Results 11 to 20 of 25

-

11-25-2015, 05:11 PM #11

To the best of my knowledge, there were no razors made with Damascus steel.

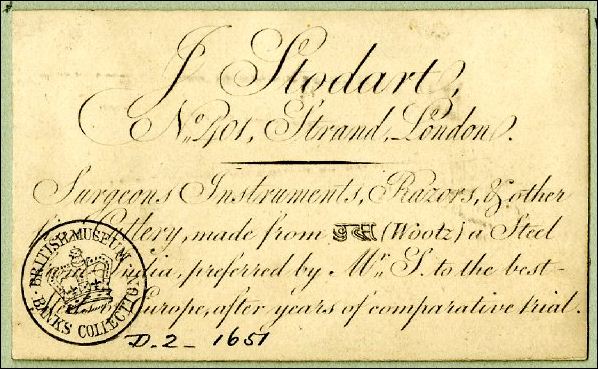

James Stodart and Joseph Rodgers both advertised using Devangari script to claim they were using 'wootz' steel, but none of them exhibited the characteristic patterning of real Damascus steel.

George Wostenholm and several different French manufacturers produced blades with etchings meant to mimic the look, but it was wholly artificial. It was done by painting or stamping the pattern onto the blade with something that resisted acid, then painting a highly corrosive acid over top that. The patterning was not a feature of the metal itself, but a decoration put on top of it.

The lancets that Thaeris showed pictures of are corroded by blood left on the blades. It's a very typical pattern when liquid is left on the steel, and not a sign of patterning.

An example I have:

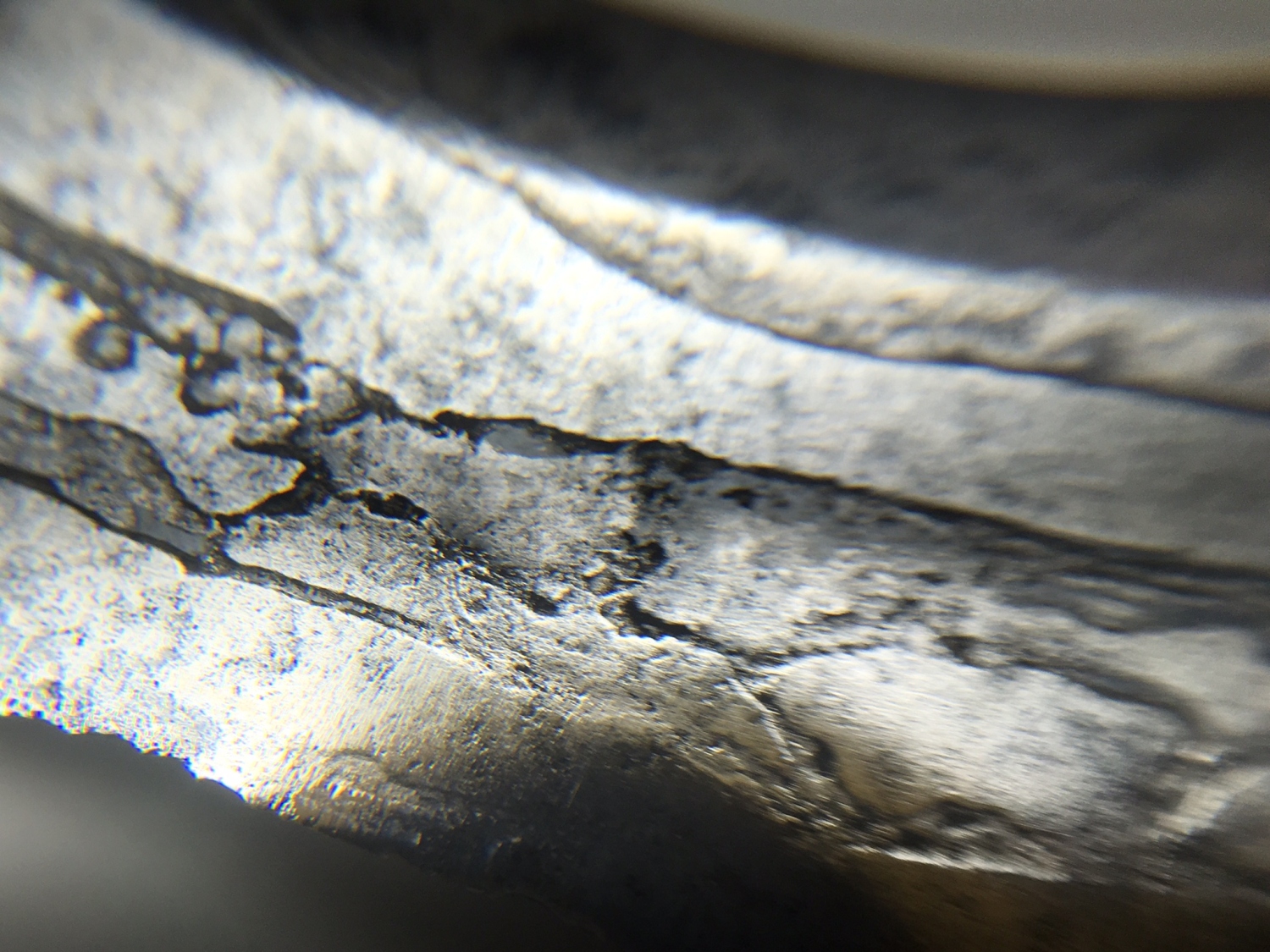

This razor was corroded by someone dying the scales black without any care for keeping the dye off the blade. You can clearly see the liquid patterns where the scales were pressed against the steel.

A closeup of the damage:

This is a picture of the real deal:

-Zak Jarvis. Writer. Artist. Bon vivant.

-Zak Jarvis. Writer. Artist. Bon vivant.

-

-

11-25-2015, 06:27 PM #12

Last edited by engine46; 11-25-2015 at 06:36 PM.

-

11-25-2015, 10:11 PM #13

Surely the layered effect is not relevant to whether the steel is Wootz or not?

-

11-26-2015, 04:28 PM #14

At the most pedantic -- going back to word origins, the misunderstood word wook derived from ukku, supposedly meaning 'melted' -- you could argue that it doesn't matter. However, since the late 1700's it's been understood that wootz specifically referred to steel that exhibits that exact patterning. Damascus is inarguable.

It is not the same thing as pattern welded steel. Rather, it's steel that is poured out of the crucible and shaped like any other, but exhibits that characteristic pattern. Pattern welded steel, as often seen in fancy custom knives and high end kitchen knives, is made very differently. There's lots of Youtube videos of how it's done, but the short version is that the pattern is created in the process of welding multiple different steel formulations together and then giving the finished product a light acid bath to show off the different layers. Real wootz is a single-source steel of one formulation.-Zak Jarvis. Writer. Artist. Bon vivant.

-

The Following User Says Thank You to Voidmonster For This Useful Post:

Geezer (08-20-2018)

-

11-30-2015, 01:01 PM #15

To add just a bit to this, it has been speculated that impurities could play an important role in the formation of patterning and properties upon cooling. Also, some people have done some characterization on authentic damascus samples and found nanomaterials inside: http://www.hefajstos.agh.edu.pl/files/[2006]%20Carbon%20nanotubes%20in%20an%20ancient%20Damasc us%20sabre%20-%20M.%20Reibold.pdf

-

The Following User Says Thank You to ScienceGuy For This Useful Post:

Voidmonster (12-01-2015)

-

12-07-2015, 08:11 PM #16Junior Member

- Join Date

- Mar 2012

- Location

- Switzerland

- Posts

- 7

Thanked: 0 Léthien's guaranteed true Damascus razor blades

Léthien's guaranteed true Damascus razor blades

In a gazette from the year 1787 I found the note that the French cutler Léthien sold “guaranteed true Damascus” razors (vrai Damas à garantie) for up to two and a half times the price of his “mechanical Damascus” razor blades (damas corroyé & raffiné au feu).

This differentiation between “true Damascus” and “mechanical Damascus” is notable and begs the question what kind of steel Léthien used to produce these “guaranteed true Damascus blades”.

I found an earlier source documenting that Léthien imported Damascus sabres from Constantinople in 1786 to make knives “dites à coulisse”.

From this I conclude that the said “guaranteed true Damascus” razors were also made from these sabres and as such are possibly the first West European razor blades to be made of true Damascus steel.

My aim is to find an example of one of these Léthien “guaranteed true Damascus” blades. I would be grateful to anyone who can assist me in my search.

Thanks

Richard RechsteinerLast edited by Longbow64; 12-07-2015 at 08:16 PM.

-

05-25-2016, 01:43 PM #17

I just acquired a set of four of these. I'm not sure if they are simply pattern welded or more like real damascus, but they are very interesting regardless. As best I know Lichtenberger was a cutler active in Strasbourg, possibly during the Empire period. Anyway, here are some pictures of the steel.

-

05-25-2016, 02:38 PM #18

I don't know if this is true or imitation. I cannot feel it with a fingernail. I suspect imitation..

Horn scales, dealt by Curley of NY.

"Don't be stubborn. You are missing out."

"Don't be stubborn. You are missing out."

I rest my case.

-

05-29-2016, 02:52 PM #19

In my opinion, those are. I had a knife from Lichtenberger, it seemed to be a quite nice family of cutlers and surgeon tools makers.

This Lecollier however has an acid etched blade, not damascus. A quite common practice on french framebacks

I don't know however if at the time the "damas" they were talking about was only wootz cast steel, or if it involved the modern notion of simply different kind of steel twisted and worked together.

If so it would seems quite natural to have some odd paterns, not looking like vintage wootz at all.

-

The Following 2 Users Say Thank You to Thaeris For This Useful Post:

engine46 (08-20-2018), ScienceGuy (05-31-2016)

-

08-20-2018, 05:54 PM #20

Perret's razor ( no damascus blade)

-

The Following User Says Thank You to lohar For This Useful Post:

ScienceGuy (08-20-2018)

57Likes

57Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote