Results 1 to 6 of 6

Thread: Frederick Reynolds Frameback

Threaded View

-

10-07-2013, 04:22 PM #1

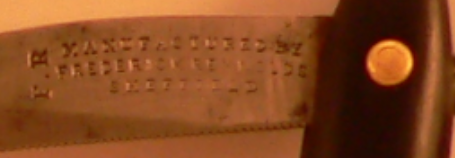

Frederick Reynolds Frameback

Frederick Reynolds Frameback

I've just done a bit of cleaning with Mothers and a Scotchbrite wheel on my dremel, hence the "brushed steel" finish.

This is a tad over 6/8" at its widest, the scales are perfect, and just a tiny bit of pitting at the toe.

I really don't want to do too much more to this, but I'm always open to suggestions.

Please excuse the poor pics !!

http://straightrazorplace.com/workshop/18504-welcome-workshop-how-do-i-where-do-i-what-do-i-answers-here.html

http://straightrazorplace.com/workshop/18504-welcome-workshop-how-do-i-where-do-i-what-do-i-answers-here.html

3Likes

3Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote