big bite at once. I have been shaving with straights since March of this year and have yet to even purchase a hone of any kind. Some people may think that this is slow but i feel that i need to concentrate on my shaving and stropping technique and get them reasonably passable before i throw, what i feel, the hardest thing about straight razor shaving in the mix. I am lucky to have some one in the same town that belongs to this society and is somewhat willing to hone my razors for me. I suggest, as others have in this post, that you send the razor to a person in the classifieds that can hone it for you and take out all the guess work while you are still learning to shave, lather, stretch, strop and learn all the different directions that your whiskers grow in. That is just my humble opinion.

-

08-04-2010, 01:39 AM #5Member

- Join Date

- Aug 2010

- Posts

- 34

Thanked: 4

Guys I have given this blade a lot of honing. I think that with the 1k side I have worked through all the corrosion. At the beginning I even had little tiny holes that you could see through the edge at 150x. I removed all of that and then moved on to the 8k side. I thought it was pretty good by running across my thumb. I even took a couple of shaves with it. Was not as smooth as I expected and with my lack of experience I also was wacking my chin.

What led me to look for advice is that most of what I read listed the hanging hair test as a standard test. In no way was the razor capable of meeting that test. That is when I started taking image captures on the microscope and looking for improvement. I did not see the improvement from the 1k to the 8k that I was expecting. If I had taken an image with light from above you could see that the rough cut from the 1k stone was gone but the 8k did not really seem to even up the actual leading edge much. Once it was pointed out that the gap from 1k to 8k was too extreme it made sense to me. I have ordered a 4k stone and if I am lucky it may be here by Saturday.

I also think the advice to get a properly honed blade makes a lot of sense; however, I want to push on and try to see what I can do with the 4k stone when it gets here. I am pretty determined when I set my mind to something and think I should be able to get a good edge. I will obviously know if that is true or not once I get the 4k stone in my hands and a day or so to play with it. I think messing around with the razor and the hones is good fun and think I can see my way through it.

I am also looking to pick up another used razor from Ebay since I have read that it is recommended that one have two razors ready to use. I am also expecting my strop to hit any day now.

In response to an earlier concern about affecting the temper on the blade I am sure that did not happen - the blade was pretty gray and dark when I got it. I used some steel wool to do initial cleaning and then disinfected with Hydrox Hydrocide. I then used a 6" buffing wheel on my drill press at 780 rpm. I am sure that I did not generate enough heat to impact the temper.

I would estimate that I probably put at least 80 round trip strokes on the 1000k stone. There were quite a few irregularities in the blade that I needed to polish through. I probably ran about 60 strokes on the 8k but as I said it did not really even up the leading edge but it did remove the scratches across the surfaces of both sides.

Thanks for all of the good advice. I think I am going to "pretend" shave with my razor during free time before my hone arrives so that I can get a feel for shaving with my left hand. I have not done that before but I find the contortions required to shave both sides of my face with my right hand really complex.

EdLast edited by eddelgado; 08-04-2010 at 02:46 AM.

-

08-05-2010, 12:40 AM #6Member

- Join Date

- Aug 2010

- Posts

- 34

Thanked: 4

Guys I attempted another round of sharpening today. Same stone the 1000kx8000 Norton. I don't expect to receive the 4000 stone until Saturday at the earliest. I tried using a less pressure on the blade and also doing the X pattern. I initially was using more pressure and going straight across the hone holding the blade off perpendicular.

It feels pretty sharp to me. After running it over the 1k hone side in about three sets of 10 passes it was cutting arm hair pretty nicely. I then ran bout 5 sets of about 10 passes on the 8k side. It feels pretty good to me and tested on leg hair it felt pretty smooth. I also received my strop today.

I am contemplating another test shave tomorrow - maybe avoiding the chin until I get more practice. Most of the nicks have healed pretty well.

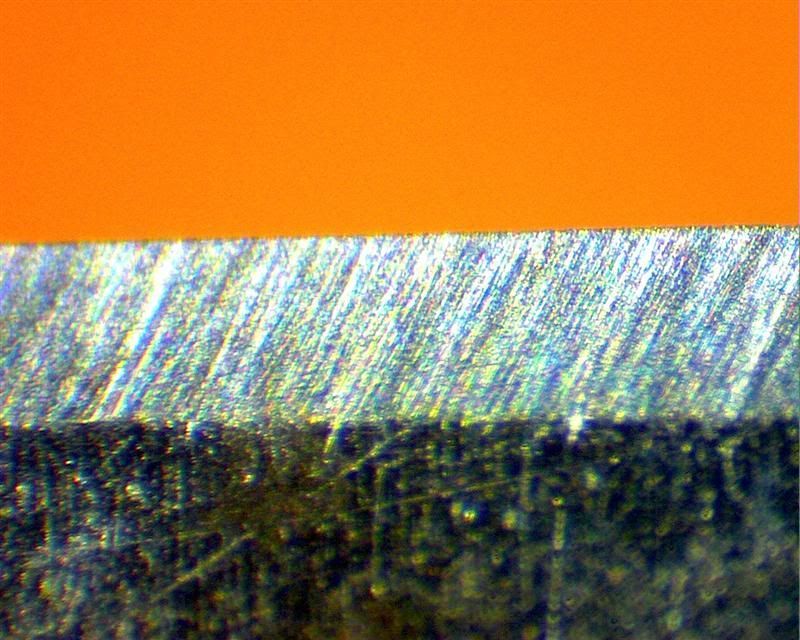

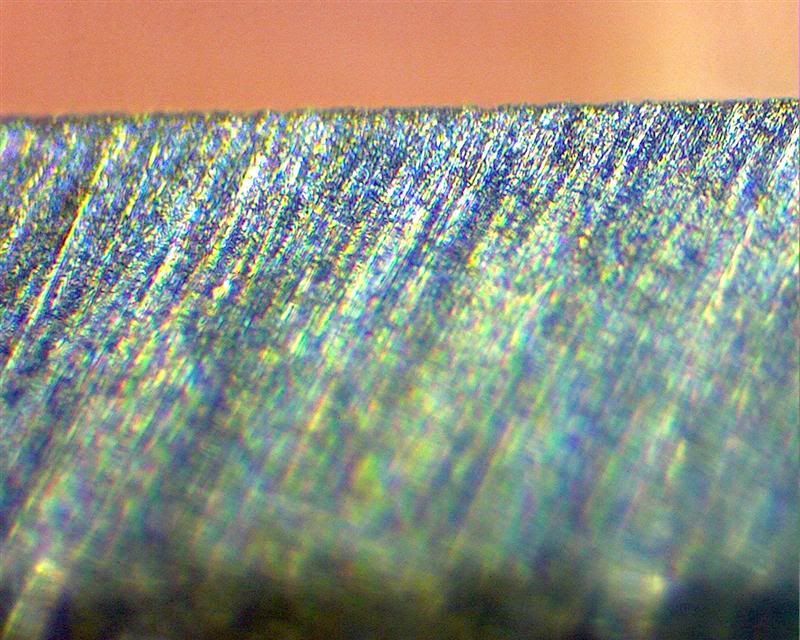

I am attaching photos from todays session using a light from above as well as from below.

Let me know what you think.

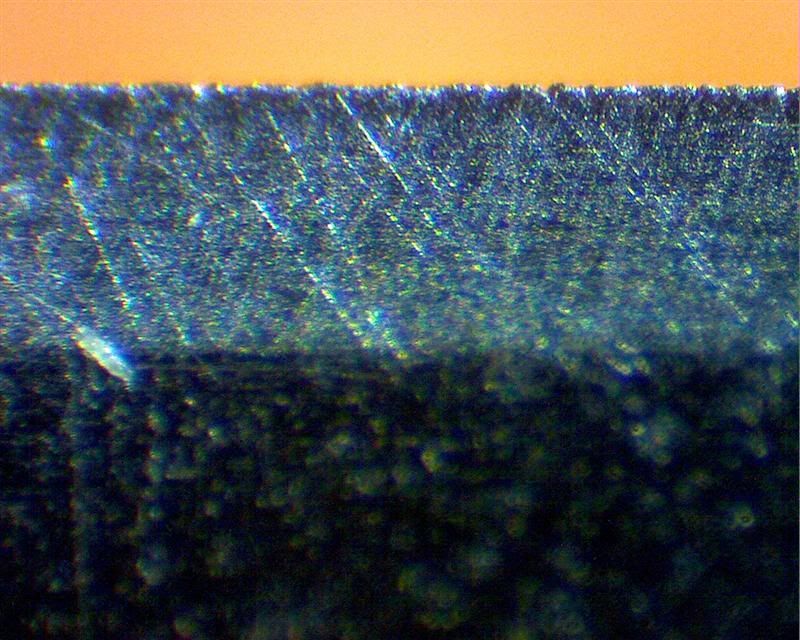

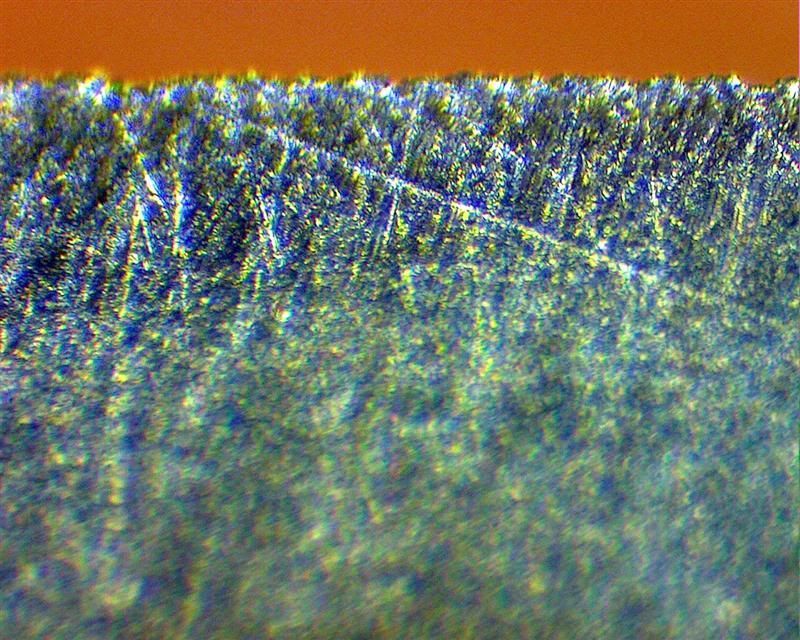

These images are after the 1000 grit side.

60x

150x

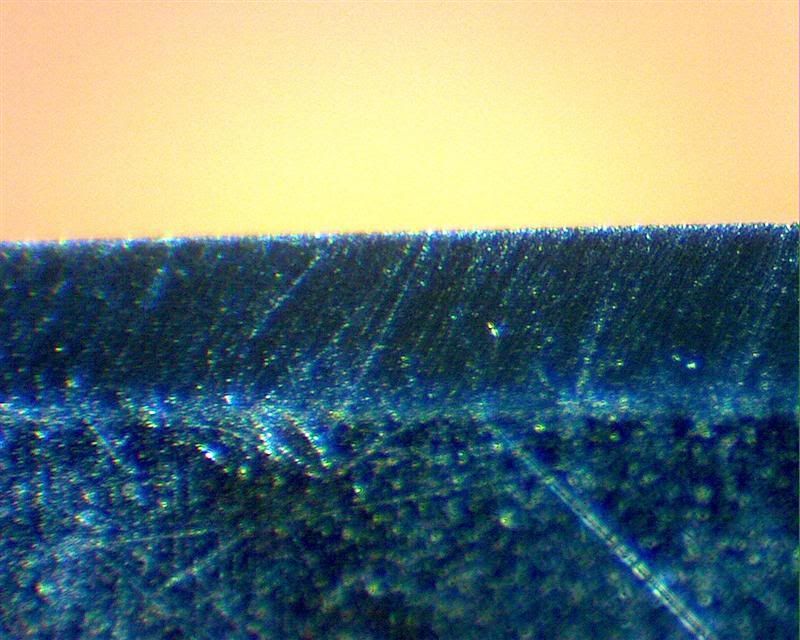

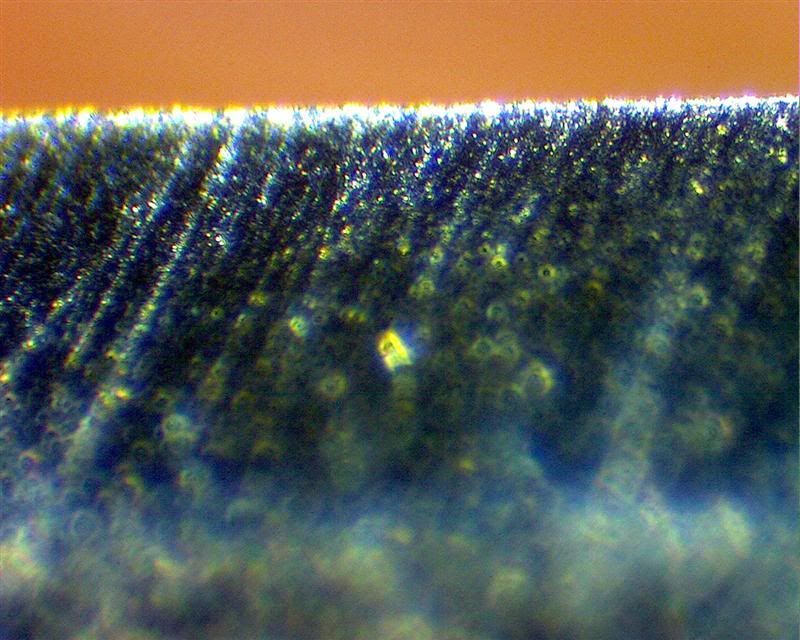

This is after the 8000 grit side.

60x

150x

This is after the 8000 grit with lighting from above as well as below.

60x

150x

Let me know what you think.

I have also started watching the classifieds here on this site to see if I can get my hands on an inexpensive structurally sound razor as well.

Thanks

Ed

-

08-05-2010, 03:28 AM #7

you have to stay on 8k a little longer.

your edge is half way in there on 8k.

try take all pressure off and make 10-20 strokes check the edge.

This is the best sign when you done 8k.

when you try to shave your arm hair hair will fall next to the blade silently.(no jumping etc)

if you get this then you have done on 8k,

above skin level.

gl

-

08-05-2010, 03:58 AM #8

I agree with Sham, a little more on the 8k and you will be right on target. Great pics, thank you.

It is easier to fool people than to convince them they have been fooled. Twain

-

08-04-2010, 01:49 AM #9

What I meant by correcting the chips is to hone them out with 1k. that edge as pictured is not ready for 4k

-

08-04-2010, 02:26 AM #10

I cant see the bevel because the image is too dark, but the edge looks like it still has a ways to go, its a bit of a jump from 1k to 8k, but it can be done. its just more labor intensive and time consuming. The HHT is unimportant IMO, and using the thumbnail is to determine if there are chips and nicks in the blade before honing, after the bevel is set the thumbnail should not be used or you will dull the edge destroying your work. While you are at woodcraft for a 4k you might as well pick up something in the 12-16k range as a finisher.

It is easier to fool people than to convince them they have been fooled. Twain

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote