Results 21 to 29 of 29

-

09-25-2012, 07:07 AM #21

I love to admit that I am wrong - again. The king stone was not faulty - my technique is. One day you think that the problem is one thing and the next day something else as you can see from this thread. I have kept notes to help me nail down what is working.

1. For bevel setting the king stone was an issue. It is too slow for my technique. I had much better success with the chosera or the dmt plate.

2. My circles suck big time! For some reason I do the circles in a wobbly manner which creates a more obtuse bevel. And so I will never get there doing circles.

3. Once I am close, I did way too many strokes. Somehow this always dulls my edge. My consistency isn't at the level which allows many laps.

4. Swooping/rolling strokes require a lighter relative pressure since the edge contact area is smaller.

5. Occasional backstrokes help to clear burr/debree from the edge.

6. I used too light pressure with uneven strokes at the end. Normal light strokes work better.

7. At some point I was torquing the egde in or lifting the spine ever so slightly before flipping the razor. I was careless.

Last night I was able to complete 3 bevel sets where they cut arm hair easily and are grabby with the tpt. Yay! Knife sharpening is for pussies if you ask me.

-

09-25-2012, 09:54 AM #22

Now that I have had some success I have few things on my mind.

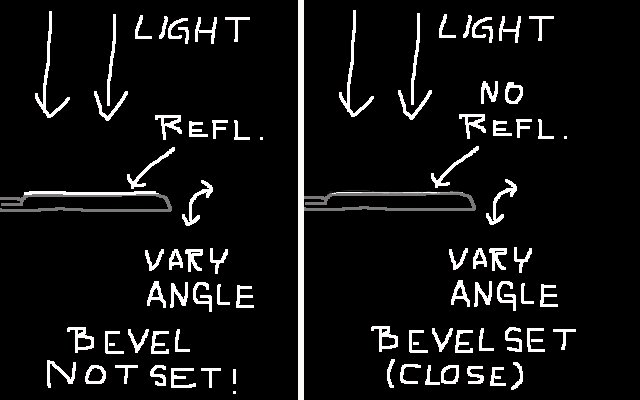

Glen (gssixgun) and I think Lynn too can both feel or see on the bevel setting hone when they are coming close and thus know when they should lighten up on their strokes. I find feeling the edge on the hone to be very difficult. So if they or somebody else could assess what they are looking for when the edge is getting close. I found that undercutting the water was not very reliable sign, at least in my case. Also looking at the bevel (edge?) under the light, what exactly should I look for? And at what angle? Microscope is easy, if you see a white line or edge - you are not there yet. When there is no white line or other reflections you are getting close. But it would be much faster to assess on the hone or against a bare light.

-

09-25-2012, 12:35 PM #23

When you look directly down on the edge with a 10X loupe, razor held vertically toward you, under bright light, if you can see the edge at all the bevel is not yet set. A completed bevel leaves an invisible edge.

-

The Following User Says Thank You to ace For This Useful Post:

MikkoK (09-25-2012)

-

09-25-2012, 02:44 PM #24

I did some bevel setting experiments on my kitchen knife and chosera 1k.

I have not - until now - realized how little it takes to set the bevel or kill it. First you bring it close with some heavy honing and once everything is in place, you just clear the burr/debris and do few no pressure strokes and BAM! the bevel is set. My kitchen knife is now passing all bevel set tests .

.

Now this is the part that is still a mystery to me. While doing the bevel setting, I went over few times and had to take couple steps back because the edge seemed to go dull. What is it that happens at this point? Does the steel at the very edge get somehow fatigued and break away?

No biggie, a tnt clears it up nicely and few ultra light strokes and the bevel is set again. I think this was a good practice. Of course razor is not exactly the same since you can't play with honing angles and I guess it takes a little while longer to bring the edge back in once you go over.

Ace - thanks for the tip. This test seems quite reliable and shows if you are close. I just used a bright led lamp, no loupe needed. It helps to have something with dark background to see the reflection off the edge. In fact, I think this is the thing that Glen mentioned in his videos, but said he did not know how to show it. Man I wish I had understood this earlier.

I think there should be a diagram that looks something like this in the wiki. The edge is facing the viewer and you have to seek the correct angle, but once you find it, it is very clear if there is a reflection.

Last edited by MikkoK; 09-25-2012 at 04:15 PM.

-

09-25-2012, 02:54 PM #25

-

09-25-2012, 03:10 PM #26

^^ There you go. I made one, because I think it is such a fundamental piece of information that can be used in bevel setting.

-

09-26-2012, 03:02 PM #27

I completed the honing of the frameback. I had interesting things happening again. I set the bevel with 1k as well as I could and changed the tape after that. I did about 10 strokes on the 3k and it got duller again. It did not cut hair or pass tpt. I was on this stone for good 45 mins before I was happy with the edge. I did back strokes occasionally to clear any burr or debree on the edge. Then about 30 laps on the 8k and 20 laps on the 12k. I finished 5 laps on 1um diamond and 5 laps on 0.5um cox. Then about 50 laps on the strop.

I had one of the nicest shaves of my life. The smiling edge really helped to get the jawline shaved well. I had no cuts or irritation afterwards. After the shave I checked the edge with a 60x scope and there was still a small white line visible. I guess my bevel set at 3k was still not perfect. That edge deterioration thing at 3k still bothers me. I hope I will understand why it happens some day.

-

09-26-2012, 03:42 PM #28

It is just fine to skip from a 600 grit to a 4k grit and skip the 1K and see if it works for you.

The grit jumps from different vendors can prove difficult to untangle.

So try setting the King to the side and see what happens.

It may not be faulty it just may not be needed.

One quote from above is worth repeating.

Let the hone do the work....

A light touch takes a bit of practice.....

-

09-26-2012, 05:52 PM #29

I got the 1k chosera, which I already love, to replace the king. It is much faster and allows me to use less strokes to set the bevel. The king was not faulty, but I did not know how to manage the bevel set with it. And I getting close, but was using too much pressure at the end. Thus, I always had some kind of burr that did not get thin enough to pass the tests.

Last edited by MikkoK; 09-26-2012 at 06:01 PM.

7Likes

7Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote