Results 1 to 10 of 32

Hybrid View

-

11-11-2014, 08:46 PM #1

Laminated steel on frameback J.A. Hellberg?

Laminated steel on frameback J.A. Hellberg?

Hi,

One of my last purchases includes a frameback J.A. Hellberg

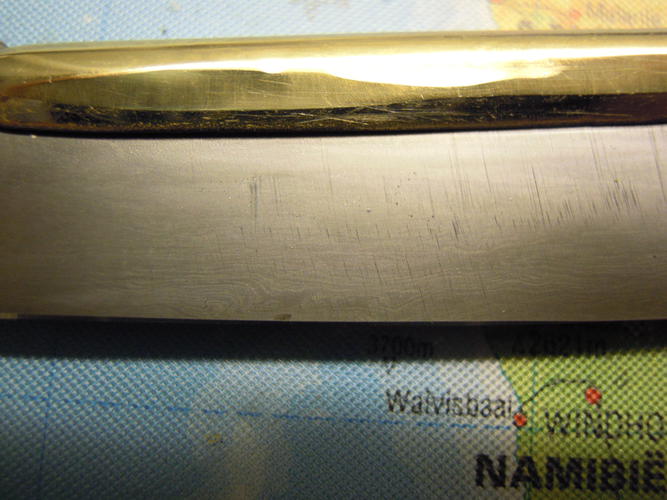

It has laminated steel as seen on pics, I first thought it wasn't real but

after polishing one side, the pattern didn't disappear, it even came more to life,

it's very hard steel and easy to get a incredible sharp edge! I have never had a razor that is SO SHARP,and easy to hone, really HHT 5!

When googling, I found no "laminated Swedish frameback's"

Does anyone know anything about them?

The razor has "Trolhätte Diamond steel" stamped on the spine,

I need to clean it up more, and put some new scales on it, couldn't wait to post this...

Thanks!Last edited by Fikira; 11-11-2014 at 08:49 PM.

-

11-11-2014, 09:15 PM #2Senior Member

- Join Date

- Jan 2011

- Location

- Roseville,Kali

- Posts

- 10,432

Thanked: 2027

If truly Laminted,put some ferric chloride on it,will make it truly show the laminations.

CAUTION

Dangerous within 1 Mile

-

11-11-2014, 10:11 PM #3Senior Member

- Join Date

- Mar 2013

- Location

- Sydney Australia

- Posts

- 173

Thanked: 40

I don’t think that it is laminated in the modern sense (the deliberate use of different steel alloys to produce contrasting layers, i.e. pattern welding).

Rather it is an artefact of the steel production, using the cementation process to form blister steel bars, which were then processed into shear steel by forge welding (Cementation process - Wikipedia, the free encyclopedia and Crucible steel - Wikipedia, the free encyclopedia @ blister steel).

I believe the subtle pattern is due to the very slight difference in the alloy (as a result of the impurities) of each of the blister steel bars. This effect (and the cause) is similar to that seen in traditional Japanese swords.Last edited by DrDalton; 11-11-2014 at 10:18 PM. Reason: added a further link to blister steel

-

-

11-12-2014, 03:26 PM #4

-

01-25-2015, 08:59 PM #5

-

01-25-2015, 09:03 PM #6

Take care or the framebacks, please..

-

01-25-2015, 09:23 PM #7

I would love to have one. I have several Swedish straights, two of them Hellberg's but not framebacks. I have a Jon Engstrom brass frameback which is a nice little razor. I have a few C.V. Heljestrand's. I'll have to be for the lookout for one. It's a cool razor!

-

The Following User Says Thank You to engine46 For This Useful Post:

Fikira (01-25-2015)

-

01-25-2015, 09:25 PM #8

-

11-11-2014, 10:14 PM #9"My words are of iron..."

- Join Date

- Oct 2006

- Posts

- 1,898

Thanked: 995

The ferric chloride isn't really needed, but if you did use some, the stuff that is there will show up better than it does now. Polish out all those scratches first. The eye has seen the pattern. I think this stuff is pretty cool. I really enjoy the subtlety of the bands.

The material is most likely crucible steel of some kind and the feature you can clearly see is called alloy banding. There are several ways this could occur but it's not from laminating steels together as the modern pattern welders do it.

One possibility is that this is a form of shear steel but I'd give that an outside chance when alloy banding can occur with a lot less work. Strangely enough the alloy bands can be manipulated in the same fashion that PW makers can make pools or eyes or ladders.

Very cool razor.

-

-

11-11-2014, 11:07 PM #10Senior Member

- Join Date

- Jan 2011

- Location

- Roseville,Kali

- Posts

- 10,432

Thanked: 2027

I think using a little FC would make that blade Really pop.JMO

CAUTION

Dangerous within 1 Mile

-

The Following User Says Thank You to pixelfixed For This Useful Post:

Fikira (11-12-2014)

43Likes

43Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote