Results 1 to 10 of 22

Thread: How to hone a Japenese wedge?

Hybrid View

-

03-04-2012, 06:20 AM #1

Oh boy.

I've been trying to get this guy to grind out hollows for MONTHS. Maybe a year?

I've tried to hone at least a half dozen and not gotten a reasonable edge on a single one. If you do, let me know.

It's not the steel, it's not the heat treatment, I'm convinced it's the grind. He's grinding them at 23 degrees+, and then you have to hone with tape, and it just doesn't feel good on the face.

By the way, it's "Takami" not "Tensui." Takashi would read it that way, but that tells me he's not in direct contact with the maker...just an FYI.

-

-

03-04-2012, 02:53 PM #2

JimR, interesting that you know this razor (and the maker?). I looked all over the net, including your site, for experience on it; not finding any, knew I was taking a risk. Guess I should've asked you first!

I wouldn't know about the angle of the grind, but it sounds like I'm not the only one who's experienced the futility of honing the bevels flat on the hone, as the seller recommends. I'll let you know how it shaves...

Also thanks for the correction - I used "Tensui" because the seller's page refers to "the blacksmith, Tensui". Good to know his real name is Takami. But who is Takashi? (I was born in Tokyo and some of my first words were Japanese, but I don't remember any of it.)Last edited by denisb; 03-04-2012 at 02:57 PM.

-

03-12-2012, 04:02 AM #3

Denis,

Sorry i haven't replied yet.

Takashi (or is it Takeshi? Can't rememnber) is the guy in charge at Aframestokyo. It's not a language thing, he's using a very odd alternative reading for the kanji in the name he chose. Anyone who just saw the name would read it Tensui, but he says it's Takami.

That's probably the reason you couldn't find info on my blog, too.

I must say, I'm glad and surprised you could get an edge on it. I've given up, and the other readers of my blog appear to have as well.

-

04-17-2012, 05:48 PM #4

Final report: what worked for me

Final report: what worked for me

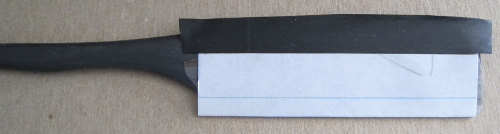

I can't leave this thread without sharing how I set my secondary bevel and got a decent shaving edge on the Takamitou wedge razor. The key for me was to change the conventional taping method, which doesn't work with this razor. The reason is the razor's irregular geometry.

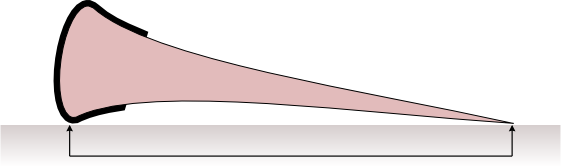

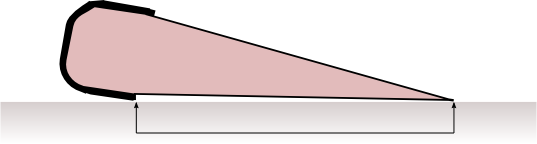

On a hollow ground razor the spine is machined to a consistent distance from the edge. Also, the fat part of the spine creates a consistent height and length for the angle of the secondary bevel. That makes it simple to tape: you don't have to center it exactly, as long as both sides extend into the hollow.

On the Takamitou wedge, you do have to be exact about taping, because the edge of the tape, which touches the hone, determines the height and length of the honing angle. What's more, the Takamitou's spine is not machined, and it's curved a bit from one end to the other. So if you wrap your tape around the spine in the usual way, it's unlikely to be the same distance from the edge of the blade at every point. As a result, the angle of your secondary bevel will be inconsistent, making it impossible to get a well-honed edge. I suspect this is why people haven't been able to sharpen this razor.

Enough theory, here's the method I used:

1. Cut a piece of electrical tape the length of the spine. (Note, I used a single piece of tape, not two, to keep the angle within recommended limits)

2. Cut the tape in half lengthwise. Note the "factory edge" of each piece (the edge you didn't cut), and put it some place where you can easily pick it up later.

3. To make the jig, cut a piece of heavy-gauge paper to the long dimension of the blade.

4. Fold the paper in half along the length, creating a sharp, straight crease. Using a straightedge, cut your jig to the width of the bevel.

5. Open the paper and carefully place the sharp edge of the blade into the crease. Hold the jig snugly against the edge and sides of the bevel, being careful not to cut the paper (or yourself!).

6. Tape the spine, one side at a time, using the jig as a guide. Be sure to apply the factory edge of the tape against the jig, not the edge you cut.

That did the trick for me. With this taping, my honing was pretty standard: after a Norton 4k/8k pyramid sequence, I finished on my Chinese waterstone and a few strokes on the CR 0.5 balsa strop.

I'm getting good shaves with this razor. Before each shave (after the first one) I give it 30 or so strokes on the leather strop, with a little slack since this is a wedge. I've kept the paper jig so I can use it the next time the blade needs honing.Last edited by denisb; 04-17-2012 at 05:59 PM.

-

04-17-2012, 08:54 PM #5

What's the purpose of the piece of paper?

-

04-17-2012, 09:33 PM #6

I had no problem getting to the edge on the one I honed, the razor holding its edge was another matter.

-

04-17-2012, 09:46 PM #7

Why not use a metal cuff that can be shoved over the spine of the razor instead of tape? Would that be something to use on this razor?

Mastro Livi once made one for majurey. It is described in 3rd post of this thread and commented on in a few posts following it. http://straightrazorpalace.com/gener...tml#post135447

Unfortunately the pics are no longer available.Last edited by Kees; 04-17-2012 at 10:01 PM.

-

04-18-2012, 01:09 AM #8

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote