Results 1 to 10 of 15

-

09-09-2019, 02:42 AM #1Junior Member

- Join Date

- Jul 2019

- Location

- Toronto

- Posts

- 16

Thanked: 0 Does a double shoulder sometimes start out going all the way to the edge?

Does a double shoulder sometimes start out going all the way to the edge?

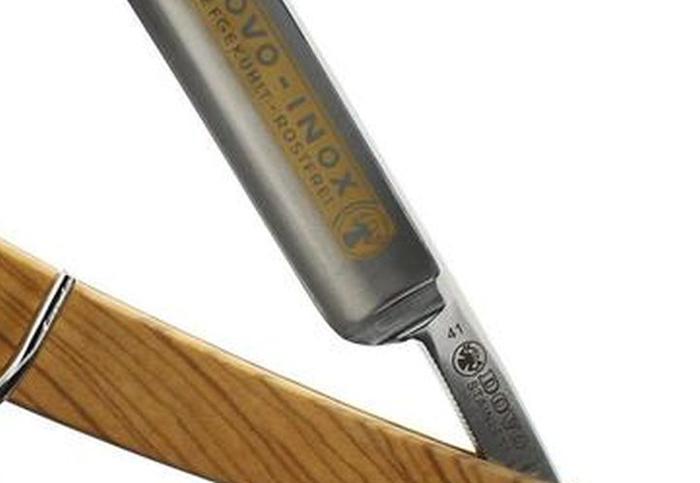

Typically I assume that when the double shoulder of a razor meets the edge, it's probably quite worn. Maybe even had the heel ground a bit. Because I expect they started out something like this:

But I do keep finding what I think are exceptions to this notion, so I'm starting to believe I'm just confused. For example... this blade doesn't have THAT much wear, does it?

-

09-09-2019, 03:06 AM #2Junior Member

- Join Date

- Jul 2019

- Location

- Toronto

- Posts

- 16

Thanked: 0

...that is a Neiström No. 62 so it occurs to me I could answer my own question by seeking out more examples of it. And yup, second shoulder sometimes goes all the way.

So much for that shortcut, guess we have to go by whether it looks reshaped, hone wear, overall condition, comparison with better specimens if available, width vs. size when new, etc.

-

09-09-2019, 03:54 AM #3

Sometimes they do, sometimes they don't, there's no set pattern.

I have had plenty blades quite new where the stabilizer went all the way to the edge. I don't like that.

I pretty much always grind a part off the shoulder on my DMT on all of my blades.

-

09-09-2019, 05:26 AM #4Senior Member

- Join Date

- Apr 2012

- Location

- Diamond Bar, CA

- Posts

- 6,553

Thanked: 3215

I assume that when the double shoulder of a razor meets the edge, it's probably quite worn.

Nope, depends on how it was ground.

Here is an advertisement photo for a new razor, notice that the edge is well into the stabilizer and will be difficult to hone properly.

A simple heel reshaping, about 30 seconds on a 300-diamond plate will reshape the heel and move the corner of the edge well forward of the stabilizer.

It is a fairly common issue and should be a routine maintenance correction when honing.

-

09-09-2019, 10:21 AM #5

I guess i've never seen that as a problem. Maybe it's the way i hone but as long as there's a radius at the heel it's never been in the way.

-

09-09-2019, 03:25 PM #6Senior Member

- Join Date

- Apr 2012

- Location

- Diamond Bar, CA

- Posts

- 6,553

Thanked: 3215

It will depend on how thick the stabilizer is, but if you were to hone the razor in the photo, the heel and probably 1/3 of the edge would be off the stone.

Most folks just add more pressure at the heel and grind the stabilizer down. You will see an uneven bevel on both sides, excessive spine wear at the heel, if tape was not used, wear marks on the stabilizer and sometimes the tang. As displayed on the second photo you posted, of the Neistrom, and that razor was ground better and the heel properly shaped.

Looking at the razor in the photo, directly up from the corner where the edge ends at the heel, you will notice is the flat of the beginning of the tang, (red arrow). That will lift the heel considerably. Hard to tell from the photo, but it appears to have wear marks on both stabilizers and the heel is not honed.

Reshaping the heel as indicated by the blue circle will move the corner forward of the stabilizer about a ¼ inch, (Green arrow). And well clear of the stabilizer and tang. The metal is very thin and easily removed. Draw a radius with a coin or large washer to keep from removing too much material and to have a pleasing shape.

There are several good posts on reshaping heels. Better quality razors will be ground more carefully as will most vintage, where time was not an issue and pride of craftsmanship was predominant.

-

09-09-2019, 09:48 PM #7

That's a lot easier fix than it sounds like. I took somebody's advice on that, it might have been Marty's in another post with an illustration and in probably 5 minutes including the head scratching and wrapping my head around it it was fixed. The previous post is a very good illustration of how to do that.

Iron by iron is sharpened, And a man sharpens the face of his friend. PR 27:17

-

09-10-2019, 09:24 PM #8

I’ve seen plenty of single shoulder straights where the shoulder went to the edge from new.

-

12-05-2019, 02:27 AM #9Junior Member

- Join Date

- Jul 2019

- Location

- Toronto

- Posts

- 16

Thanked: 0

Hm, what about this one? It doesn't seem very worn but the blade does seem to taper considerably towards the heel. Perhaps to compensate for X-strokes or, worse, those arcs that tend to wear the toe more and/or more wear from use towards the toe?

-

12-05-2019, 04:39 PM #10Senior Member

- Join Date

- Apr 2012

- Location

- Diamond Bar, CA

- Posts

- 6,553

Thanked: 3215

First, that the razor is a Heljesrand, clad in Ivory, indicates it is a quality razor and had a better than average grind from the factory. The stabilizer may be thinner near the edge. Pretty sure they were ground with the edge parallel to the spine.

But you can see that the corner of the edge at the heel, ends right at the stabilizer. You will never be able to hone to that corner unless you grind the stabilizer thin enough at the edge.

The shape of the blade may be an indicator of just that. In order to hone the heel fully, past honers have put more pressure on the heel and have ground the heel about a 1/8 th of an inch or more from the width of the toe.

The spine is straight, so it probably never had an original smiling edge, and the toe was a spike point. Past honers were heavy handed, but fortunately honed torqueing the blade, so there is not a lot of wear on the spine, but the edge has suffered and lost some width, mostly at the heel.

The edge also looks wonky, and slightly frowning, but that may be just the photo and shadow, or from too much pressure. Heljesrands are thin and it is easy to remove steel with an aggressive stone and pressure.

Re shaping the heel and moving the end of the edge forward of the stabilizer about a ¼ inch will resolve all the issues and make honing the razor much easier. The angled grind will not affect ability to shave.

-

The Following User Says Thank You to Euclid440 For This Useful Post:

HomeAwayFromHone (12-05-2019)

32Likes

32Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote