Results 21 to 30 of 41

Thread: Soft Steel Razors

-

09-05-2020, 04:48 PM #21

Coil springs are often 5160 which is .6% carbon, but importantly the added chromium lowers the eutectoid of that alloy to .6 %. In plain carbon steels the eutectoid is closer to .8 %. At the eutectoid, most of the carbon can be in the martensite leaving little to form, hard to abrade, carbides.

Last edited by bluesman7; 09-05-2020 at 04:53 PM.

-

09-05-2020, 06:31 PM #22Senior Member

- Join Date

- Jun 2014

- Location

- Eastern Washington State USA

- Posts

- 406

Thanked: 59

I re-honed it and gave it another try, same results. It got dull at the exact same point in the shave. A few licks on the strop and it was shaving again. The steel is simply not at the correct hardness anymore. Either it was overheated at some point in time, or it was "case hardened" and has been worn/ground down past the proper temper. I'll still keep it and use it from time to time though.

-

09-05-2020, 07:15 PM #23

I once had a vintage razor that would not hold a 16° edge, but it would hold a 17° edge. Have you measured the bevel angle?

-

09-06-2020, 01:39 AM #24Senior Member

- Join Date

- Jun 2014

- Location

- Eastern Washington State USA

- Posts

- 406

Thanked: 59

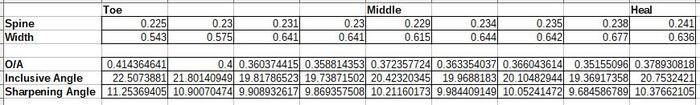

Interesting thought. It is so worn and uneven that it is a bit of a challenge to get a good measurement. Depending on where I measure, I get anywhere from 19.3 - 22.5. This to me indicates that it used to be considerably wider. It is honed with two layers of tape (as per the instructions that it came with). Now, I could re-hone it with no tape.

-

09-06-2020, 12:24 PM #25

Some people don't mind those obtuse angles, but I've never had a shave from a >19° edge that was better than meh.

Are you saying that those are the angles without tape, and then you're adding two layers?????Last edited by bluesman7; 09-06-2020 at 12:59 PM.

-

09-06-2020, 01:28 PM #26Senior Member

- Join Date

- Jun 2014

- Location

- Eastern Washington State USA

- Posts

- 406

Thanked: 59

Those angles are with the tape. If I removed the tape, I my barely be within the "normal" range. You are correct about the shave quality. Meh is a good description.

-

09-19-2020, 11:45 PM #27Senior Member

- Join Date

- Jun 2014

- Location

- Eastern Washington State USA

- Posts

- 406

Thanked: 59

Well the smoke has cleared out of the air. So I fired off the forge and turned a coil spring into a flat tapered piece of steel. Here it is after being pounded out and rough ground. There is still a ways to go yet.

-

09-21-2020, 02:39 AM #28Senior Member

- Join Date

- Jun 2014

- Location

- Eastern Washington State USA

- Posts

- 406

Thanked: 59

I have the basic shape done as well as the pivot hole. Now to take some measurements and figure out the edge grind.

-

09-22-2020, 12:24 AM #29Senior Member

- Join Date

- Jun 2014

- Location

- Eastern Washington State USA

- Posts

- 406

Thanked: 59

Not a very good picture, but it is ground enough to heat treat it. Hopefully I don't mess that part up, because so for it is turning out fairly well. Has anybody seen a replica 1700's razor recently? I can't think of any.

-

09-22-2020, 02:22 AM #30

Looking pretty good, so far.

Notice the smile to the entire bottom if the bladeLast edited by outback; 09-22-2020 at 02:24 AM.

Mike

67Likes

67Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote