Results 801 to 810 of 927

Thread: The Stub-Tailed Shavers

-

05-26-2019, 01:58 PM #801

I've been curious about how the inlays were made and "implanted" into the horn.

The edges of horn where it meets the inlay (on many that I have seen) look melted, making me think the horn was heated to allow a more close fit.

I think the melting point of tin must be to high to pour it into the horn...

BUT the metal bars Tom recently received, Cerrosafe, melts at 190F or so.

... Hmmm... Maybe Cerrosafe could be poured in..?

Or heat horn and Tin up and then press it into the "imperfect" carved recession to make up for the imperfection?

Any threads dedicated to inlay processes? I do remember that old-school device used to make inlay recessions, but any other rediscovered processes?“You must unlearn what you have learned.”

– Yoda

-

05-30-2019, 01:58 PM #802

-

The Following 2 Users Say Thank You to lohar For This Useful Post:

Geezer (05-30-2019), Voidmonster (06-01-2019)

-

06-01-2019, 04:36 PM #803

There are a variety of different alloys that fall under the pewter umbrella. Presumably, reaction times vary with the alloys.

Also, since the alpha allotrope is physically larger than the sturdy beta allotrope, it looks like pressure can prevent the conversion from happening. The chemistry of it is well beyond me, but I've seen one paper (thanks, ScienceGuy!) that suggests even the squeeze caused by being pinned between scales would be enough to stop it. Basically, enough that there's no room for the swelling of alpha allotrope seed crystals. And, anecdotally, I have seen a lot of old razors where the outer perimeter of the wedge is crusty and everything that was inside the scales is still bright.

After some more digging around, I've only muddied the waters.

Since the 16th century, there were three types of pewter made in England. Fine metal, trifle, and ley metal.

Fine pewter was tin with about 1% copper and nothing else. Today that's called Britannia metal.

Trifle fine pewter with 4% lead added.

Ley or lay metal was tin with 15% lead.

My assumption here has been that they would've used the cheapest option for these, but I'm probably being wrong-headed about this. The industry was deeply entrenched in traditionalism, and there may have been some reason lost to history that they used plain old tin. The more I think about it, the more I think the workers wouldn't have called the wedges 'tins' if they were pewter, since pewter was a regulated term -- even ley metal.

Clearly, some day I should take a bunch of samples and get them tested.-Zak Jarvis. Writer. Artist. Bon vivant.

-

-

06-01-2019, 04:44 PM #804

I don't know for a fact how it was done, but there are a variety of options.

The simplest would be to have the recessed parts built into the scale mold. It's often forgotten, but the old scales were all pressed horn, most were just very simple. A worker could then pretty quickly use a graver or some sort of cutting tool to make undercuts on the edges. A roughly shaped piece of metal could be put in, peened with a hammer, then imprinted with a pattern die.

Another possibility is an ingenious old Sheffield tool: the two legged passer (or parser) drill. Check it out!

Either way I suspect that getting the metal into the scales was some variation of 'rough metal in, peen, imprint'.

Of course, some inlays also had holes all the way through the scales for anchoring, but those were usually larger ones, and often made of nickel silver or actual silver.-Zak Jarvis. Writer. Artist. Bon vivant.

-

-

06-01-2019, 04:48 PM #805

-

06-01-2019, 05:16 PM #806

it's not wood but horn. the former owner cleaned it with an abrasive. Traces give the impression that there are fibers. I repolished it gently so as not to erase the precious inscriptions. Could you give a date of manufacture for this razor?

Your article on tin is really complete and interesting, thanksLast edited by lohar; 06-01-2019 at 05:19 PM.

-

The Following User Says Thank You to lohar For This Useful Post:

Voidmonster (06-01-2019)

-

06-01-2019, 11:38 PM #807

‘Ah, visually, there’s very little difference between black horn with scratches from abrasive and ebony!

That style seems to have been made from about 1805 to 1820, more or less.

The earlier end I know because Joseph Hives made them and he died in 1807, 1820 is about where Clark & Hall ended and I’ve seen a few others of that style from other manufacturers who were in operation in the early 1820’s.-Zak Jarvis. Writer. Artist. Bon vivant.

-

-

06-02-2019, 12:20 PM #808

Thank you! I've been very interested in seeing any form of expansion on that clever doodad for sometime now, ever since you introduced it in another thread.

The detail involved with many inlays, it still boggles my mind.

...."but I have this Dremel tool, I should be able to run circles around these primitive fools... Right?"

Wrong!

As far as scale materials go, I assume those Clark & Hall scales are horn. But it reminds me of something I haven't seen discussed. I'm certain that many scales believed to be horn, were in fact baleen. You gotta work with it to be able to compare, but there are regulations...

I certainly would not advertise such infringement on regulation, also it's a sensitive subject for many.

Baleen is more fibrous, flexible and strong. Has a grain pattern.

Thank you for the info, I'm going to dig up my stubtail collection and take some pics today.

“You must unlearn what you have learned.”

“You must unlearn what you have learned.”

– Yoda

-

The Following User Says Thank You to MikeT For This Useful Post:

Fikira (06-02-2019)

-

06-02-2019, 04:04 PM #809

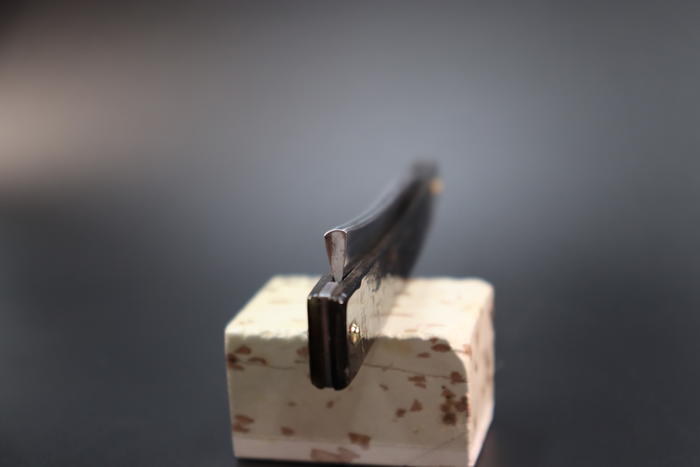

W Greaves / Warranted

W Greaves / Warranted

Believe it or not I have just restored this

-

09-22-2019, 03:58 PM #810

New acquisition. One of London's most prestigious cutlers of her time

2492Likes

2492Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote