Results 11 to 20 of 21

-

10-18-2013, 10:51 PM #11

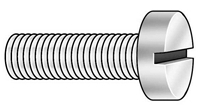

Screw sizes for removable blade framebacks.

Yesterday PS. Have appointment with clockmaker for Friday! Watch?? this space.

Well, the clock maker checked the screw sizes. against his screw cutting dies. (Jewelers' screw plate)

The answer was that most were / are Metric 2.5mm diameter x 0.5 thread. With a socket head they are at your local hobby shop.

And...some are 2.5mm diameter by 0.45mm threading. They are available on line and mostly from sources on the 'bay in packs of 50 or 100 or so for cheap price.

And all were about 5-6mm long.

I used: (Screw, 2.5mm 0.45mm) for a search on the "Bay

~Richard

PS. Cheese head would be the closest to historical usage. ( My guess was many have been replaced over the years )

Have fun!

PPS. I just ordered a pack of the 2.5'x 0.45 pitch. Will send out some if needed. PM me if so. Will have by the end of the month. Nov.1 or soLast edited by Geezer; 10-18-2013 at 11:13 PM. Reason: added info

Be yourself; everyone else is already taken.

- Oscar Wilde

-

The Following 2 Users Say Thank You to Geezer For This Useful Post:

AirColorado (10-19-2013), BobH (10-19-2013)

-

10-19-2013, 05:01 PM #12

Great job finding this! Out of curiosity, I just double checked and the TI set screw on the blade I'm looking at seems about that size but the screwdriver slot is at the top of the screw itself - not in a head - just a straight screw with a slot at the top. Have you come across any without a head of sorts? Hope I'l never need a replacement, but if I ever do now I know where to look.

-

10-19-2013, 11:25 PM #13

Yes, some of them have the screw almost invisible in the spine. That may have been the original way to do it. The screwdrivers furnished were watchmaker set screw sized or some were slightly larger which would then have required a head on the screw to tighten them.

Hone it and enjoy it!

~RichardBe yourself; everyone else is already taken.

- Oscar Wilde

-

10-20-2013, 05:30 PM #14

Thanks Geez - about the oil, I ordered an 8oz can of Kroil from a guy on the bay from MO and it got here 2 days later. The TI is now sitting on my bench with the screw off (and safely stowed). I put a few drops of Kroil into the screw hole and noticed that it quickly worked its way down inside the frame. So I'm letting it work for a few hours sitting spine down. We'll see how well it works later on.

-

10-21-2013, 06:22 PM #15

Well new day, new week, same stuck TI blade... The Kroil went in well, spread quickly under the frame and sat overnight. This morning, same well stuck blade. I had a momentary urge to partially wrap the frame in leather, put it into my vice and start slamming the back of the blade with a rubber mallet - but I resisted. Since I have a few other stuck frameback blades in other razors I figured I might as well slow down and work this through logically - though a blowtorch is tempting.

Any ideas?

As you can see, the blade is in good shape. There was some minor rust that I brushed out but can't see any now anywhere. Bad picture but you can get the general idea below. That little thing below the blade is the lock screw that I'm protecting.

Last edited by AirColorado; 10-21-2013 at 06:25 PM.

-

10-21-2013, 06:26 PM #16Senior Member

- Join Date

- Mar 2012

- Location

- Thunder Bay, Ontario, Canada

- Posts

- 17,367

Thanked: 3228

I dunno, how about alternating freezing and warming cycles with some light taping?

BobLife is a terminal illness in the end

-

The Following User Says Thank You to BobH For This Useful Post:

AirColorado (10-21-2013)

-

10-21-2013, 06:30 PM #17

The blade tilts out with the tang end of the blade coming out last. I have hand held the spine and gently tapped the toe of the blade away from the spine to get some wiggle to start the process. After the first ones, I did use more force. If you consider the holding materials as a glue of sorts, you will be correct. They are not really hard but are sticky! Years of soap and corrosion will be a really strong glue to hold that blade.

I see the grub screw / set screw you described.

Keep on keeping on!

~RichardBe yourself; everyone else is already taken.

- Oscar Wilde

-

The Following User Says Thank You to Geezer For This Useful Post:

AirColorado (10-21-2013)

-

10-21-2013, 07:55 PM #18

Thank Richard, I'll try moderate tapping on the front to see if that starts things. I did just remove the scales (seem to be ebony) to allow a better grip. Also took some dental floss to what gaps exist between blade and frame and MAN there's a lot of crap in there!!! Made the mistake of looking down into the screw hole with a lighted magnifier - yup, some serious "human glue" in there. Let you know later how the moderate tapping works. I think I now know why whomever let this go did so.

-

10-21-2013, 08:18 PM #19Senior Member

- Join Date

- Mar 2012

- Location

- Thunder Bay, Ontario, Canada

- Posts

- 17,367

Thanked: 3228

If you can get a hold of an old dental pick or something similar it might do a better job than the dental floss in the crevices.

BobLife is a terminal illness in the end

-

10-22-2013, 03:39 AM #20

Yup, if someone put the blade in there, It is possible to get it out! You only know if you hit it too hard if it breaks!

~Richard

The blade has a v notch where the set screw enters and wedges it upward, each razor is a little bit different but all of this type have the notch and how much metal above it changes by the spine used,

Be yourself; everyone else is already taken.

Be yourself; everyone else is already taken.

- Oscar Wilde

-

The Following 2 Users Say Thank You to Geezer For This Useful Post:

AirColorado (10-22-2013), Deegee (10-24-2013)

24Likes

24Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote