Results 1 to 10 of 27

Thread: Kamisuri question

-

06-06-2013, 11:33 AM #1

Kamisuri question

Kamisuri question

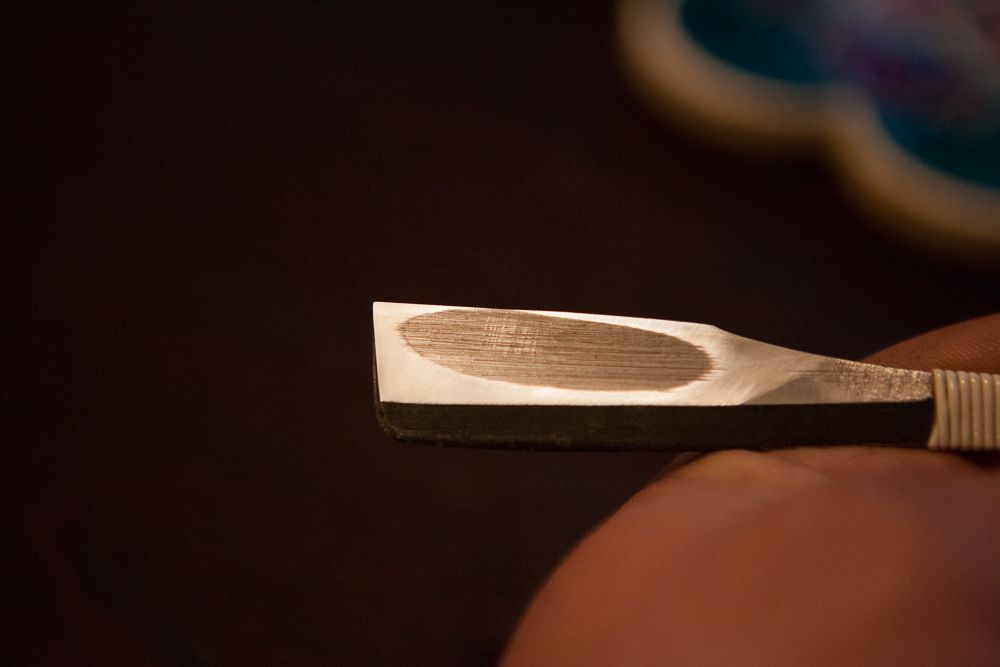

Ok guys i have just got my first Kamisuri ,it had never been honed but i have started to hone it with a bbw because i didnt want to go to coarse on it.So the bbw is working but its taking a long time its nearly there but not quite ,would a 1000 or 2000 grit synthetic be ok to speed things up a bit and get the bevel set or should i just be patient and keep on with the bbw.Here are some picks of where i am up to any advice would be great thanks,there is a little spot on the front of the blade and the heal of the front of the blade does not even look like its being hit by the hone.

-

06-06-2013, 12:31 PM #2

These videos by gssixgun should help!!

Regards,

Howard

gssixgun Kamisori part 1.wmv - YouTube

gssixgun Kamisori part 2 - YouTube

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote