Results 11 to 18 of 18

-

03-29-2012, 04:33 PM #11

New SEM images!!!

New SEM images!!!

I got some great news.

After several days of experimenting I finally came up with a way to improve the image quality.

I tilted the blade heavily towards the "camera". It isn't a full 90° edge on view, but kind of a ~70° angle.

This way the SEM gets much more electrons from the edge itself.

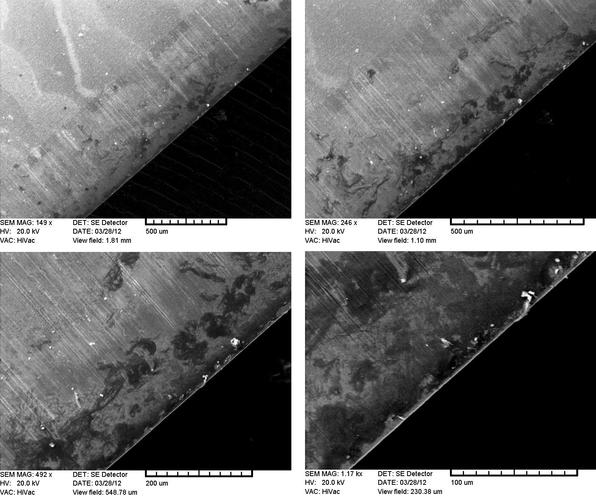

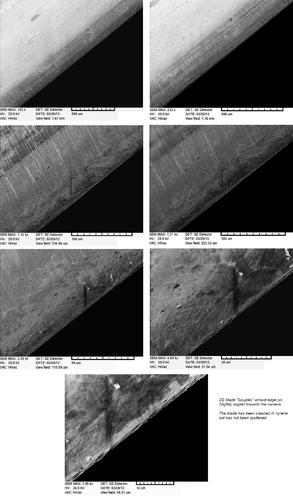

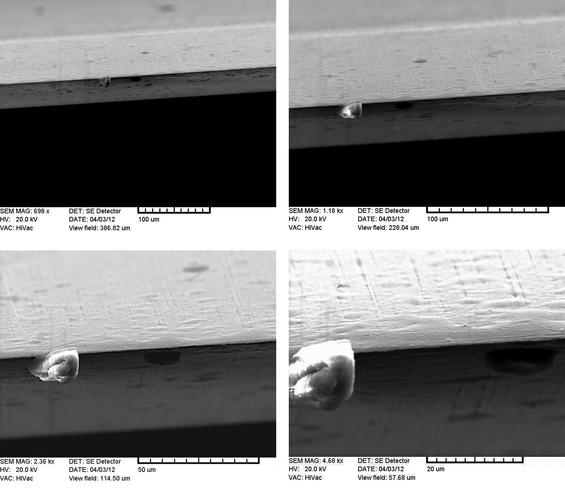

For comparison sake here are two sets of pictures from the same blade, a Souplex DE.

Klick for enlargement

Blade flat:

Blade tilted towards SEM-Detector

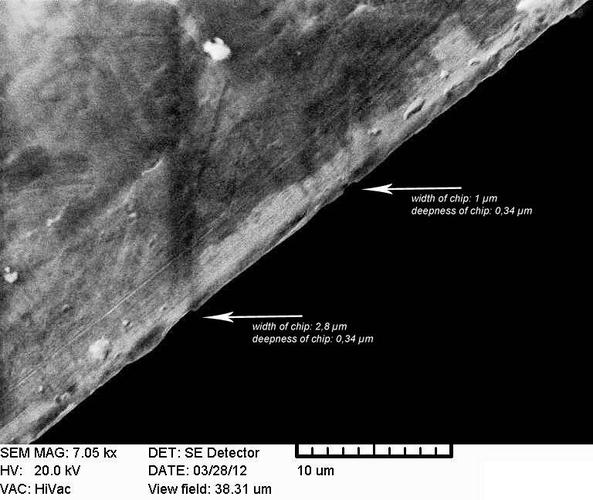

Magnifications to 7.000x and more can be realized this way.

Here, defects become visible

-

03-30-2012, 07:37 AM #12Member

- Join Date

- Feb 2010

- Posts

- 63

Thanked: 5

Very nice. I wonder at what point it becomes irelevant as to imperfections in the edge? I enjoy your work, but even though I (we) strive for perfection, I know it is unachievable. I wish it was.

-

04-03-2012, 02:26 AM #13

Great images. Thanks for sharing. But, wondering if there is anyway to translate these images into how well a blade will shave?

-

04-03-2012, 05:43 AM #14

Hi Ziggy,Great images. Thanks for sharing. But, wondering if there is anyway to translate these images into how well a blade will shave?

Hi Ziggy,Great images. Thanks for sharing. But, wondering if there is anyway to translate these images into how well a blade will shave?

unfortunately there is no way to estimate the performance of a blade only by looking at it,

even under close magnification. The performance of a blade is a function of many variables,

such as geometry of the blade, type of the saftey razor, preparation and type of beard, type of grind and many others among them so called confounding variables like "bad day", or bad technique etc.

But there is still much to learn from these pictures anyway. High magnification just isn't the holy grail of sharpening

-

04-04-2012, 03:20 AM #15

Could you do a shot with a hair up against the edge of the blade? That would be great to see up close.

-

04-04-2012, 06:08 AM #16

Unfortunately no, this is not possible. I get this request a lot but there are some simple reasons.Could you do a shot with a hair up against the edge of the blade? That would be great to see up close.

Unfortunately no, this is not possible. I get this request a lot but there are some simple reasons.Could you do a shot with a hair up against the edge of the blade? That would be great to see up close.

First of all human hair is made of a material that is not condictive like metal.

The surface to be investigated under an SEM needs to be conductive for the electrons to be reflected.

It is possible to make non conductive matrerials visible under the SEM I am using using a sputter coating technique.

Similar has been done here. Check chapter one

Google Books

Now you can understand the second reason. Even though it would be possible for me to sputter coat a human hair,

its sheer size would fill the whole image leaving nothing to see from the actual edge.

A human hair has a diameter of roughly 50µm. It actually is too big to be visible side by side with the edge, that gets interesting at around 1-10µm

-

04-04-2012, 06:24 AM #17

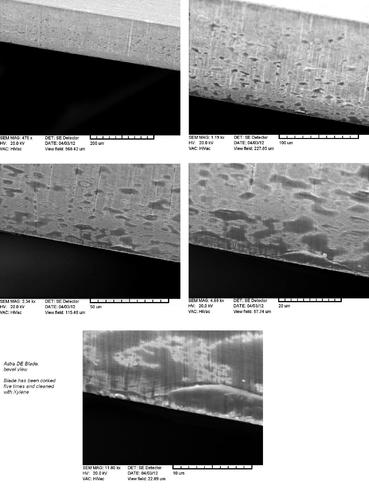

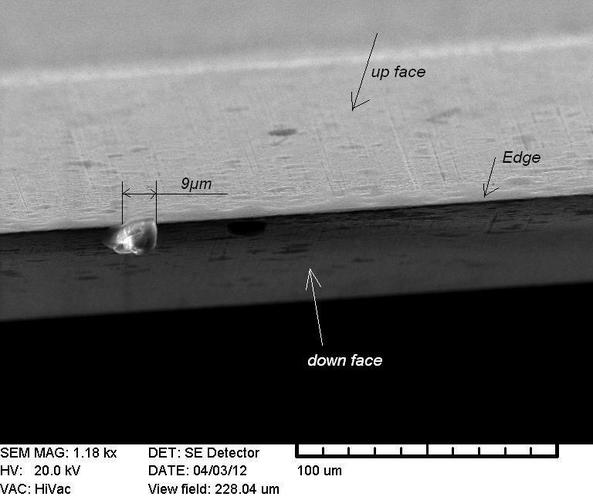

SEM images of an Astra Blade

SEM images of an Astra Blade

New images have arrived. This time an Astra blade has been examined.

The first set of pictures shows the bevel with the blade tilted towards the detector.

The Blade lies not flat to ensure a better view on the edge.

The Blade has been cleaned with Xylene and korked five times.

Klick for enlargement

This time the Astra blade has been cleaned with Xylene, not been korked and

the view is straight down the edge. You are looking directly on the very cutting edge.

Here I added some comments for clarification

-

The Following 3 Users Say Thank You to Lesslemming For This Useful Post:

alx (04-11-2012), Deegee (05-15-2014), ScottGoodman (06-26-2015)

-

04-07-2013, 07:46 PM #18

Is that a spot of rust on the astra in the last pic?

25Likes

25Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote