Results 1 to 10 of 15

-

11-08-2015, 12:46 AM #1

JA Henkels find... seeking suggestions

JA Henkels find... seeking suggestions

Hi,

A friend told me a local antique shop had a bunch of razors, so I decided to take a look. I found a nice looking Wade and Butcher that had etching saying something about "You...I'll shave your face". The blade look really nice, but the scales were broken (piece missing at pin) and they wanted $65.

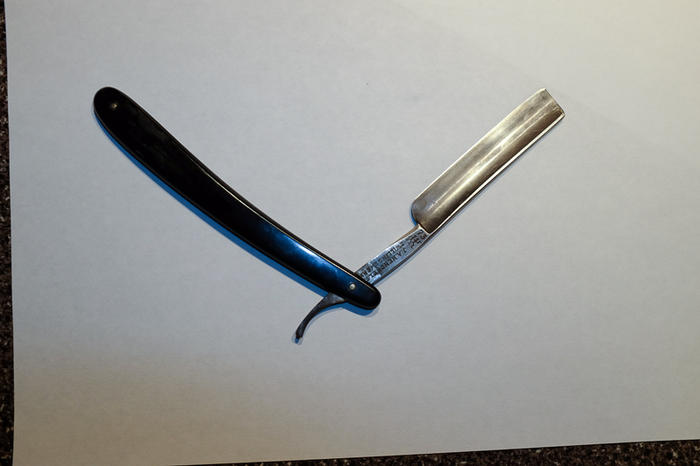

I then found this JA Henkels (1/2 wedge?) and decided to pick it up. Any info on the blade would be appreciated. It says ZWillingswerk and the number 73 on it. The scales were in great condition, tight, and blade centered. The blade seems ok, given my untrained eye, so I'd like to hear what people's thoughts are on the blade condition, whether I'm missing something really bad, and how I should remedy any issues.

Here's both sides, unmagnified. Seems like moderate wear on spine, seems pretty straight, which as slight taper towards toe.

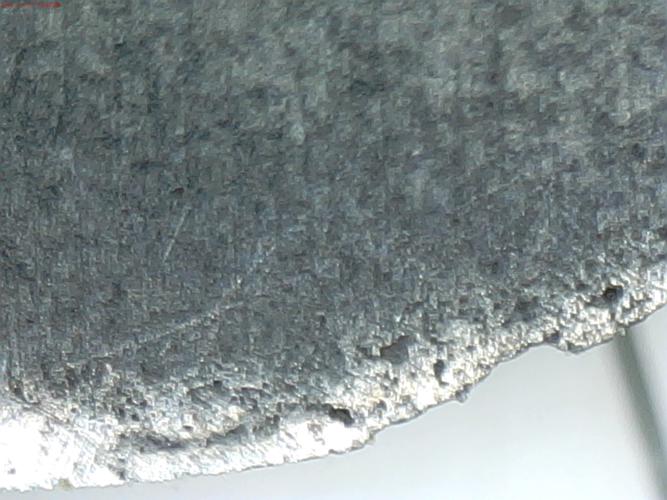

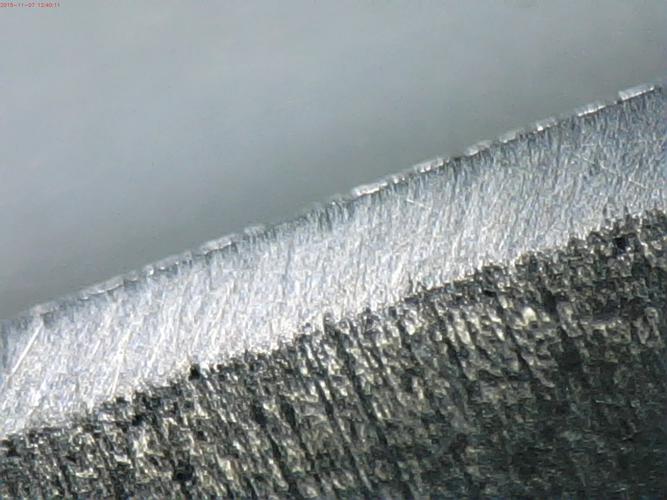

Under high magnification, I see a 2-3mm ding at the very heel:

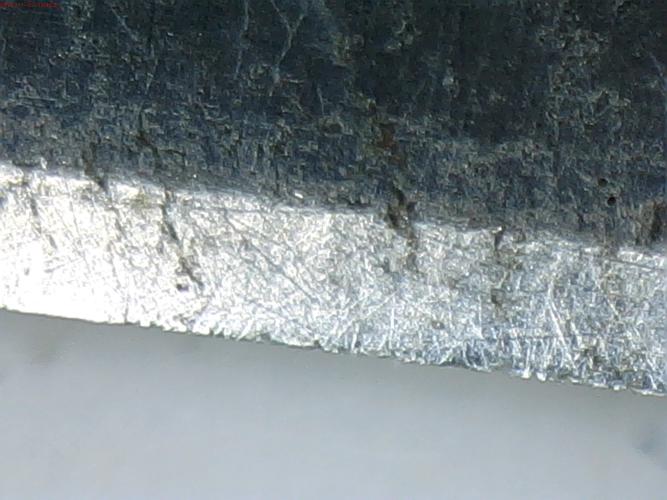

Most of the edge seems OK (other than probably needing bevel set):

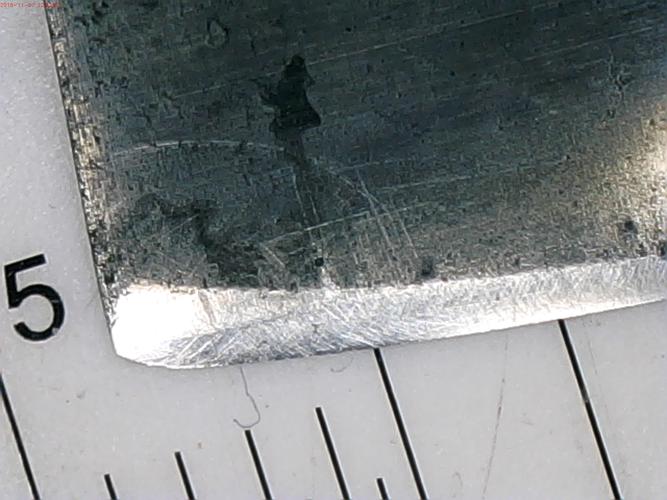

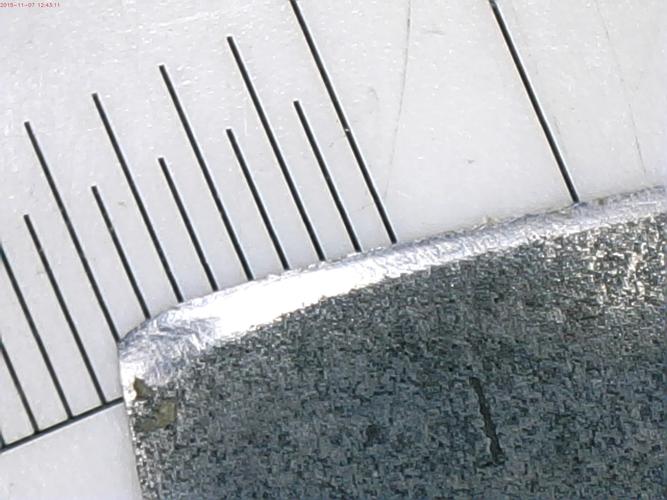

The edge is mostly 1mm (the ruler marks in the second shot are 1mm), except near the toe. It does cut arm hair on 1/2 the blade from the toe end. At the toe, there is another ding:

I'm not sure of the black spots. anyone know what that is? Is there a way to clean it?

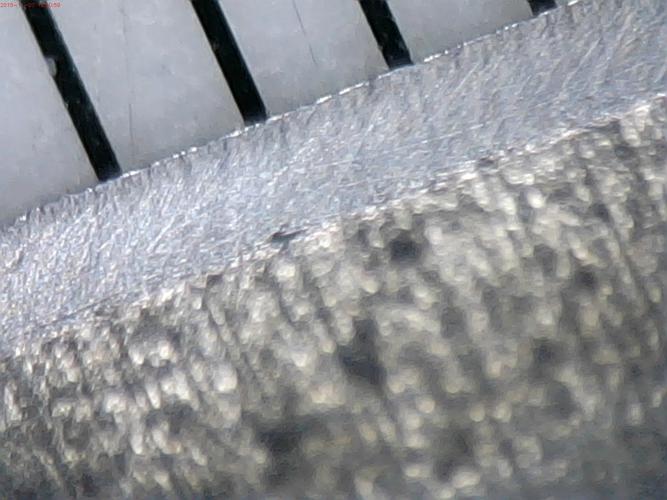

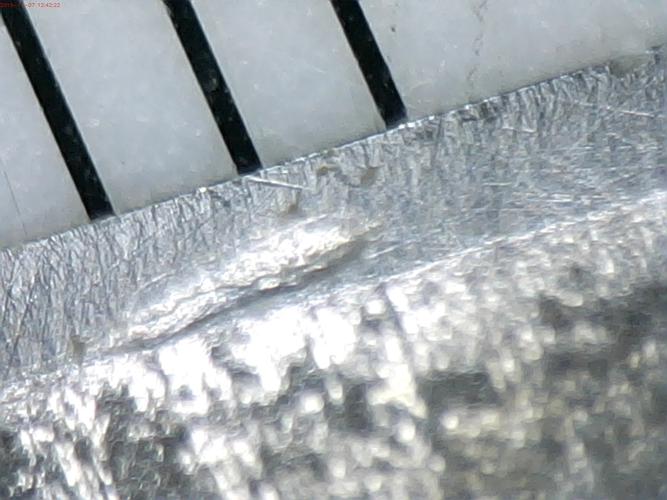

Lastly, there is one 2mm long and maybe .25mm wide divot on the edge, kinda odd:

Do I need to try to hone that away or just let it go?

There is some water like spots on the blade. Small, some discoloration, only on one side. What would one to do address that?

Suggestions on how I should resolve the ding at the heel? The divot?

Anything I need to address with the blade in general?

Should I just try setting the bevel (with tape on spine) and shaving to see how it goes?

I don't have the tools or knowledge to "restore" blades, so I have some limitations on what I can do, but I wouldn't mind seeing if I can resurrect this blade for daily use, and learn more about maybe some of the basics of restoring blades.

Not sure what I'm getting into, but this is a $20 experiment, that I thought I'd give a try at. No great hardship if it doesn't work out.

Looking to hear what people think! Thanks!Regards,

PCM

-

11-08-2015, 01:49 AM #2Senior Member

- Join Date

- Feb 2013

- Location

- Haida Gwaii, British Columbia, Canada

- Posts

- 14,455

Thanked: 4830

The condition does not look like it is something to toss. It is likely going to take a bit of material removal to get a nice clean bevel. The brand is good so as long as that edge holds up to a honing it is clean sailing. The metal at the heel is weak that is why it is chippy like that. Give it a go.

It's not what you know, it's who you take fishing!

-

The Following User Says Thank You to RezDog For This Useful Post:

pcm (11-08-2015)

-

11-08-2015, 03:27 PM #3

Do you think through the honing process, I'll get rid of that divot, in the last shot? Will it matter?

What should I use to disinfect the blade, before using it?

Should I do anything about the pitting? black marks on the blade in general?

Should I breadknife the blade and then hone? Should I go right to 1K?

I have Norton 1,4,8K, and 12K SS, crox past on webbed strop, to work with here.

Thanks!Regards,

PCM

-

11-08-2015, 03:39 PM #4Senior Member

- Join Date

- Feb 2013

- Location

- Haida Gwaii, British Columbia, Canada

- Posts

- 14,455

Thanked: 4830

I am not a fan of bread knifing. Rubbing alcohol is fine for disinfecting razors. I would set a bevel and make sure it is fresh steel. Use the 1K, it will take some effort. Tape the spine. If you start with three layers of tape it will bring the angle up and cut a little faster, then reduce to one layer once it has a good clean bevel. You will likely have to hone past the ugliness. Once you have a bevel set you cn dull the edge and clean the blade up with steel wool and mothers polish.

It's not what you know, it's who you take fishing!

-

The Following User Says Thank You to RezDog For This Useful Post:

pcm (11-08-2015)

-

11-08-2015, 04:33 PM #5Senior Member

- Join Date

- Mar 2012

- Location

- Thunder Bay, Ontario, Canada

- Posts

- 17,334

Thanked: 3228

I'd go with what RezDog suggested. The black spots are "devils spit" or inactive rust with pitting underneath. When they are near the bevel or go down into it they will leave chips on the edge when you start removing metal during honing. You will have to hone until you get good solid steel for the bevel. It takes a bit of work but you should get there.

BobLife is a terminal illness in the end

-

The Following User Says Thank You to BobH For This Useful Post:

pcm (11-08-2015)

-

11-08-2015, 06:33 PM #6

Thanks @RezDog. I cleaned up the scales and blade using Q-tips and paper towels with hydrogen peroxide (didn't have alcohol handy). I took some oil I got from SRD and rubbed down the blade, and used more Q-tips and oiled paper towel and tooth picks to try to get in near where the tang meets the pin. Got some dirt and seems like some some surface rust off that area. Looks reasonable.

Figured, I'd leave it oiled, until I decided what to do with it. Appreciate the ideas on how to attack this "project" blade. Worst case, I get practice honing, as I've only honed twice before. Once to fix small ding on a new Dovo, and one to sharpen up my Union Cutlery Spike (which took forever, but came out pretty good).

+1 on taping, as I did wear my Spike's spine, being new at honing and probably too much pressure, until I heard about the taping. Can you elaborate on the polish? Car polish? It looks like Mothers has several.Regards,

PCM

-

11-08-2015, 06:34 PM #7

-

11-08-2015, 06:42 PM #8Senior Member

- Join Date

- Mar 2012

- Location

- Thunder Bay, Ontario, Canada

- Posts

- 17,334

Thanked: 3228 Life is a terminal illness in the end

Life is a terminal illness in the end

-

The Following User Says Thank You to BobH For This Useful Post:

pcm (11-09-2015)

-

11-08-2015, 07:54 PM #9Senior Member

- Join Date

- Feb 2013

- Location

- Haida Gwaii, British Columbia, Canada

- Posts

- 14,455

Thanked: 4830

It does not matter which metal polish you use really. I would say use the one that is most convenient to buy. I use mothers aluminum and mag wheel polish. As for steel wool the 0000 is the finest. You can start with that. It will take off the black and leave the pits. The downside of that approach is that it definitely requires a lot of elbow grease. It works well and is very inexpensive.

-

The Following User Says Thank You to RezDog For This Useful Post:

pcm (11-09-2015)

-

11-08-2015, 09:43 PM #10

+1 it can be saved for sure

as mentioned above the 3rd close up with the pitting etc to the edge is more of a concern than the chips that will hone out

getting back to clean steel is a must,

you think it would be ok but those tiny divots will be chippy & potentially crack if left, but most of all your face will feel them as they will feel like a serrated blade on your face & like the hairs are getting plucked,

Yes I found this out the hard way prior to getting a loupe & then realizing why a certain blade was so ANGRY but once honed to a full clean edge the blade was fine.

I personally don't fully bread knife & just hone away until it is good steel unless I am reshaping the blade completely

you can hone at a higher angle get to a clean edge quicker but you still have to remove all the bevel anyway

look forward to seeing you progress.Saved,

to shave another day.

-

The Following User Says Thank You to Substance For This Useful Post:

pcm (11-09-2015)

9Likes

9Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote