Results 1 to 10 of 32

Thread: My stropping experiment

Hybrid View

-

03-05-2012, 11:33 PM #1

That is what I think also. I have used the strop once and it has no draw. Hardly any resistance. No friction in my mind equals no heat so it would even take that possibility out of the question. It is very soft so I have a hard time believing it does much of anything. That being said I used it last night for the first time. I used to many variables to determine anything but the shave was fine so it didn't hurt anything.

Each of these strops cost me about as much as 4 Sunday papers so cost isn't much of an issue.

TimLast edited by 32t; 03-05-2012 at 11:35 PM.

-

03-05-2012, 11:44 PM #2This is not my actual head.

- Join Date

- Nov 2009

- Location

- Middle of nowhere, Minnesota

- Posts

- 4,624

- Blog Entries

- 2

Thanked: 1371

Tim, you are nuts! Hehehe.

I am looking forward to your conclusions on this...

What did you use to sew the strops?

Strange women lying in ponds distributing swords is no basis for a system of government.

-

03-05-2012, 11:51 PM #3

I use graphite as a lubricant on my bass bridge to keep the strings from grabbing during installation or tuning. That is also why it is used on the wheels of your pinewood derby car.

-

03-06-2012, 12:08 AM #4

I think Lynn brought up putting graphite on a strop. I tried it, and probably won't repeate because it leaves black on the towel. Does make it nice and slick though.

-

03-06-2012, 12:22 AM #5

-

03-06-2012, 02:55 AM #6

A short tutorial

A short tutorial

Getting this thing posted is more work than the strops. :-]

I had some questions about how I did this and I was short one D ring from the 2 3/4 inch strop so I decided to finish it and take some pictures.

First I measured

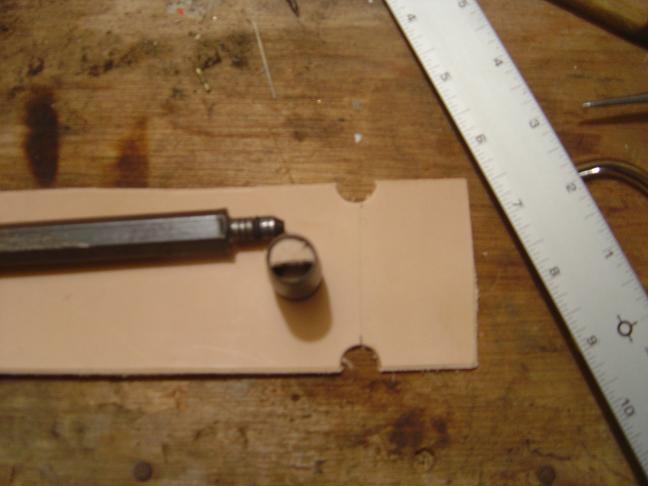

Then I used a 1/2 inch punch to make some partial holes. For the the 3 inch strops the holes were bigger.

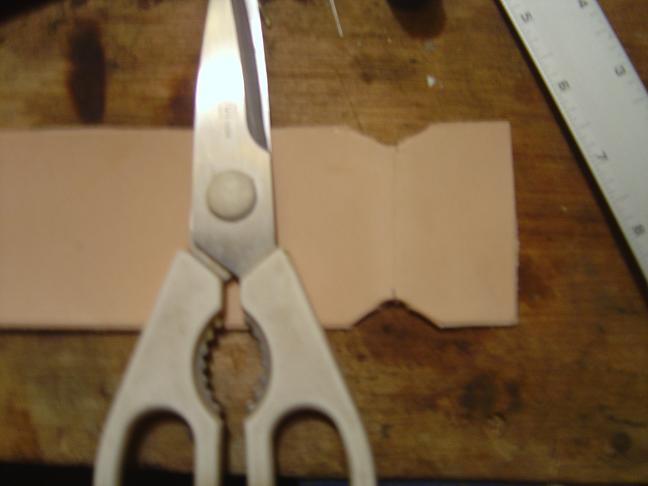

Then I folded it and cut the rest of the V's with a scissors

Next put on some contact cement to glue.

Next, marking my lines and the tool I used to punch the holes. It is not relly a punch. It splits the leather for the hole and allows the leather to close back up after stitching. The marks are very important, at least to me!

My block of wood and the basement floor. Not very ergonomic!

Another view on the bench.

The final product with some of the tools next to the one I put graphite on. I decided to mark them in the rectangles although I don't think that I will forget which one has graphite on it.

I hope this helps and answers some of your questions.

Tim

-

The Following User Says Thank You to 32t For This Useful Post:

xMackx (03-06-2012)

-

03-07-2012, 04:06 AM #7

I now have applied 4 different leather treatments. Lexol, Nor-v-gan shoe oil, Neatsfoot oil, and Mink oil. that is the order of my first impressions with the Mink oil the best. I have a piece of CroMoly roll cage tubing in a vise to burnish them with. 1 1/2 inch in diameter. [I wouldn't use anything else!

]. I put about 500 strokes/rolls on each of the first three. The Mink oil I got to 300 and my arms were tired. Much more draw. The strop and tube were warm.

]. I put about 500 strokes/rolls on each of the first three. The Mink oil I got to 300 and my arms were tired. Much more draw. The strop and tube were warm.

I had a good shave today but I stropped on all of them to test the draw etc. No conclusions yet!

Tim

-

03-07-2012, 04:25 AM #8

I work lather into my strop with a glass bottle on a flat surface. Adds a lot of draw and leaves it very supple, something you won't wanna do until you try it kind of thing.

-

03-08-2012, 12:57 AM #9

you deffinityl lost me on ths experiment i just a plain leather and linen strop and a barber hon to keep my razor runnign smooth and ive had alot of luck so far. let us know how this goes.

-

03-06-2012, 12:34 AM #10

First I glued them together with contact cement. Then I used a 4 prong thonging chisel to make the holes. Then hand sewn with waxed thread.

Not hard to do but I could certainly tell the first one from the last. One thing I learned is in the future I should use a more ergonomically designed piece of fire wood and a pad for my rear while sitting on the floor of my basement punching holes.

Tim

-

The Following User Says Thank You to 32t For This Useful Post:

HNSB (03-06-2012)

23Likes

23Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote