Results 21 to 30 of 50

Thread: Solving a Mystery

-

05-01-2013, 02:22 AM #21"My words are of iron..."

- Join Date

- Oct 2006

- Posts

- 1,898

Thanked: 995

Not every inch of a bar of steel must be good. There are a good many reasons that could occur during several points in processing. Inclusions are not uncommon. It's a risk anyone grinding on a perfectly good bar can find. It's a little more risky on pattern welded stuff but then we are sticking materials together in a way that can cause anything from big to small inclusions. It could be decarburization at the edge during the heat treatment cycle (done badly), or an edge is built from what looked like good steel but was decarb on the billet during forging. Rusty oxide pitting, sure that too. Poor quality control, the final inspector just got fired and took his revenge.

Here we are doing a forensic evaluation...RSI in action.

-

05-01-2013, 03:58 AM #22This is not my actual head.

- Join Date

- Nov 2009

- Location

- Middle of nowhere, Minnesota

- Posts

- 4,624

- Blog Entries

- 2

Thanked: 1371

RSI in action...

Last edited by HNSB; 05-01-2013 at 04:05 AM.

Strange women lying in ponds distributing swords is no basis for a system of government.

-

05-01-2013, 05:09 AM #23This is not my actual head.

- Join Date

- Nov 2009

- Location

- Middle of nowhere, Minnesota

- Posts

- 4,624

- Blog Entries

- 2

Thanked: 1371

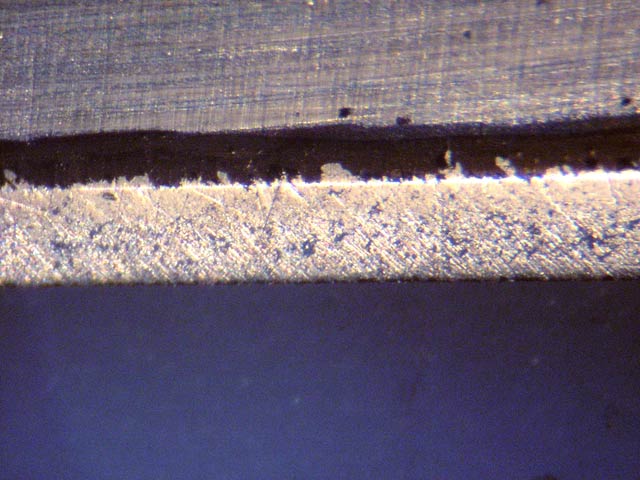

Another piece of the puzzle, and things are starting to make a little more sense:

I was curious about the small burr at the edge; I wanted to see if I could get a better idea about what's going on there, so I markered the bevel and did one stroke on a 12k:

Notes:

The lighting in this picture isn't the same as the other - when I took that one I had daylight filtering in through the windows.

For anyone that's just learning to hone and following along: this step wasn't necessary. If I was just honing it, I would have gone to a bevel setter and started working. This step and picture was entirely because I am curious about what's happening at the edge.

Regarding magnification:

In the area that's photographed, the bevel is .024" wide. It is photographed essentially flat (perpendicular) to the lens of the microscope. After resizing the image to 640x480 for web viewing, for my monitor / resolution, the picture on the screen is approx. 60x actual size. (unless I made an error in my math)

Doing this calculation makes me wonder about how magnification of microscopes is determined, especially the USB scopes... Based on the manufacturer's claims of magnification for USB scopes I've used in the past, I would've thought these pictures to be well over 100x.Last edited by HNSB; 05-01-2013 at 05:24 AM.

Strange women lying in ponds distributing swords is no basis for a system of government.

-

05-01-2013, 05:56 AM #24

Is that marker at the very edge?

-

05-01-2013, 07:13 AM #25This is not my actual head.

- Join Date

- Nov 2009

- Location

- Middle of nowhere, Minnesota

- Posts

- 4,624

- Blog Entries

- 2

Thanked: 1371

-

05-01-2013, 03:45 PM #26Senior Member

- Join Date

- Mar 2012

- Posts

- 273

Thanked: 43

To me the metal in the photo appears very old and pitted and the bevel looks old too because of the rough surface.

I suspect that rusting of the metal over a long period of time has had a negative effect on the quality of the metal. I don't mean the obvious pits but some of the metal that still looks good has been compromised as well.

I don't know what happens but maybe some iron content is leached away from the metal surrounding the pits?

Do you suppose he finished up using a circular and/or a back stroke on a hone that had a lot of loose grit and metal particles on it?

Also it looks like the bevel was not properly set so the rounded edge would be cutting through the "mud" rather than lifting it up and over the bevel.

I know a lot of people have good luck with using a slurry but for some managing it can be problematic.

The blade in question has suffered from multiple problems. The only solution is to reset the bevel further up the blade and hope for better metal there.

A few strokes on a hone should tell you a lot.

If you can reach good metal and use a good honing technique the razor should be fine.

Maybe you could post a photo of the bevel in progress and when finished?

-

05-01-2013, 06:37 PM #27This is not my actual head.

- Join Date

- Nov 2009

- Location

- Middle of nowhere, Minnesota

- Posts

- 4,624

- Blog Entries

- 2

Thanked: 1371

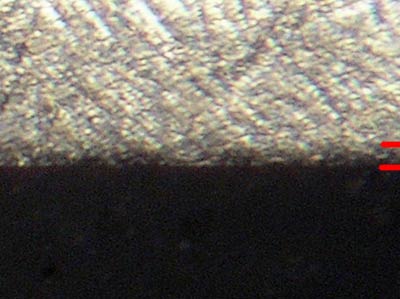

I stropped it and took this picture.

The magnification on this one is about 180x:

The red lines indicate the microbevel. Everything above that in the image is part of the bevel.

I took this one to see if I could get an idea about the convergence of the bevels. It's hard to see in the picture, but was pretty obvious under the microscope that there is steel all the way across that microbevel.

I'm pretty convinced now that the weak steel there has been just flexing and chipping at the whim of whatever pushes against it.

Now, that's enough messing around... Time to actually hone it and see what happens.

Last edited by HNSB; 05-01-2013 at 06:39 PM.

Strange women lying in ponds distributing swords is no basis for a system of government.

-

05-01-2013, 06:39 PM #28Senior Member

- Join Date

- Apr 2012

- Location

- Diamond Bar, CA

- Posts

- 6,553

Thanked: 3215

Looks very similar to Double Ducks I have seen, that have been sitting in deteriorating, off gassing celluloid scales and may have been last honed with a taped spine so the edge is still not making contact.

Breadknife to good edge steel, pitting does seem extensive.

A Great example of the benefit of the marker usage, by the way

-

05-01-2013, 08:14 PM #29This is not my actual head.

- Join Date

- Nov 2009

- Location

- Middle of nowhere, Minnesota

- Posts

- 4,624

- Blog Entries

- 2

Thanked: 1371

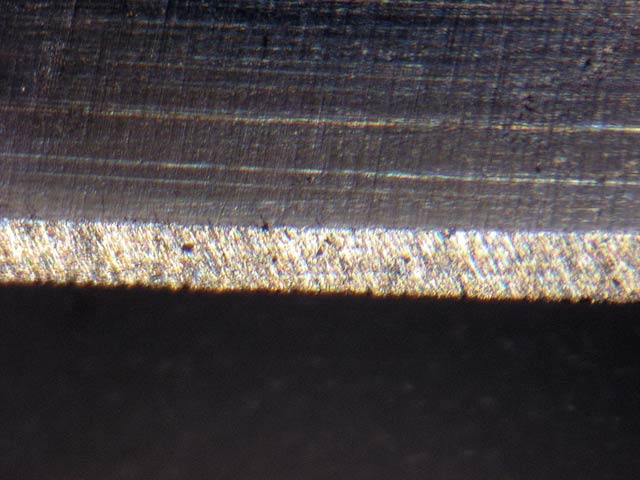

Here's what it looks like after 30 laps on a Chosera 600:

Strange women lying in ponds distributing swords is no basis for a system of government.

-

05-01-2013, 08:40 PM #30'tis but a scratch!

- Join Date

- Oct 2010

- Location

- Durango, Colorado

- Posts

- 2,080

- Blog Entries

- 2

Thanked: 443

Looks like it'd pass the hanging porcupine quill test, if you got a good swinging start. And like the (Yarrrr!) devil's spit has tunneled into the steel a bit.

Last edited by roughkype; 05-01-2013 at 11:31 PM.

"These aren't the droids you're looking for." "These aren't the droids we're looking for." "He can go about his business." "You can go about your business."

70Likes

70Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote