Results 201 to 210 of 266

Thread: The C-Nat-athon

-

03-11-2012, 04:41 AM #201

Mack, I'd love to post up pics of my collection for you to peruse...

Here is just the razors and stones, not the shave den, or the strops, etc..

I tried to keep it brief, I don't want to hijack the thread!!

I did search for a place to put it, then I was just going to link to it, but WTH, I'll throw it in here just for you!!

M

6/8 Ontario, 5/8 Eagle, 5/8 Bockla, 5/8 Boker, 6/8 W&B 'Dogbone', 6/8 Genco Henry's XX, 4/8 Blasberg Kerry-Gow, 7/8 Puma

From bottom left in a zigzag up and down, 4/8 Challenge Razorworks, 6/8 Challenge, 5/8 challenge, 4/8 Fredrick Reynolds, 11/16 W&B, 5/8 Hub, 5/8 Blue Steel, 5/8 Silver Steel, 5/8 Wester, 6/8 Clauss, 6/8 Hamburg, 4/8 Friodur

8/8 Westonton, 4/8 Robeson, 3/8 Wostenholm, 7/8 Sibbal, 8 ea. 9/16 Spikes

Same, just a good shot of the 7 day set of spikes, the green one isn't part, but it's a spike just the same

Fromt the top 5/8 Shapleigh, 5/8 EBRO (both waiting scales), 7/8 Robeson, 9/16 Salamandar, 4/8 Genco Barbers

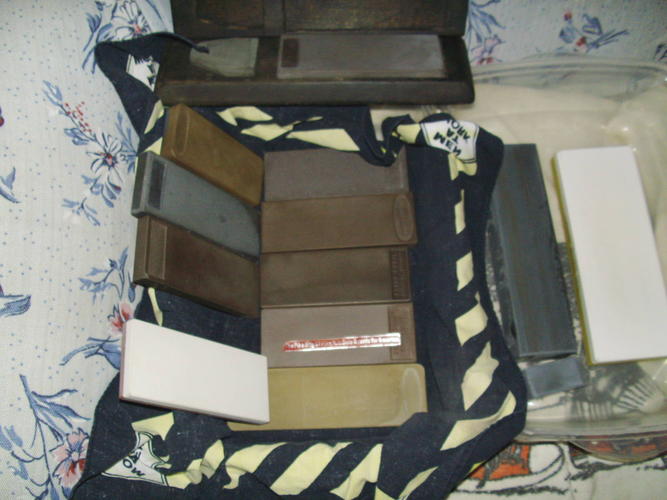

My box of 10 barbers hones, I won't list them all, but needless to say they are all collectible and special to me, I had over 30, but sold off the rest and kept (mostly) the best. Nicknbleeding got the other good ones!

My Cnat, Norton 4/8, King 800, King 1k

And last but not least, my DMT and Holder, my diamond paddle and CrOx paddle

Drat, I just discovered I missed 2 razors as well, my Mandarin and my G&F Timor. Oh well....

Enjoy bro!! If we need to we can move this to another thread somewhere, whatever..

MikeLast edited by mjhammer; 03-11-2012 at 05:16 AM.

-- Any day I get out of bed, and the first thing out of my mouth is not a groan, that's going to be a good day --

-

-

03-11-2012, 04:47 AM #202

Wow, you have an impressive and admirable razor collection Mike. Truly amazing, love how you got everything organized. You don't need to move it to another thread, I'm sure everyone loves eye candy the same as I.

-

The Following User Says Thank You to xMackx For This Useful Post:

mjhammer (03-11-2012)

-

03-11-2012, 02:41 PM #203

I'm impressed. You need a display case. They are all very nice.

-

The Following User Says Thank You to Crotalus For This Useful Post:

mjhammer (03-11-2012)

-

03-11-2012, 10:45 PM #204

Epic Failure today!!

I have a Franz + Sibald 7/8 with a pretty wicked curve, as in, it's close to 6/8 at the heel and a full 7/8 at the toe.

I tried doing a rolling X on it today. I did manage to get a bevel set, and it appeared to be pretty consistent across the blade.

BUT.... as I progressed to the 4k things didn't work out too well. As I tried to hone it using the rolling X's it seemed to get progressively worse, as some spots on the blade stopped cutting hair. The heel, which was my biggest worry, was about the best spot on it, but smack in the middle, it stopped cutting. The toe seemed 'ok', but not improved.

I tried for a good 2 hours to get it back, but never did.

I put her up again, but first, I removed it from the scales it was in as they were slightly warped and always harbored the chance of gouging as you closed the blade if you weren't super careful and guided it gently into place.

I had to throw her into the 'someday' pile and just because I went thru the trouble to get everything out and ready, I decided to see if I couldn't improve the edge on another razor, just so I could have some kind of success today.

I grabbed my little 4/8 Robeson 'Sure-Edge' and worked up a great slurry on the CNat.

I checked her capabilities before I started and she was darn sharp, popped hair easily, but still appeared a little bit harsh to me. So I worked it for about another 100 laps on the slurry and viewed the edge under mag. It was slowly becoming mirrored!!! I have yet to really see any edge go mirror on me, so I got really encouraged. I made sure to keep the same slurry working, not letting it run off the stone or the razor and managed a good 100 laps using the same slurry. Like Mack said, it seemed to get finer and finer as I went. After the last set of 25 laps I examined it again and to my surprise, I could barely make out any scratching pattern at all. There was the random deep scratch that stood out in the shiny parts, but other than that, it appears to have reduced any scratch pattern to invisibility under 30X.

I did my customary 5 laps on CrOx just to polish it a touch more and only did 25 on the clean felt and 100 on the leather (newly conditioned yesterday and a fresh side of felt to clean her on). I'm going to cook dinner for SWMBO and then I get my shower and shave for this fine Sunday.

I'm taking my 8/8 Westonton & Sons 'Again' razor in to the shave den with me as a comparison razor. That was honed up by my friend Rene (nicknbleeding) and has a fantastic, smooth edge on the monster wedge.

What a contrast, eh? going from a fresh nimble little 4/8 Robeson to a giant 8/8 (this blade is like 3 1/2" in length too!). This should be one cool shave!

Wish me luck!

M-- Any day I get out of bed, and the first thing out of my mouth is not a groan, that's going to be a good day --

-

03-11-2012, 10:58 PM #205

I honed up my new Russian today. When I got to the new Polish / C-nat I once again lost sharpness. It didn't pop hairs nearly as well as it did coming off the Norton 8K. So, I dropped back to the 8K. 100 strokes and the edge was back. 10 passes on .5 diamond on balsa, 200 on the strop. HHT wasn't the best, but the shave was great.

After the shave I did 50 more on the strop. Passes HHT-3. Go figure.

I'm going to enjoy the Russian. It's exactly the same dimensions as my King Cutter. I'm beginning to like that size.

I'll keep experimenting with the C-nat. Gotta be doing something wrong. I lapped it, soaked it, hmmm, I didn't chamfer it.Last edited by Crotalus; 03-11-2012 at 11:01 PM.

-

03-11-2012, 11:00 PM #206

Mike, when I was looking at your pics I was going to say you should try working the same slurry for a while because your c-nat looks somewhat similar to mine. I get the same results, finishing with just water I get a definite scratch pattern but finishing after working the slurry gives it that mirror finish like you describe. Still a scratch pattern but you got to twist it in the light to see it. Using it with slurry and without slurry is like a night and day difference.

I've been trying to work the same slurry and reuse it for a few days now. It's hard because I end up losing some every time because it slowly sticks to the blade, but I have been getting great edges off of it.

-

03-11-2012, 11:31 PM #207

I know exactly what you mean. I either push it off the end, or it stays on the blade and during the flip ends up on the shammy. This time I let it dry on the surface as best I could before putting them away in the hopes that when I re-wet the CNat some of the original slurry will still be there.

I kept trying to 'drain' the blade before the flip, back onto the stone to try and capture as much back as I could before losing what was on the blade. It slows down the honing process, making every 25 laps take even longer, but the result seems to show it is worth it.

I have gotten good results without any slurry, but the number of laps needed was double what the slurry seemed to give. I think you are spot on about my stone too. The longer you keep the slurry in play, the smoother the edge seems to get, with fewer strokes needed!!

I think I have honed at least 30 razors in the last month. And what's weird is I still need WAY more practice at it to even feel slightly competent. Some razors I just cannot get to take even a bevel, let alone make it to shave ready. HAH!!

Glad you started this one Mack, I've been following the 1k test, I did the JaNorton and I can honestly say, there is no way I'm shaving off a 1k bevel I've made. I really rely on the bevel off the 4k a lot more than the 1k. Between the 800 and the 1k I barely get a decent bevel, but by the time I'm done on the 4k, it's pretty darn good. Just more food for thought for me!....

Just about to get to dinner, than off to shave!

Lata!!

m-- Any day I get out of bed, and the first thing out of my mouth is not a groan, that's going to be a good day --

-

The Following User Says Thank You to mjhammer For This Useful Post:

xMackx (03-12-2012)

-

03-12-2012, 01:36 AM #208

Just got done honing my Perfecto razor on the reused slurry. Something I noticed, not only finishing on slurry gives me a much more refined edge, but also gives it a much smoother edge. I say this because good c-nats are notorious for giving about the keenest edge out of any stone, but when I finish on slurry it gives a nice keen and smooth ratio I tend to go for and prefer. Passes a the HHT 5, clean cut no sound, just falls over effortlessly.

Last edited by xMackx; 03-12-2012 at 01:40 AM.

-

03-12-2012, 02:07 AM #209

As a sign of HAD I bought another stone to compare with the one I had. A 2 X 8 inch at about half the price or I wouldn't have. They had 3 at Wood crafters and they all looked similar. Without an "official" test this one seems harder. I used a slurry stone from my other one so that might have influenced things.

i don't see a mirror finish coming off of these. More of a satin finish. go back to the 8K norton and there is a mirror finish with a few deeper scratches. Use the C-12k and the deeper scratches disappear but the whole thing has a satin finish. Go back to the 8 norton and the bevel is 99 percent mirror with a few scratches. Is the satin finish covering up the deeper scratches?

Tim

-

03-12-2012, 02:21 AM #210

That's a question I would only be able to answer by seeing it. When you say satin, I think... I know what you mean. On any stone when I have replaced the previous scratch pattern completely there is a sparkly look to the bevel. Something I will tell you that makes a big difference is how you create your slurry. When I use a lot of pressure to create slurry the particle size is bigger and it can scratch up the stone. Since you said this one is harder, try using my method of creating slurry I posted before. I bet you'll see a big difference, maybe. I'll just copy it here so you don't have to look for it through the pages.

How I raise a slurry to get the best edge:

I have had this stone for quite a while now and have tried about every way to raise a slurry and this method gives me a much better edge than others I have tried.

Since these are hard and slippery stones, the natural instinct is to use a lot of pressure to raise the slurry quicker but the more pressure you exert to raise the slurry the larger the particles will be and can scratch up your stone.

I take 6-1K sandpaper, in this instance I am using the 6K side of a nail file out of convenience. I score the slurry stone so that it has fine scratches all over the side that will meet the stone in use. I use light pressure (the lighter the finer the particles) and slowly polish those scored scratches off the slurry stone. You can also score the surface of the stone if you like a thick slurry or you can dry the slurry stone and re-score the surface. This is just what I do with my stone and thought it may help others and remember these are natural stones so yours may vary but this method gives me the best results. You can see in the picture that the scratches on the slurry stone have polished out, depending on how much slurry you want you can rescore and repeat the process until the desired thickness is achieved and it keeps the stones surface scratch free and polished. Oh and remember to wipe off the slurry stone after scoring it so there is no unwanted particles.

-

291Likes

291Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote