Results 1 to 6 of 6

-

11-22-2014, 08:08 AM #1

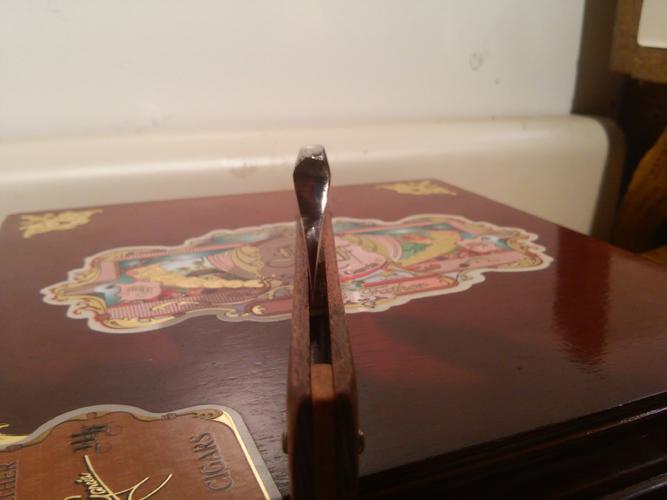

Behold - My Wade and Butcher 15/16th smiling wedge!

Behold - My Wade and Butcher 15/16th smiling wedge!

Got it last week, finally pinned the new scales on it. My first piece of Sheffield steel, and my first wedge. Its absolutely fresh, hone wear is minimal, and very even. Edge has a good bevel on it. a few stains, but pretty much no rust, some one has scrubbed it with something abrasive, but i didn't have the heart to nuke out the original finish by sanding it, so i just rubbed it down with some Maas.

Next step is some honing to bring it up to a shaving edge. I've been honing razors for a year, but every thing i have is hollow ground, so im a little nervous about putting it to the stone, just finished up on gssixguns honing tutorial for smile wedges, would love to find some more info though and watch some more tutorials before i go at it.

Hope you guys enjoy, sorry for the shit pics using a phone camera.

-

11-22-2014, 11:15 AM #2

Put it to the stone, looks like this is actually about a quarter hollow ground, it just kind of hard to see.

Having some serious problem getting it to take a bevel though

-

11-22-2014, 01:32 PM #3Senior Member

- Join Date

- Mar 2012

- Location

- Thunder Bay, Ontario, Canada

- Posts

- 17,350

Thanked: 3228

What kind of problems exactly?

BobLife is a terminal illness in the end

-

11-22-2014, 03:00 PM #4Senior Member

- Join Date

- Feb 2013

- Location

- Haida Gwaii, British Columbia, Canada

- Posts

- 14,457

Thanked: 4830

It takes a lot longer to make a new bevel than it does to repair a damaged one. Getting to the bevel being perfect is a long road. Tape is my friend when it comes to bevel string on heavy ground razors. I will start with two or three pieces and drop one near the end. I often change that top piece several time in the process. They don't always get done in a single sitting either. Some use DMT's or less than 1K hones to start it. I always just stick with the 1K as it has given good results,but you have to be patient. The project looks good. It does have very crisp lines.

It's not what you know, it's who you take fishing!

-

The Following User Says Thank You to RezDog For This Useful Post:

Daekkon (11-22-2014)

-

11-22-2014, 11:00 PM #5

Bevel is more uneven that i originally thought, it tapers to the heel on oneside, and its flatter in the middle on the other. the grind also leans to one side at the heel (like alot of old sheffields)

Coming from honing hollows and extra hollows this is a whole nother world.

-

11-23-2014, 12:24 AM #6

Last edited by Daekkon; 11-23-2014 at 12:46 AM.

10Likes

10Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote