Results 11 to 20 of 22

-

01-29-2019, 11:07 AM #11Member

- Join Date

- Dec 2018

- Posts

- 52

Thanked: 13

This looks quite good, at least in that image. I would try some polishing paste (auto stuff works well, but great only with some type of high rpm tool, like a dremel) or dmd polishing film (it's more expensive and it will wear out faster, but it's much better than fine sand paper, even auto grade). And I would start as fine as possible and see how that works first. Use a bit a oil for fine grits if you have any. Use anything with a softer cork and not fingers. Yeah, if you don't do stuff related to sharpening, cleaning and so on, you might lack things that might not be worth buying only for one razor. Hard to say.

I prefer not to take them apart as much as possible as well.

-

01-29-2019, 11:17 AM #12Junior Member

- Join Date

- Jan 2019

- Location

- U.S.

- Posts

- 7

Thanked: 1

Thank you for the warm welcome. My experience is short but intense. I have been researching wet shaving with a hands off approach for some time but have finally started the challenge of the straight. As far as the dating goes it looks as though you just date them by the picture and not the verbiage as well? I was looking at a different “map” and it dated the words along with the picture. Thank you for that clarification.

Like you said, if one is good two is better. This is the razor I picked to learn on and I really like it.

Last edited by Four82nd; 01-29-2019 at 03:14 PM.

-

01-29-2019, 12:49 PM #13Senior Member

- Join Date

- Sep 2017

- Location

- Upstate New York

- Posts

- 641

Thanked: 104

Mothers polish is great stuff. Flitz seems a little more aggressive. I use them both but honestly prefer Mothers.

-

The Following User Says Thank You to MrZ For This Useful Post:

Four82nd (01-29-2019)

-

01-29-2019, 03:11 PM #14Junior Member

- Join Date

- Jan 2019

- Location

- U.S.

- Posts

- 7

Thanked: 1

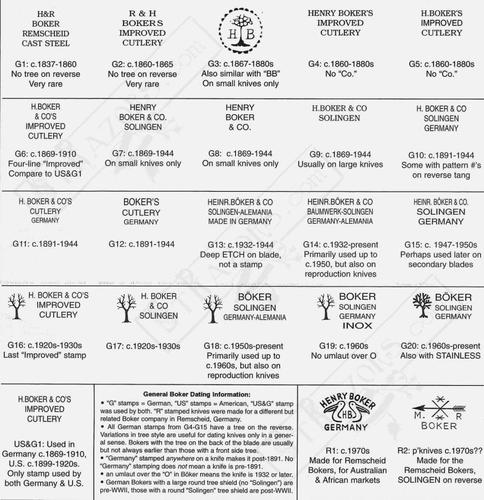

Did a little digging and found this info on identifying the age of the Boker line. Hope this is useful.

-

The Following User Says Thank You to Four82nd For This Useful Post:

jfk742 (01-30-2019)

-

01-29-2019, 05:36 PM #15

The info you posted is what i use. Its a great way to figure out the age. Unfortunately not all razor makers went this much into detail on there stamps. Some never changed besides adding the country.

The razor on top in your picture is in need of some stabilizer work. So the next time your ready to work on a razor, that would be my recommendation. Lots of info here about doing this repair. The edge should be lower than the stabilizer. What you have is a "hook" starting. A good honer would correct this BEFORE honing it. So if you send that one out for honing, ask for the repair, if you dont do it yourself.

You have a nice start. 2 is better than 1. So just wait until you break the 100 razor mark. It's just Sharpening, right?

It's just Sharpening, right?

Jerry...

-

01-29-2019, 05:44 PM #16Senior Member

- Join Date

- Apr 2012

- Location

- Diamond Bar, CA

- Posts

- 6,553

Thanked: 3215

Hose it down between the scales with WD40, let it sit a few minutes. Wrap a paper towel around a cut off wooden coffee stir sick and wipe the crud from between the scales, use the squared off end to scrape stubborn spots and at the tip of the scales at the pivot.

Scrub the blade with 000 steel wool and WD40. Wipe dry and polish the blade and scales with 000 or 0000 steel wool and any good metal polish. Flitz works well. Natural unbleached napkins polish well as does a microfiber for removing metal polish haze.

You can remove the scuff marks from the tail or on the blade with 600 wet and dry and polish with 1000 grit, then polish with metal polish.

600 grit and a wine cork will remove tarnish, and polish easily with metal polish, a quick sanding with 1k will give you a better shine. For now stay away from a Dremel.

-

The Following User Says Thank You to Euclid440 For This Useful Post:

Four82nd (01-29-2019)

-

01-29-2019, 05:56 PM #17

-

01-29-2019, 08:48 PM #18Member

- Join Date

- Dec 2018

- Posts

- 52

Thanked: 13

Well, while I didn't actually endorse the use of one, as far as performance goes, that's the way things are. I've looked into it quite a bit. Problem is, my problem, I don't really like power tools. I even prefer to do a bit less, but by my hands only. I do endorse the use of a cork and fine polishing films first. They are quite capable of removing material, but at a slower rate, making things safer for start. Since I've missed the previous reply to my own, looks like experience is not completely lacking, but still a learning razor, so going a bit over boundaries might also be a good thing. There is a very thin line between right and wrong sometimes and the best things I've learned, were by pushing a bit over the limits just to understand them better. I was able most of the times to determine an outcome before doing it, but not always and this made it worth the trouble.

I have one '20-30's, I think. Very nice razor. I really hope you will enjoy it.

-

The Following User Says Thank You to cman670 For This Useful Post:

Four82nd (01-29-2019)

-

01-30-2019, 12:42 AM #19Senior Member

- Join Date

- Apr 2012

- Location

- Diamond Bar, CA

- Posts

- 6,553

Thanked: 3215

Not saying no-one ever polished a razor with a Dremel, but many a razor has been trashed by a Dremel.

You can get just about as good a finish with 600 and 1 &2K wet and dry and any good metal polish.

Your fingers will do all a Dremel can do, only slower and safer, for the razor and you. Most of us use bench buffers and those are dangerous, but still rotating much slower than a Dremel. Buffers run at 1750 and or 3600, A Dremel runs at 35,000, yes variable speed run as low as 5,000 rpm but still almost twice the speed of a buffer.

Add to that, when you buff you are buffing below the center line of the wheel, if it grabs, it will throw down and back. With a Dremel the Rotation is reversed and you are contacting the back of the wheel. If a Dremel grabs a razor it will throw it forward and up, into your face.

When I do use a Dremel, and I do use them for some operations, not buffing, I do not stand in line with the wheel and use as slow a speed as possible. I can stand in front of a buffer all day with no problem, but still get the Heeby Jeebies with a Dremel in my hand.

No matter what you do, if you are going to work or polish a razor, I always dull the edge on a diamond file, low grit stone or 400-600 sand paper will do it. Just give the edge a couple swipes to remove the sharp edge, it will save you a nasty cut and when polishing a razor by hand or machine you will ruin the edge and it will need honing when anyway.

-

The Following User Says Thank You to Euclid440 For This Useful Post:

Four82nd (01-30-2019)

-

01-30-2019, 03:37 AM #20Member

- Join Date

- Dec 2018

- Posts

- 52

Thanked: 13

Absolutely true. Even bench buffers can be dangerous. Proper posture is a must in the first place. It's a subject on its own.

Now, I'm now super old or anything, but for these days I'm a bit of an old dog, doing my training so many years ago, when things were a lot different and procedures were something no one would dare not to learn and follow every single time. I've also learned a great deal about using power tools and why to respect them.

But I might have been misunderstood. I guess the word dremel triggered something. I've only said that those polishing auto paste types work best with power tools. And while finishing is by hand anyway, getting there with anything I've tried was not as good, not even nearly as good. I guess this is why some do use power tools. But I haven't actually said go get a dremel, a brush, cotton and polish the soul out of it. Even if it can be done. I've said quite the opposite. Cork, oil and I was in favor of a fine polishing film to start with. In fact we said pretty much the same thing, but I was only starting a bit slower to see if it's enough since it looked quite good in the picture.

-

The Following User Says Thank You to cman670 For This Useful Post:

Four82nd (01-30-2019)

58Likes

58Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote