Results 21 to 30 of 33

Thread: Cerium Oxide for smoothness

-

08-09-2013, 10:22 AM #21< Banned User >

- Join Date

- Dec 2012

- Location

- Long Island NY

- Posts

- 1,378

Thanked: 177

Well I tried some crox on my phig. The edge felt about the same so no benefit there. Cleaned and lapped it and applied .1 cbn spray. Same thing. I got a better result from using crox on linen after the phig. Not scientific but in line with whats been said before. My best edge out of it all was phig, then linen crox then cbn on hard wool.

-

08-10-2013, 03:54 PM #22

Agreed. Like Glen said, a few years back some of us experimented with Crox, CBN and Diamond spray, primarily on Phig's or Chinese 12k's. Nothing really earth shattering. As mentioned these products excel on felt, leather, balsa and the like.

I don't think I've tried Cerium, but have tried all the others mentioned. Is it really worth it? Will the results be much more noticable than CBN .160, or Crox or even Diamond. Now, I know Diamond can be harsh at the .25 level, The Cbn .160 was surprisingly smooth to me, as is crox.

TBH, I haven't use any of these in some time.Last edited by zib; 08-10-2013 at 03:58 PM.

We have assumed control !

-

08-10-2013, 09:59 PM #23Senior Member

- Join Date

- Apr 2012

- Location

- Diamond Bar, CA

- Posts

- 6,553

Thanked: 3215

What do you mean to hone on?

I have stropped on it for years to experiment with, it works well just like hard felt, but not a good as Foam or Paper.

I'm wondering if that type of felt is firm enough to hone on. I have some felt from SRD and two other sources and the surface is a bit firmer than the Wal-Mart stuff. If anyone has had success with the W-Mart felt, please post.

-

08-27-2013, 12:26 PM #24

Just wondering what micron super cerium is and how it compares to .3micron alumina 'a' oxide?

My wife calls me......... Can you just use Ed

Can you just use Ed

-

08-27-2013, 03:46 PM #25Junior Member

- Join Date

- Jul 2013

- Posts

- 9

Thanked: 1

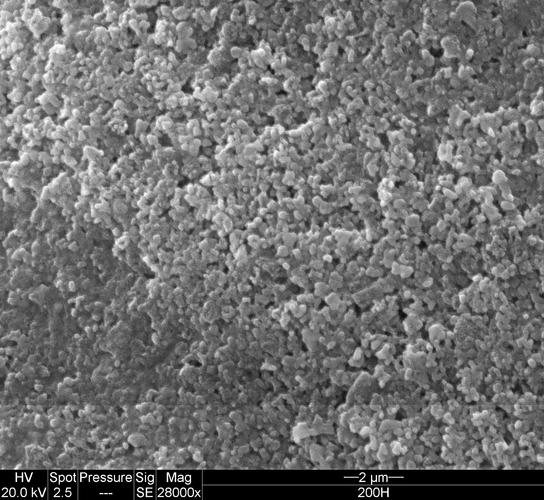

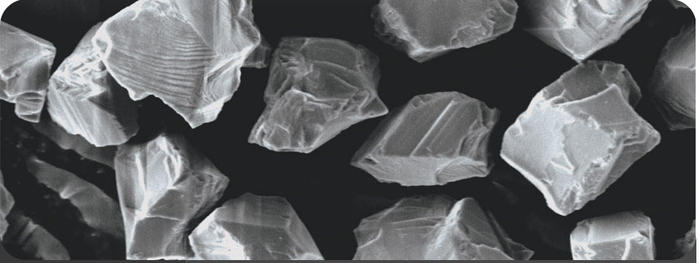

The real difference is not in particle size but shape. Aluminium oxide is usually very cube shaped when viewed under an electron microscope. Cubic and uniform in shape is the best way to describe it. The corners will round off over time which will affect the cutting characteristics. With Al0x this rounding of the corners happens pretty quick by comparison to nearly all other abrasives.

Cerium oxide, by comparison, is platey and very thin. There are no real sharp corners to do any cutting so it has the habit of smearing the polishing surface rather than cutting it with sharp corners. This probably explains what others have said about CeOx not increasing the sharpness of their razors. Another point is that CeOx is very friable. It breaks down into smaller and smaller particles with use. Cerium oxide also has a peculiar action of polishing finer than the grit size suggests.

-

08-27-2013, 04:09 PM #26Junior Member

- Join Date

- Jul 2013

- Posts

- 9

Thanked: 1

Here are some photos comparing Aluminium oxide and Cerium oxide. Look hard at the CeOx, it just doenst have any sharp corners to it.

-

The Following User Says Thank You to DaveJ For This Useful Post:

eddy79 (08-28-2013)

-

08-28-2013, 10:43 PM #27

Since this thread is slowing let me put a spark in it.

Have any of you tried Zirconium oxide?No matter how many men you kill you can't kill your successor-Emperor Nero

-

08-28-2013, 11:09 PM #28Junior Member

- Join Date

- Jul 2013

- Posts

- 9

Thanked: 1

Exotic stuff that is. I typically associate it with sapphire polishing but I know it is aimed at the metal polishing market too. Some of the bigger raw suppliers offer dispersions with particle size as small as 15 nanometers. Damn thats small. The product is not particularly pure, even in the electronic and optical grade product. This usually means that the source crystal that they mill the powder from will be polycrystalline, not single crystal. Single crystal source material always offers better shape characteristics and it will almost always last longer. Also, single crystal is usually not as friable as poly.

I have no personal experience with this product but I did take the time to go thru my suppliers technical data sheet before sending this reply.

-

08-29-2013, 12:36 AM #29

Though poly won't last as long for some applications it's what you want. It will breakdown and become finer and finer as you use it.

No matter how many men you kill you can't kill your successor-Emperor Nero

-

09-01-2013, 11:49 PM #30

10Likes

10Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote