Results 61 to 70 of 73

Thread: Tamahagane nihon kamisori

-

03-01-2013, 04:28 PM #61"My words are of iron..."

- Join Date

- Oct 2006

- Posts

- 1,898

Thanked: 995

Wadsworth and Sherby are hardly the sine qua non of the metallurgical world. There is some volume of European metallurgical work on ultra high carbon steels that is of more interest to this discussion since it involves modern alloys. In some ways their work about the subject we are discussing is a distraction since they are speaking about wootz/bulat which is not tamahagane despite being an ultra high carbon steel. The manufacturing methods are entirely different.

One article alone is not sufficient to make your point. Indeed, the very criteria you want, fine grained steel, becomes a very real problem when the carbon content rises above the eutectic point and sufficient control is not exercised in the working of the steel. These controls are more difficult in more primitive shops (e.g. Japanese smithy's because of the very limiting traditional methods they are required to use, and the very good training their system encourages). That fact does support your contention that the skill is more important than the material. Except, for a hypoeutectic steel, e.g. 0.6% carbon, the grain problem is not such an issue. Perhaps Japanese smiths figured this out and now ritually avoid ultra high carbon steels so as to avoid this problem?

This statement is unsupportable. The swordsmith's methods are exceptionally consistent, backed by a considerable volume of metallurgical testing by the Japanese government. With the exception of one ryu, which consistently produces swords in the 0.71% carbon content they are all between 0.6-0.65% carbon. Using tamahagane that begins with a carbon content at or near 1.5%, that is a considerable amount of carbon lost to produce a desired product that ends near 0.6%. All controlled in the forge. Their reasons are simple. Hamon are better with a lower carbon content. Blades that turn to scrap are less subject to breaking with a lower carbon content. They are no different than any other artists, they don't like to waste time materials or effort any more than any other human being.Carbon content in a japanese sword is around 0.5-0.6 %, letīs not take into account, that (nearly?) all Swords made from Japan are made from different steels with different carbon contents.

I have no evidence of any carbon testing done by the razor makers on the final product, but would be intensely interested if that information was available, just to fill in some gaps in my curiosity. I strongly suspect, given the undoubtedly close relationship between swordsmiths and toolsmiths, and that their methods hold much in common, their products will have similar characteristics and your contention that tamahagane razors are higher in carbon may be inaccurate. I know just who to ask to begin that quest too. But, anyone who can get that information from the Iwasaki-ryu .... I'm interested.

I have no problem with anyone arguing that the steel makes little difference, nor does the hardness when it comes to shaving. It is entirely likely that our honemeisters here, if they were motivated, could put a shaving edge on unhardened steel, even non ferrous metals. Those edges would not last long, but that's the point. Several members here have a clear memory of testing some blades at my shop, that shaved and were only Rc 50. Shaving relies on technique and edge geometry. A durable edge will need hardness and a steel capable of getting hard if it's meant to be a durable edge, not requiring daily honing. 1060 steels are capable of getting hard enough to maintain a durable edge. This returns us to the point that tamahagane is really nothing more than the simplest of iron and carbon with incidental alloys native to the ore, made using nearly medieval methods. Comparing it to modern alloys is too big a stretch to make based on individual steel characteristics subject to change in the hands of a smith.

Personally, I love the stuff because of the challenges. No point in doing something unless it's difficult.

-

03-01-2013, 06:27 PM #62Member

- Join Date

- Jul 2010

- Posts

- 69

Thanked: 13

Ah, I think I wasnīt clear enough here. What I meant was the fact, that they use different steels on one blade, like steel with less C in the back.

AFAIK, people here are talking a lot about the hardness of these Tamahagane razors(when they are honing them), which suggests high carbon content, or a strange way to temper the blades (like nearly no annealing, if it really was 0.6 % C?).

What I find interesting about the Article I posted is the part about superplasticity and the idea about refining the grain. But I think, Iīve lost my point there again, sorry. Granted, itīs long ago, that Iīve read the article. Iīm aware, that you canīt compare Wootz with Tamahagane.

tokLast edited by tok; 03-01-2013 at 06:29 PM.

-

03-01-2013, 09:51 PM #63Member

- Join Date

- Nov 2012

- Location

- Auckland,New Zealand

- Posts

- 35

Thanked: 0 Overseas Tamahaganae

Overseas Tamahaganae

I think that you need to make the steel in Japan by the traditional Japanese fashion.

Walter Sorrels-an American bladesmith is making Japanese blades from scratch(right from making his own steel in the traditional Japanese manner).These blades should be called Nihonto but because he is not an authorized "Japanese" swordmaker living and making in Japan they are only allowed to be called "nihonto styled".They are also every bit as good as the "real" ones and maybe even better.

Bit like the French argument behind Champagne only coming frome the Champagne region in France.

John

-

09-04-2013, 04:43 AM #64Ex-lurker

- Join Date

- May 2013

- Location

- New Delhi (India) / Europe

- Posts

- 48

Thanked: 3

The Iwasaki tamahagane kamisori are still being made by them, though very infrequently. They still have a stock of traditionally prepared tamahagane iron dating from the '70s and don't want to sell it or dispose of it so occasionally they (the Iwasaki apprentice who has now become a master himself) produce a small batch. Prices are high from the start because they have to reject about 50% (extremely difficult to work with it seems). Not easy to come by, i purchased mine from Takeshi and he informed me that he'd only received half the number he had ordered and after a >2year wait. He sold them at a very honest price (and told me he'd kept one for himself, which he normally never does with the items he sells). anyway, he's out of stock now and there's no telling if/when they'll be back.

If you want one, take a look here.

And yes, it shaves like a dream, easily the best of the already high-end Iwasaki line.It is preferable to have a criminal as a servant rather than a fool because a criminal's actions are at least predictable.

-

09-04-2013, 05:17 AM #65I used Nakayamas for my house

- Join Date

- Aug 2009

- Location

- Des Moines

- Posts

- 8,664

- Blog Entries

- 1

Thanked: 2591

According to members that talked to Iwasaki personally they do not make tamahagane razors any more and have not for a long time. Reason is that it is very hard to find quality tamahagane that can be used for razor, vintage tamahagane can be found but because of quality and rarity it is very expensive, something like 200 usd for 100g of it. You can find vintage tamahagane NOS condition in Japan here and there. The smith that makes the Iwasaki razors , Mizouchi San, has been making them for ~15 years now.

Stefan

-

09-04-2013, 05:32 AM #66Ex-lurker

- Join Date

- May 2013

- Location

- New Delhi (India) / Europe

- Posts

- 48

Thanked: 3

The only thing I can say to that is what Takeshi told me and short of hopping on a plane to Japan I guess there's no way to find out. I purchased mine a while ago, came in the usual coffin box but packaged in a white plastic sleeve (the other models I own came in yellow sleeves). Obviously I can't tell how old the razor itself is but it would greatly surprise me if it were 15 years old or more. If the paper wrapper (in Japanese which I don't read) gives any indication of the production date then I'll be more than happy to snap a pic and post it here.

It is preferable to have a criminal as a servant rather than a fool because a criminal's actions are at least predictable.

-

09-04-2013, 11:10 AM #67I used Nakayamas for my house

- Join Date

- Aug 2009

- Location

- Des Moines

- Posts

- 8,664

- Blog Entries

- 1

Thanked: 2591

Kousuke Iwasaki, the founder of the company, went trough a lot of testing to develop a steel that is as close to Tamahagane as possible in qualities and performance so that they do not have to worry about finding quality Tamahagane. The steel is what they call "Spicy Swedish" and is what is used for their kamisori today. Iwasaki also has traditional straights from that steel, as well as from Tamahagane, but they stoped making them in the 1980's.

Stefan

-

09-04-2013, 03:33 PM #68

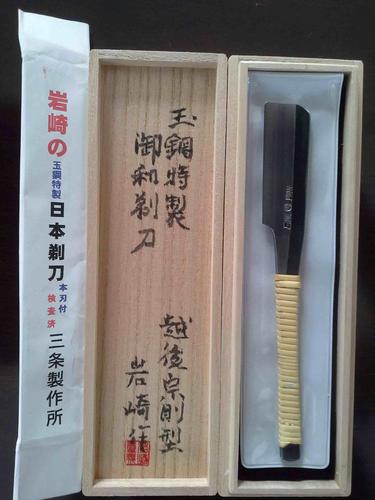

I think this is what xenophon was referencing, about six months ago, Takeshi had a few available for sale.

IWASAKI Tamahagane Echigo Munenori Shaped 58mm bladeJon

-

The Following User Says Thank You to Thisisclog For This Useful Post:

xenophon (09-04-2013)

-

09-04-2013, 09:50 PM #69Ex-lurker

- Join Date

- May 2013

- Location

- New Delhi (India) / Europe

- Posts

- 48

Thanked: 3

Indeed, that's it. I purchased mine a bit before then.

The entire confusion might stem from the fact that a) the tamahagane steel (raw material) is indeed no longer being produced by them since the 70's-80's and they no longer can/are willing/able to do so. But as I said, they still have limited stocks of the steel available and from what I understood they do use that to periodically make a batch of the razors in question. Either that or they keep a stock of tamahagane razors and periodically release small batches to their distributors, which seems a bit unlikely imho. The razors made from it have the 'tama hagane' kanji beaten above the maker's mark on the Ura side. If I'm not mistaken the term is protected in Japan and can only be used with items made from steel produced following the traditional procedure (iron ore sand, hand working in a charcoal fuelled furnace etc). The tamahagane kamisori have a hardness of about 67 HRC. The 'Echigo Munenori' is in honour to a local smith who forged knives and katana and had devised the original shape of the kamisori blade such as is still used by Iwasaki.

The other razors in their line (the 45, 50 and 60 mm) are produced from 'sweden steel', although this might be locally produced Aogami 1 or 2, I don't know. (Akeshi's website claims it might be old Sandvik steel from Sweden) and are A LOT cheaper, easier available and have a slightly lower hardness of about 65 if memory serves.

And t might be psychological but the tamahagane razor is my favourite, came out of the box shave ready and with an incredible edge.

Here's mine (apologies for pic quality):

If you want one and have the coin, by all means grab it now if you can find it at an acceptable price. They won't become easier to find nor cheaper.Last edited by xenophon; 09-04-2013 at 09:52 PM.

It is preferable to have a criminal as a servant rather than a fool because a criminal's actions are at least predictable.

-

09-04-2013, 11:00 PM #70

Around 15 years ago you could order one of those made by iwasaki and they were selling for around 1500-2000USD. of course the yen dollar exchange rate was way more favorable then. At the time I was told his production of those razors went to his dedicated collectors and you needed a "hook" to get one at any price.

No matter how many men you kill you can't kill your successor-Emperor Nero

14Likes

14Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote