Results 1 to 10 of 13

Thread: Tripple bevel

-

06-21-2013, 10:57 AM #1Senior Member

- Join Date

- May 2013

- Location

- Berlin, Germany

- Posts

- 286

Thanked: 39 Tripple bevel

Tripple bevel

This is an interesting experiment and a visual demonstration for the non-believers.

Every now and then someone is honing a razor with a 5k or even higher grit stone and wondering why the thing is not getting sharp. He then will be told that the most likely the bevel has not been set properly and that it is almost to impossible to accomplish that with a high grit stone.

Yesterday I had a look at the edge of my Friedrich Schrick, that I recently got from ebay. The edge was dull but undamaged and I found that it had a "nice" double bevel on one side.

The very edge had been honed with a greater angle. Very nice to see under the loupe and when watching the reflections. When turning the blade under light, the reflection "switches".

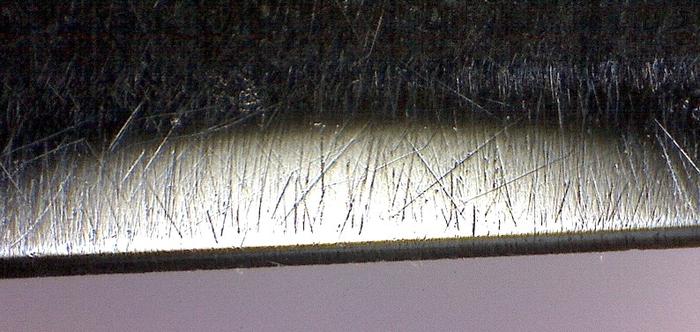

Under the microscope it looks like that:

There are hone-marks on the spine. So it had been honed without taping, at least some time in history. I use tape, especially here, as I need a steeper angle to get down to the very edge. If the last honing had been done without tape, the old (upper) edge would be less steep than my new scratches.

And so it was. In order to see where I was, I taped the spine, did some 20, 30 strokes on a 5k stone and got the expected result:

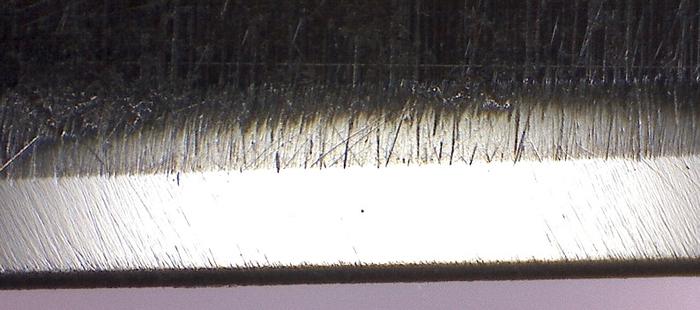

From bottom up: the very steep edge, followed by my taped strokes and the not taped strokes. We've now got three bevels.

As we're cutting with the edge, this is our primary target. However, I can't get there, as my bevel is in the way. The third bevel is of no interest, as it is less steep and I am already able to overcome it with my 5k strokes.

Seeing how much I achieved with just a few strokes on a 5k stone might lead to the conclusion, that the tiny rest could be done easily as well. We're talking about something like 220 power and the width of the lower bevel is around 0.04mm (0.00 inches shown ). Should be an easy job, shouldn't it? The answer is NO!

). Should be an easy job, shouldn't it? The answer is NO!

Going down to the bevel setter is the only way, but as I had this nice demo-situation at hand and felt like playing, I first did something like a 100 strokes on the 5k and some circles. The effect was close to nothing.

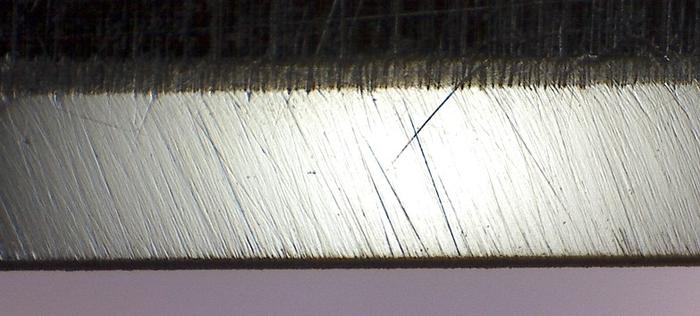

I then went down to a 3k stone and did about 200 circles and several hundred x-strokes. The outcome after about an hour of work was this:

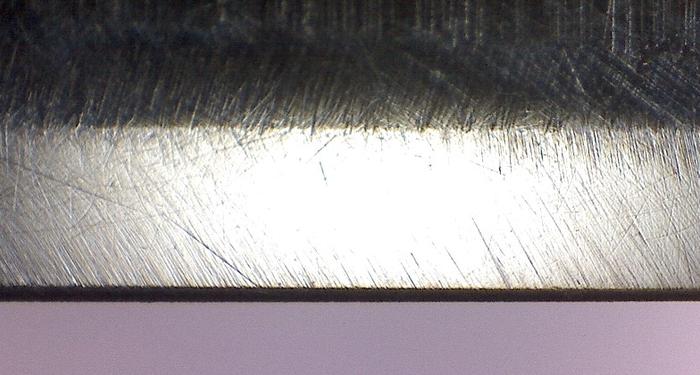

As You see, the new bevel is mainly crawling up towards the upper (and less steep) bevel and close to nothing down to the edge. After more than an hour of honing on the 3k stone, I did not touch the edge once.

The lower bevel now is a bit smaller, but still there. It can hardly be seen with a loupe. Reflection still works to detect it, but You need to know what You're looking for.

It would now probably take another 1000 x-strokes or more to get down to the edge. Until that is not reached, the razor's sharpness is not affected at all.

In this case the razor already had the second bevel. However, the effect is the same when You get a razor honed with unknown ( but steeper ) angle.Last edited by DDTech; 06-21-2013 at 11:00 AM.

-

The Following 3 Users Say Thank You to DDTech For This Useful Post:

Geezer (06-22-2013), Mvcrash (06-21-2013), Rockabillyhelge (06-21-2013)

-

06-21-2013, 11:27 AM #2< Banned User >

- Join Date

- Dec 2012

- Location

- Long Island NY

- Posts

- 1,378

Thanked: 177

Thats why I use dmt 325 600 for pre bevels on blades like this. Then the dmt 1200 or the norton 1k. You will probably get microchips on the low grits but I dull on glass and do a couple sets of 50 circles, 50 laps 50 x strokes to get the chips out and a good edge on with the 4k. When I say a couple, I mean 2 or 3 or 4 or 5. When its ready, its ready. Test cut arm hair, until it does, stay on the 4k. Then up from there.

-

06-21-2013, 01:16 PM #3

Guess I'm gonna have to give that Genco of mine another go.....

-

06-21-2013, 03:54 PM #4Senior Member

- Join Date

- Apr 2008

- Location

- Essex, UK

- Posts

- 3,816

Thanked: 3164

If I didn't have quick bevel-setters (DMT 600, chosera 1k) then I think I would have added another layer of tape and worked on the edge, rather than the shoulder of the old bevel.

Regards,

Neil

-

06-21-2013, 04:10 PM #5At this point in time...

- Join Date

- Jun 2007

- Location

- North Idaho Redoubt

- Posts

- 27,032

- Blog Entries

- 1

Thanked: 13246

Seems to me that you just learned why the razor had the double bevel in the first place

somebody didn't want to take the time, or perhaps waste the steel to re-set to the old bevel, what does the spine look like ????

somebody didn't want to take the time, or perhaps waste the steel to re-set to the old bevel, what does the spine look like ????

-

06-21-2013, 05:31 PM #6

Interesting, please post the photo of the bevel set and what grit stone you used.

“Two things are infinite: the universe and human stupidity; and I'm not sure about the universe.”

Albert Einstein

-

06-21-2013, 07:51 PM #7

-

06-21-2013, 11:11 PM #8

I think a lot of people have multiple bevels on their razors, a condition which they didn't want or even realize they had.

Just bad honing.No matter how many men you kill you can't kill your successor-Emperor Nero

-

06-22-2013, 12:31 AM #9

A razor with a warped spine will have a bevel like that if one tries to hone it flat on a wide stone.

The white gleam of swords, not the black ink of books, clears doubts and uncertainties and bleak outlooks.

-

06-25-2013, 11:48 AM #10Senior Member

- Join Date

- May 2013

- Location

- Berlin, Germany

- Posts

- 286

Thanked: 39

6Likes

6Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote