Results 31 to 40 of 55

-

01-29-2014, 12:36 AM #31

So how about the TI razors that were supposedly immersed in molten lead to temper them?

Would there be Pb in the metal of the razor?

-

01-29-2014, 12:38 AM #32Historically Inquisitive

- Join Date

- Aug 2011

- Location

- Upstate New York

- Posts

- 5,782

- Blog Entries

- 1

Thanked: 4249

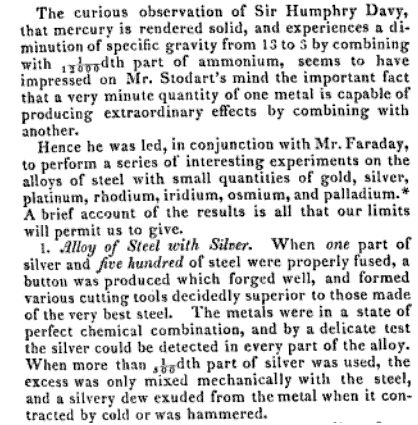

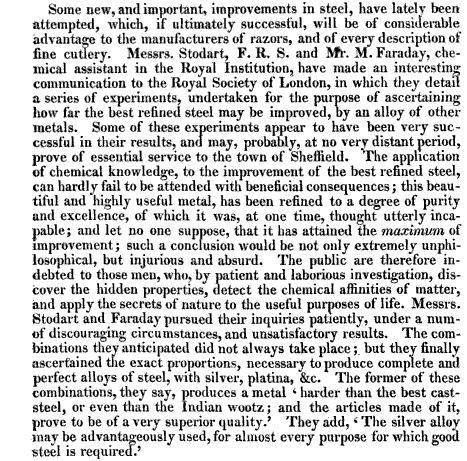

Its been very clear to me that Faraday "Silver steel" did in fact contain real silver, 1 part of silver and 500 part of steel.

Actually its been printed in books for almost 200 years.

It would be very interesting to have "Science Guy" test the newer steel as well.

-

01-29-2014, 12:41 AM #33

No the lead falls off. It might leave a micro layer but nothing of any worth, And the steel when it goes into the lead bath is not molten. They use the lead because it can be heated to a specific temp and it draws the heat from the metal faster than oil or water (better thermal conductivity). Meaning in theory they have better control over the internal crystal growth of the steel when they temper it. TI's system doesn't attempt to alloy lead with steel, and if it left more than a micro trace I think the practice would be banned. They had to get special permission to use that system, and prove it didn't leave a dangerous trace.So how about the TI razors that were supposedly immersed in molten lead to temper them?

No the lead falls off. It might leave a micro layer but nothing of any worth, And the steel when it goes into the lead bath is not molten. They use the lead because it can be heated to a specific temp and it draws the heat from the metal faster than oil or water (better thermal conductivity). Meaning in theory they have better control over the internal crystal growth of the steel when they temper it. TI's system doesn't attempt to alloy lead with steel, and if it left more than a micro trace I think the practice would be banned. They had to get special permission to use that system, and prove it didn't leave a dangerous trace.So how about the TI razors that were supposedly immersed in molten lead to temper them?

Would there be Pb in the metal of the razor?Last edited by Iceni; 01-29-2014 at 12:50 AM.

-

01-29-2014, 12:52 AM #34"My words are of iron..."

- Join Date

- Oct 2006

- Posts

- 1,898

Thanked: 995

I will debate that the name silver steel does not represent an alloy of silver and steel. Silver oxidizes which would defeat the purpose of a stain resistant blade. Adding a material that does not harden would make no sense in a blade you want to harden. Even Faraday admitted that he could not get more than a minor percentage (0.2% with the bulk of silver forming globules or distributed around the crucible) to alloy. Francis (1842) suggests that only 1 part silver to 500 parts steel will alloy as chemicals and anything greater will be merely a mechanical mixture of the two. For the most part such experiments were abandoned by the mid 1840's. Steels like drill rod will take a high polish or burnish and as polished have more resistance to etching or oxidation. I think the rust resistance is coincidental to an attribute not well understood at the time. Some very clean, very well manufactured steels came out of this manufacturing era. A silver alloyed steel did not stand the test of time.

In re the other thread, I would first suspect a bluing technique to produce the black color, before a minimal amount of silver. Even then that would be more common than the very few numbers of Faraday's own steel mixtures.

-

01-29-2014, 12:57 AM #35"My words are of iron..."

- Join Date

- Oct 2006

- Posts

- 1,898

Thanked: 995

It's more about the precise thermal control that a lead bath offers and limiting exposure to oxygen present in oil and water. Crystalline changes would be more likely to occur at greater than necessary temperatures for forging. and those are far above those used for hardening.

-

01-29-2014, 02:27 AM #36

Uhh... Based on the stories that I've sold, I have a feeling ScienceGuy would prefer to remain safely outside my fiction. (look up the table of contents here.)

-Zak Jarvis. Writer. Artist. Bon vivant.

-

01-29-2014, 02:39 AM #37

Also, the lead bath thing goes back to Stodart (and I think he got it from somewhere).

When he was using it, like Mike Blue says, it was for precise temperature control.

Imagine the setup this way:

The lead expands as it heats, and can obviously be heated above its simple melting point. Because of the expansion, you can keep it in a crucible with level marks notched in. When the thermal expansion causes the level to rise to the notch that you know represents the best temperature for hardening the steel, you know every time the steel goes in that it's going to get uniformly heated to that amount.-Zak Jarvis. Writer. Artist. Bon vivant.

-

01-29-2014, 03:19 AM #38

-

01-29-2014, 08:53 AM #39

You're just old romantics

Nickel silver on the other hand....

-

01-29-2014, 11:47 AM #40

86Likes

86Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote