Results 1 to 10 of 51

Thread: Tamahagane with other kanji???

Hybrid View

-

10-25-2013, 04:21 AM #1"My words are of iron..."

- Join Date

- Oct 2006

- Posts

- 1,898

Thanked: 995

Oroshigane is the selection of tamahagane from various smelts, all gauged by eye and experience, hammered into coin sized pieces, laid up on a steel plate, then welded into a billet that will become a sword. Sometimes more folding and welding are involved but it depends on the school the smith learned in. Yes, recycled material from broken swords or other tools of high quality steel have been included in billets. No good material will ever be wasted (which is a worldwide rule of smithing).

The folding is not magical. A piece of raw tamahagane comes with slags, bits of charcoal, sand, clay and voids from gas bubbles. All that has to be cleaned away from the steel and the voids closed. The cycling at welding temperatures allows the carbon content of the materials to equalize throughout the bar. The folding merely homogenizes the steel into a bar that is more useful than the raw material.

Sometimes the patterns are appreciated by those with an eye to see them. Smiths have been playing with these techniques for a couple thousand years. It's not exclusive to Japan, but the Japanese smiths exercise some of the finest work consistently.Last edited by Mike Blue; 10-25-2013 at 04:23 AM.

-

-

10-25-2013, 04:29 AM #2At this point in time...

- Join Date

- Jun 2007

- Location

- North Idaho Redoubt

- Posts

- 26,986

- Blog Entries

- 1

Thanked: 13234

Man I love when Mike talks steel, I learn something everytime

-

The Following User Says Thank You to gssixgun For This Useful Post:

Mike Blue (10-25-2013)

-

10-25-2013, 02:46 PM #3

Amazing words... Beautiful, thank you!

Amazing words... Beautiful, thank you!

So, is it possible that this kami is made from previous Tamahagane swords and thus is about the same quality?

Or is there a great possibility it is made of "regular" steel, that is folded? How can you know?

Is it a wright assumption that, if a smith made this kami of recycled Tamahagane, he may not stamp it with a Tamahagane kanji?

-

10-25-2013, 07:05 PM #4"My words are of iron..."

- Join Date

- Oct 2006

- Posts

- 1,898

Thanked: 995

Without being able to talk to the smith who made the bar of steel, nothing is certain. Asking the person who made the steel would be the most direct and accurate means to answer your question.

We could subject the blade to destructive testing, say spectrographic analysis, and could probably discriminate between a very clean simple steel like tamahagane and a modern alloy, but some modern alloys are very clean and simple too.

It is possible that this blade is pattern welded regular steels. See above answers.

As Glen indicated, this type of steel has its own value. I can't imagine going to the trouble of using a fairly rare material and then not taking credit for it. Even pattern welded material should be more valuable than say a mono-steel. You have to recover the cost of the materials, the cost of the labor involved (as these are custom hand processes for the most part), some of the aesthetic involved in creating the work and the smith's reputation for working in an above-average material. But, the smith could have died and the blade wasn't stamped. Given the possibility that there are flaws in the blade, he may not have wanted it marked as his work and suffered some damage to his reputation. It could have been a master's student's work and not good enough for a signature. As I suggested though, the flaws I see are not fatal and while they would not be considered perfect work, you still have an acceptably adequate working tool to use too. Value laden objects are subject to too many variables.

-

10-25-2013, 07:46 PM #5

-

10-26-2013, 07:57 PM #6

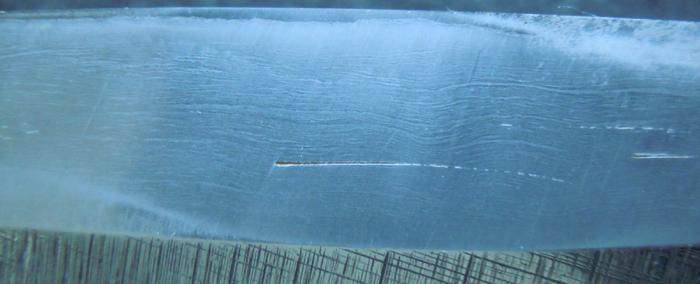

Just for the record, some photo's at the "end" of the honing progression, not what I would like it to be, but it seems to be a "smiling" kami,so it wasn't easy to hone some areas, got an overall HHT 4 though, so at the moment I'm satisfied

(The pic below keeps turning upside down for some reason...)

Last edited by Fikira; 10-26-2013 at 08:09 PM.

-

10-26-2013, 11:56 PM #7

How do I put this politely ?

The geometry of this razor is wrong. Sorry.

The geometry of this razor is wrong. Sorry.

The ridge should actually be a straight line which in turn would give you a straight edge.

Someone has 'restored' this razor not taking that into consideration but congrats on prolonging it's life & getting it shaving.Last edited by onimaru55; 10-26-2013 at 11:59 PM.

“The white gleam of swords, not the black ink of books, clears doubts and uncertainties and bleak outlooks.”

-

10-27-2013, 08:52 AM #8

No problem at all! It's the only one in my kami collection with such a geometry and I thought it wasn't wright, now I'm sure!

Maybe it is restored or maybe the possibility, given by Mike Blue, of (maybe) being a master's student's work that wasn't good enough, is becoming more possible?

Thanks for your compliment!

Kindest regards

-

10-27-2013, 02:59 PM #9"My words are of iron..."

- Join Date

- Oct 2006

- Posts

- 1,898

Thanked: 995

Oz, what are your thoughts about the possibility that this may have simply been only partially ground to completion and not a "restore." Once taken to the wheel to grind and those flaws show up in the middle and it got tossed onto the recycle pile, only to slip out of the shop and wind up in the hands of the public? it would explain the half finished way it looks to my eye. You fellows who look at these a lot more than I will have a better idea though.

24Likes

24Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote