Results 1 to 10 of 19

Hybrid View

-

09-06-2020, 03:19 AM #1Senior Member

- Join Date

- Jun 2014

- Location

- Eastern Washington State USA

- Posts

- 406

Thanked: 59 Average Spine Thickness of Razors from the 1700's

Average Spine Thickness of Razors from the 1700's

As the title states, can the guys who own a few razors from that area give me the average dimensions of them. Specifically I'm most curious about the spine thickness, but length and width are appreciated as well.

-

09-06-2020, 04:03 AM #2At this point in time...

- Join Date

- Jun 2007

- Location

- North Idaho Redoubt

- Posts

- 27,130

- Blog Entries

- 1

Thanked: 13249

Man I have this info on here some place, I did it quite a few years back

Basically there are three sizes that cover most of them

4/8- 11/16

6/8

13/16 - 9/8

I have to look for the posts but basically it is 1/8 3/16 and 1/4 of course they are more exact when measured with a set of calipers"No amount of money spent on a Stone can ever replace the value of the time it takes learning to use it properly"

Very Respectfully - Glen

Proprietor - GemStar Custom Razors Honing/Restores/Regrinds Website

-

The Following User Says Thank You to gssixgun For This Useful Post:

DVW (09-06-2020)

-

09-06-2020, 04:24 AM #3Senior Member

- Join Date

- Jun 2014

- Location

- Eastern Washington State USA

- Posts

- 406

Thanked: 59

Thanks. That is a huge range. I'm assuming that they were all in the 3/1 - 4/1 ratio (width to thickness) that we still use today?

-

09-06-2020, 03:13 PM #4

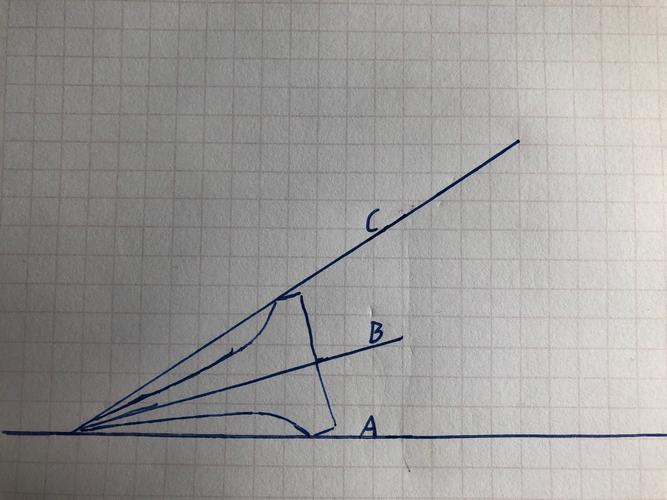

Wow. 3:1 would make for a really fat razor. Very obtuse bevel angle. But be careful of oversimplification here. The ratio between overall width and spine thickness is not the thing. The ratio of spine thickness to the distance between the edge and the highest point of the spine's contact area (call that distance, "H") is the true determination of bevel angle. Taking half the spine thickness and dividing it by H and you have the sine of half the bevel angle. Find the angle and double it, and there is your bevel angle.

As for the ancient razors, I have only personally seen and handled a couple of them that were believed to be over 200 years old. Both wedges. I don't think you will find any true hollowground razors from that era. Once the razor is a finished item, any honing would have been with the spine elevated, and so the spine thickness can be quite variable, as long as it is not too thick. How thin it can be is basically limited only by mechanical strength and rigidity concerns. Both of those stub-tails were rather thin. So thin that honing with the spine double taped would not raise the spine enough for an edge that we today would find acceptable. In fact, that is exactly why they were brought to me, the owner was honing with two layers of tape and the edge just wouldn't come in and such as it was, it did not hold up. I showed the owner what was happening with the edge at 200x and with a loupe, We spent an hour or so folding and grinding a piece of steel from a can lid to lift the spine enough to get a good bevel, honed them right up, added one layer of tape for the last few finishing laps, and huge difference. Nice clean edge, as you would expect. Bevel angle somewhere just under 17deg on the taped finishing laps. Difficult to properly measure the virtual spine thickness due to microscopic wobble of the steel spine sleeve and compressibility and wear of the tape layer, Primary bevel was not measured but would have been around 16deg. Owner went away happy, My recommendation was to just display them and not shave with them, but he was very happy that he could shave with them if desired. And I suspect that the thin spine was very typical of 1700's razors. Unfortunately I do not remember the actual measurements but I am positive the spine was not much over .100" and the blade width was at least .600", definitely over 4/8 but under 5/8. Scales appeared to be homemade replacements, pinned with an iron nail or rod. TBH they were ugly as sin, both, but interesting nonetheless.

IYAM, razors did not achieve an attractive appearance and practical geometry until the mid to late 1800's and it took the first mass production hollowgrounds to evolve the state of the art to something that really appeals to me. Those old straight-scaled stubtails to me have nothing going for them except the curiousity of being so old. Take that with a grain of salt because of my limited exposure to them.

-

09-06-2020, 03:40 PM #5Senior Member

- Join Date

- Jun 2014

- Location

- Eastern Washington State USA

- Posts

- 406

Thanked: 59 I think that you are referring to this.Wow. 3:1 would make for a really fat razor. Very obtuse bevel angle. But be careful of oversimplification here. The ratio between overall width and spine thickness is not the thing. The ratio of spine thickness to the distance between the edge and the highest point of the spine's contact area (call that distance, "H") is the true determination of bevel angle. Taking half the spine thickness and dividing it by H and you have the sine of half the bevel angle. Find the angle and double it, and there is your bevel angle.

I think that you are referring to this.Wow. 3:1 would make for a really fat razor. Very obtuse bevel angle. But be careful of oversimplification here. The ratio between overall width and spine thickness is not the thing. The ratio of spine thickness to the distance between the edge and the highest point of the spine's contact area (call that distance, "H") is the true determination of bevel angle. Taking half the spine thickness and dividing it by H and you have the sine of half the bevel angle. Find the angle and double it, and there is your bevel angle.

https://sharprazorpalace.com/honing/...ml#post1913223

and this, as example.

Yes, I do measure from the edge to the point where the spine contacts the hone, not the back of the blade. A 3/1 ratio would put you at an 18 degree angle (1 divided by 3 = 0.3333 and Tangent of .32492 = 18 degrees). A 4/1 ratio would put you at a 14 degree angle (1 divided by 4 - 0.25 and Tangent of 0.24933 = 14 degrees). So that is the range that I shoot for when making a razor. Plus or minus tape can fine tune the angle from there.

You are correct that razors of that era are almost all a wedge or a near wedge. The machine that makes the nice hollow grinds that we are familiar with wasn't invented yet.

Thanks for the information on your experience with the thin razors. I have never made a replica of a 1700's razor, but it would be fun to do. So I am just trying to get an idea on how thick to make it.

-

09-06-2020, 04:12 PM #6

Exactly. Except using the tangent introduces a small error. The tangent being the ratio between the opposite (half the spine thickness) and the Adjacent side, which is the distance between the thickest part of the spine to the edge measured right through the center of the blade. Obviously, that measurement is not directly available and so the Hypotenuse is a much handier measurement. The Hypotenuse of course being the external distance between the top of the spine's contact area and the shaving edge. And so the Sine is what is more properly solved for, and then InvSin yielding half of the bevel angle. Also some guys take a shortcut and don't use half the spine thickness. Unfortunately that, too, introduces a small error. The razor's relevant measurements describe an isoceles triangle and the direct solution is found by splitting it into two right triangles, with the right angle buried within the heart of the spine. And so the Adjacent side is not direclty measureable. But hey, that's all hairsplitting and only important if you are swapping data with someone else.

Are you looking more for the appearance and cosmetics of the originals, or actual authenticity in every detail? The reason I ask is that a somewhat thicker spine would be more practical, for honing. You could simply hone with a layer of tape and add another layer for a few finish laps and have as good an edge as the steel will support.

And that brings up another issue. The steel. Modern steels used in razors harden quite well when quenched using optimum temp, soak time, and quenchant, In the 1700's, I think mostly steel was just steel, and any extra included carbon was courtesy of the smith and his forging process. The stubtails I honed certainly seemed to be on the soft side. Most old Sheffield razors are fairly soft. So a true duplicate would be something other than the commonly used O1 or 1095 etc steels. OTOH, if you only want to duplicate them visually, they could certainly be made with a good modern steel and nobody would know the difference just looking at them.

-

09-06-2020, 04:04 PM #7

-

09-06-2020, 04:09 PM #8Senior Member

- Join Date

- Jun 2014

- Location

- Eastern Washington State USA

- Posts

- 406

Thanked: 59

15Likes

15Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote