Results 11 to 20 of 49

Thread: How do not make it worst?

Threaded View

-

11-12-2012, 03:53 AM #1

How do not make it worst?

How do not make it worst?

Hello all good people,

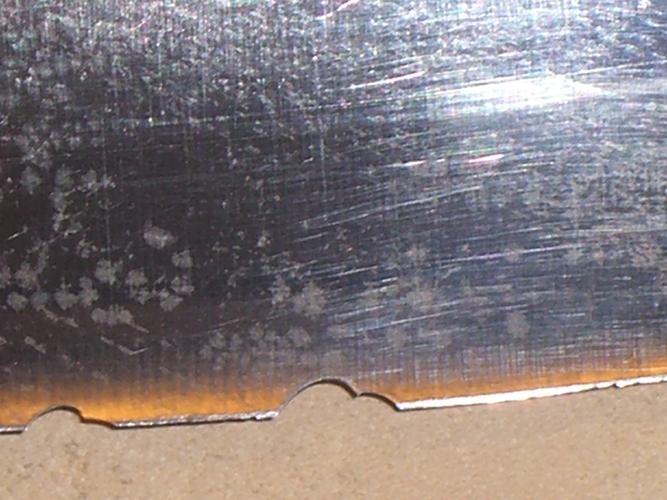

I got this razor recently with idea to fix it as I did it with many other. Problem is it is my first razor, that big razor I will be wotking on. Also it is wedge and I would like to avoid to damage geometry of the blade. How to start repair of this edge? It is bad but I think it can be fix.

34Likes

34Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote