Results 1 to 10 of 40

Thread: Wade and Butcher Irontusk

Hybrid View

-

09-05-2016, 01:51 PM #1

yes that's correct. In this case the PM steel is produced in strip form and supplied to us for stock-removal processing.

Can you imagine trying to form the razor into near-net-shape using expensive dies etc. That is quite a crazy assumption an earlier poster jumped to...

No, we simply receive the strip steel from Damasteel and grind away everything that isn't a straight razor, then heat-treat and finish-grind and polish..

These are high-end handcrafted precision shaving implements after all - not pre-formed items of cheap jewellery

But I'm so glad folks are now on the right page

Cheers,

- Mike

-

The Following User Says Thank You to MichaelC For This Useful Post:

BobH (09-05-2016)

-

09-05-2016, 02:48 PM #2

To be honest I don't see much difference between a near net shape form and stock removal of PM steel, the process to make the steel itself is still the same. I would consider them equally precise methods, as near-net-shape processes will require some final grinding at the end as well. (and I'm not sure about the knife/razor maker world, but to anyone who has experience/a degree in metallurgy, PM does come with the general assumption of near-net-shape operations, as that is what it was originally advantageous for). Densification should be the same (near 100%) as it looks like Damasteel uses hot isostatic pressing to make their stock.

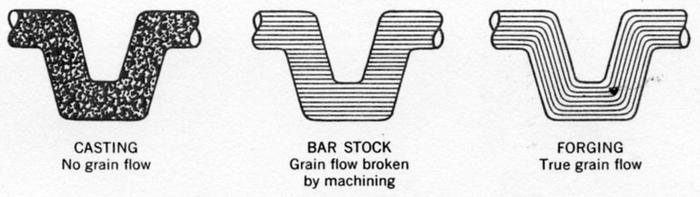

Forging the pieces is another story and achieves a different microstructure - see picture below. Though honestly I'm not sure how much the stronger grain structure of forging would be advantageous in a razor application.

-

09-07-2016, 05:19 PM #3Senior Member

- Join Date

- Aug 2014

- Location

- East Central Illinois

- Posts

- 782

Thanked: 101

So the question begs, are you going to forge blades besides the stock removal method? I don't know if any W&B razors were not forged. You are getting farther from a real W&B razor all the time. Yes you own the name but I really believe you will sell more razors using traditional materials & methods.

Don't get me wrong.I think what you are doing is great. Attaching the Wade & Butcher name to it might be a stretch. If one of your razors will shave smoother than my 1860's - 1870's W&B hollow ground I might buy one.

Slawman

Last edited by Slawman; 09-08-2016 at 01:25 PM.

-

09-07-2016, 06:28 PM #4

Mehhhh everybody's a metallurgist hahaa

Mike, If you were forging old Sheffield steel found in a bunker someone would cry the hammer was not 200 yrs old, or the old bird swinging it wasn't an Englishman lol

Love my old W&Bs but modern methods and materials will produce a superior product. Luckily there are plenty of old ones kicking around if the new W&B isn't someones cup of tea.

I look forward to my Irontusk, will grab one asap.

-

The Following User Says Thank You to AKmik For This Useful Post:

MichaelC (09-07-2016)

-

09-07-2016, 06:49 PM #5Senior Member

- Join Date

- Aug 2014

- Location

- East Central Illinois

- Posts

- 782

Thanked: 101

I understand what you are saying. I am just saying that using the Wade & Butcher name on a product that has no relation to a real W&B other than the name does not set right with me.

They will probably be great razors & I wish them well. I just won't spend big bucks on a Wade & Butcher that AIN'T a Wade & Butcher. I don't know about the new materials & & methods making a "Better Product" A "different product"but not necessarily a better one.

David Huffman

Last edited by Slawman; 09-07-2016 at 06:56 PM.

-

The Following User Says Thank You to Slawman For This Useful Post:

scag315 (09-08-2016)

-

09-07-2016, 07:12 PM #6

Im with you, and understand what you are saying, they are long gone.

I think by bringing back THE old classic Sheffield they have set the bar very high. That is the part I respect, takes brass ones. I have a feeling that Mike knows that going in. He seems to have the vision for the brand, and the quality should be outstanding using modern methods and materials as he has described.

So far , method and materials seem on par with a high quality product coming our way. I do hope to see the classic style, shapes, and patterns used along the way.

-

09-07-2016, 08:06 PM #7

-

09-07-2016, 07:25 PM #8

I've got some really fancy antique razors that have massive forging defects in them, there's a number that have pretty warped tangs, etc. I would say not in all cases do modern methods produce better results, but it's probably a lot better controlled. Modern workers are treated a hell of a lot better too...

-

09-08-2016, 11:10 PM #9Member

- Join Date

- Nov 2015

- Location

- Mississauga, Ontario

- Posts

- 47

Thanked: 7

Gotta agree with you on all of your points. Gotta love the passion of the traditionalists [said with no ill intent] too. Wet shaving is innately traditional, and I think that is why we love it so much, and why many are quick to criticize.

I also love my collection. I am however, open to new concepts, new manufacturing techniques etc... I can see why people are looking at the use of the W&B name as a cash grab. IMO, you can say the same thing about some of the antiques out there. I've seen some pretty crappy blades with a fattened price tag simply because its an antique W&B.

-

12-24-2017, 08:15 PM #10

Well, the release date is 2017 and all I can say he's leaving it go right to the wire, or maybe it's already died a death through lack of interest.

“Wherever you’re going never take an idiot with you, you can always find one when you get there.”

86Likes

86Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote